Atomic layer deposition device

An atomic layer deposition and equipment technology, applied in the coating, metal material coating process, gaseous chemical plating and other directions, can solve the problems of reducing equipment cost, complex spray structure, unfavorable maintenance, etc., to improve manufacturing difficulty, simplify The internal structure and the effect of uniform and dense growth film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

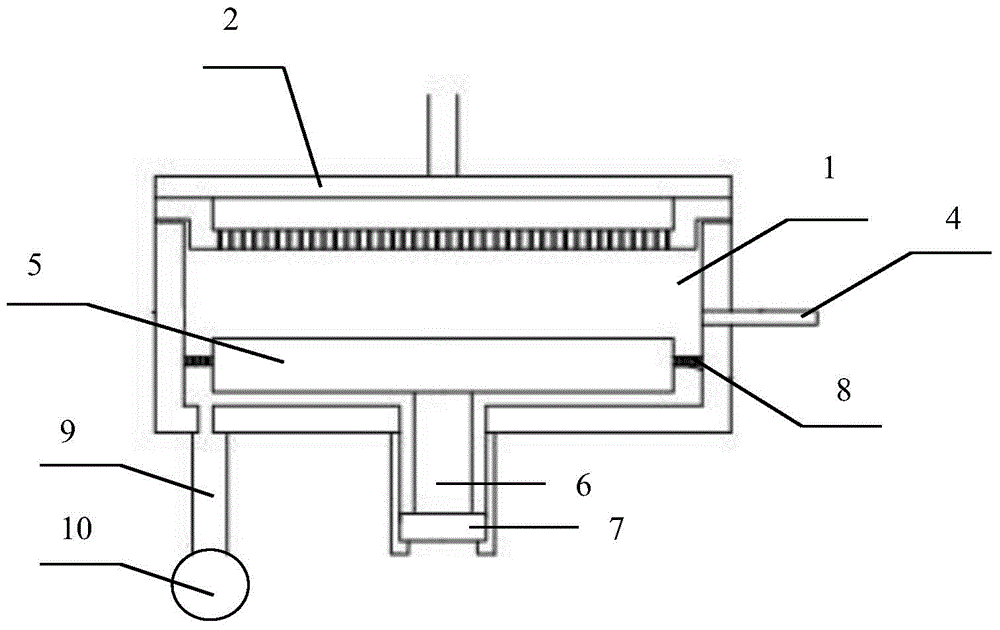

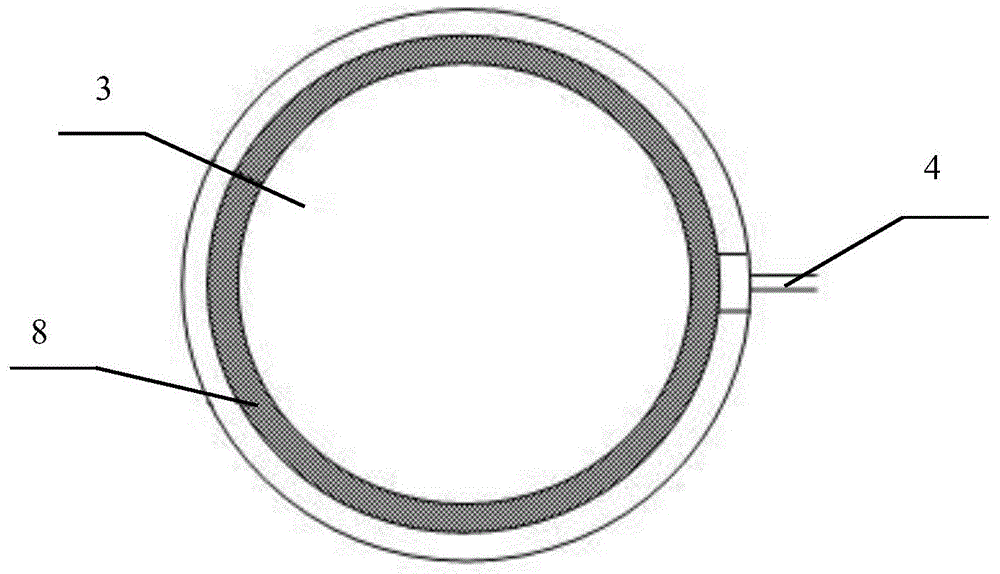

[0021] refer to Figure 1-2 , an atomic layer deposition equipment, comprising a reaction chamber 1, a spray device 2, a heating plate 3, the heating plate 3 includes a heating plate surface 5, a straight handle 6 and a heating plate base 7; the device also includes a side wall The air inlet pipeline 4, the restrictor bushing 8, the vacuum pipeline 9 and the mechanical pump 10; the spray device 2 is installed on the top of the reaction chamber 1, the heating plate surface 5, the straight handle 6 and the heating plate base 7 After being welded and fixed, the heating plate base 7 is installed on the bottom of the reaction chamber 1 with screws; the air inlet pipeline 4 on the side wall is connected to the reaction chamber 1 through screws or welding, and the outer edge of the flow-limiting bushing 8 is connected to the reaction chamber through screws. 