Pool axil angle steel wire mesh template construction method

A construction method and technology of steel wire mesh, applied in formwork/formwork/work frames, swimming pools, public buildings, etc., can solve problems such as cavities, improve structural performance, improve pouring quality, and facilitate disassembly and fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

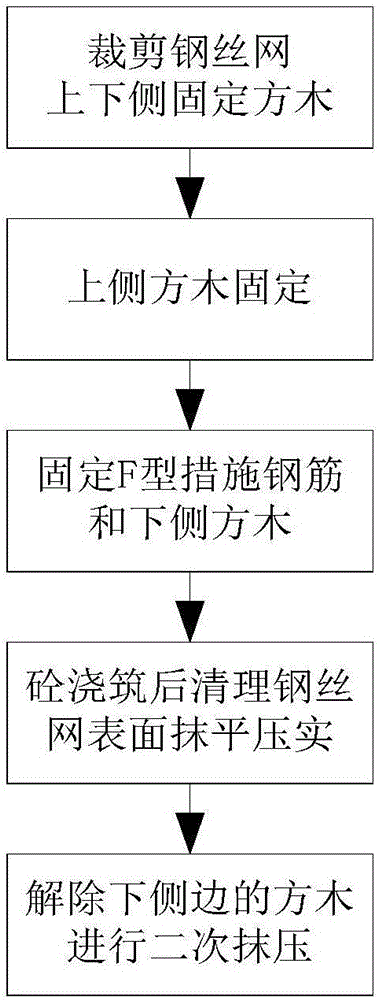

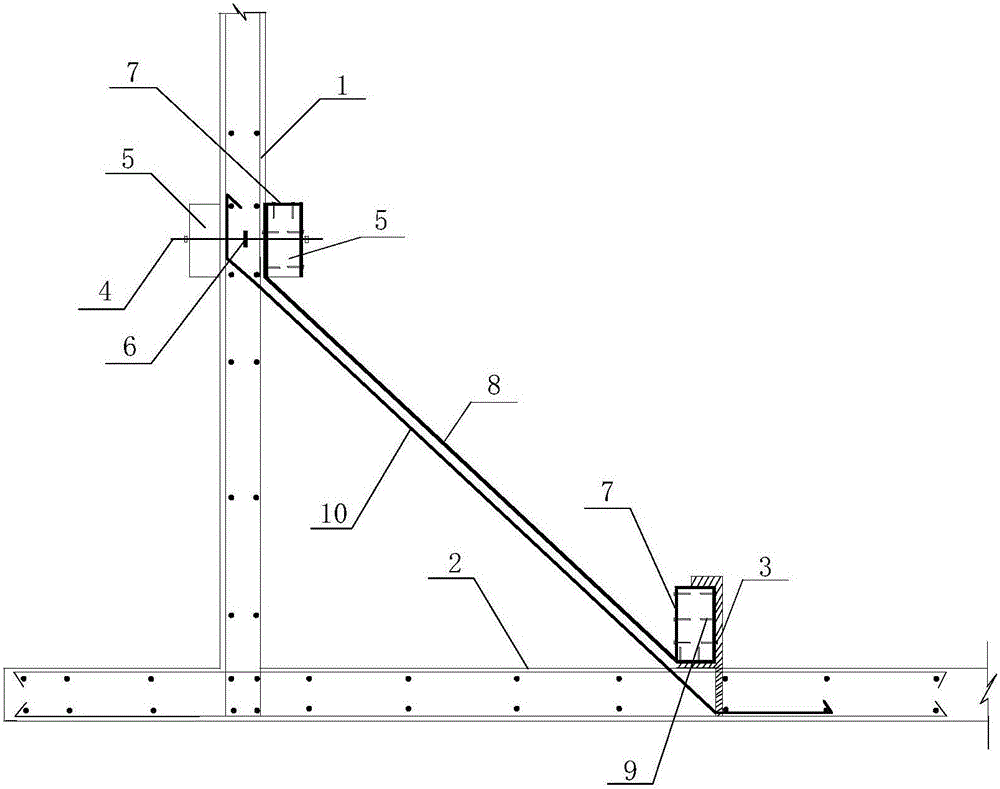

[0023] Such as figure 1 As shown, the pool axillary angle steel wire mesh formwork construction method of the present invention, the pool axillary angle steel wire mesh formwork is formed by turning up the formwork in the pool wall, the bottom reinforcement frame, the F-type measures steel bar, the pull screw, two wooden horizontal bars up and down, Composed of steel wire mesh and diagonal tension bars; among them, the upturned formwork in the pool wall and the steel bar frame at the bottom of the pool are vertically intersected and arranged at the axillary corner of the pool; the upper and lower edges of the steel mesh are wound on the upper and lower wooden horizontal bars respectively; It is used to fix the upper wooden horizontal bar on the upturned formwork in the pool wall; the lower end of the F-shaped measure steel bar is fixedly installed on the steel bar frame at the bottom of the pool; the lower wooden horizontal bar is fixed in the bayonet of the upper end of the F-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com