Method for manufacturing large-scale glass fiber reinforced plastic tank body block

A technology of glass fiber reinforced plastic tanks and manufacturing methods, which is applied in the direction of large containers, containers, packaging, etc., can solve the problems of large space occupied by molds, large molds used, and large investment in equipment, and achieve low production costs, simple production processes, and fewer operators. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

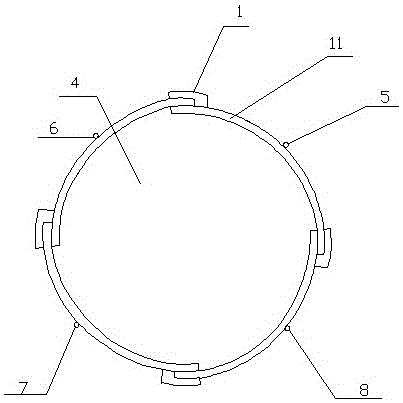

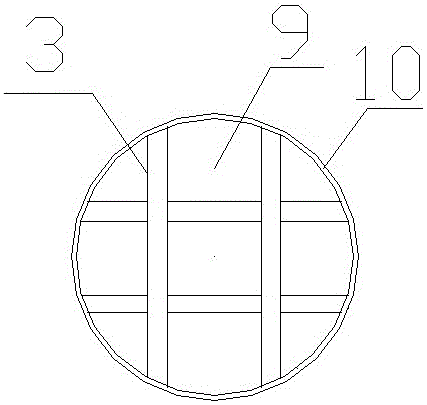

[0021] A manufacturing method of a large FRP tank grill according to the present invention comprises a circular grill 4 made of FRP, with a protruding strip-shaped edge 10 on one side of the circumference of the grill 4, and a "well-shaped" reinforcement is arranged on the inner side of the edge. Rib 3, and use glass fiber cloth and unsaturated polyester resin to bond "well-shaped" reinforcing rib 3 and circular lattice side 9 into one, and process it.

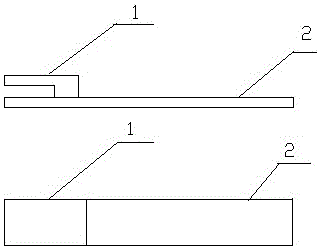

[0022] Preparation and production of the required tools, when the tank grille 4 is processed, several plywood strips 2 with a width of 10 cm are used, one end of which is made into a U-shaped buckle 1 with a built-in three-ply strip, buckle 1 and another three-plywood The ends of the bars can be engaged, and some three-ply planks with U-shaped buckles can be connected end-to-end successively. During processing, draw a circular figure equal to the diameter of the large FRP tank body on the level ground, calculate and make a thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com