1 is fixed inside, the heating plate 3 is not in contact with the restrictor bushing 8, one side of the vacuum pipeline 9 commun...

Embodiment 2

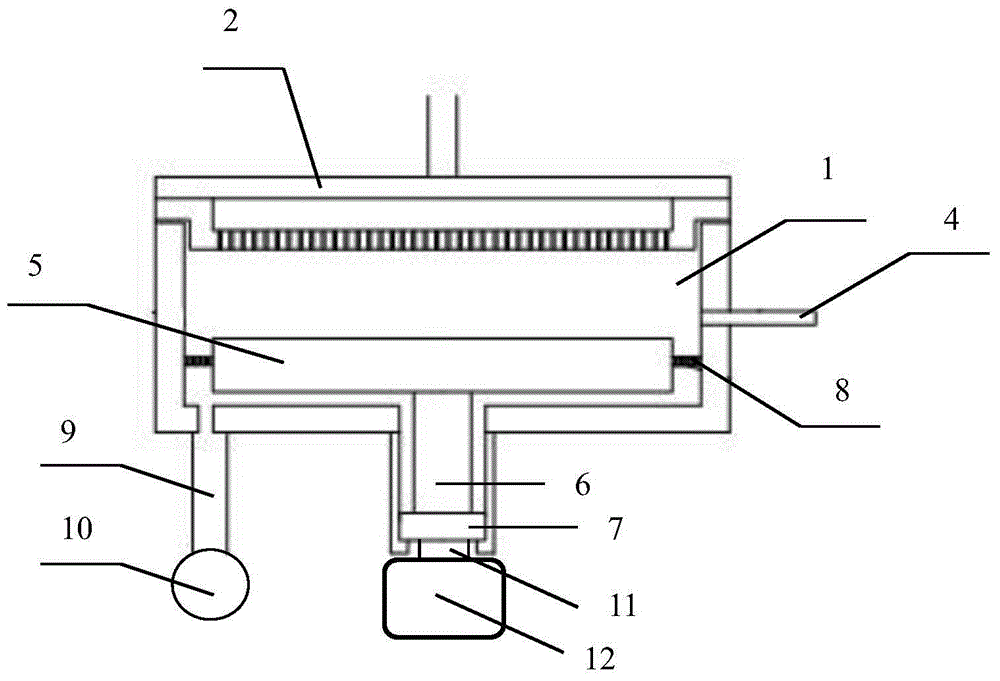

[0028] refer to Figure 2-3 , an atomic layer deposition device, the difference from Example 1 is that the heating plate base 7 is connected to the reaction chamber 1 by using screws under the reaction chamber to connect with the motor 12, and the heating plate base 7 It is connected with the base 11 of the motor 12 to realize that the heating plate base 7 can move up and down or rotate by itself in the reaction chamber 1 . During operation, when the mechanical pump 10 discharges the gas in the reaction chamber 1 through the vacuum pipeline 9, a vacuum will be formed inside the reaction chamber 1. The bottom will fit closely with the reaction chamber 1 so as to achieve the effect of sealing. Turn on the motor 12, move the heating plate 3 to the corresponding reaction position and fix it through the rise or fall of the heating plate base 7, rotate at a preset speed, and then pass a reaction gas through the nozzle on the top of the reaction chamber 1 The shower device 2 enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com