An internal card type hydraulic cylinder for tensioning deep buried anchors

A technology of hydraulic cylinders and deep-buried anchors, which is used in fluid pressure actuating devices, construction, bridge construction, etc., can solve the problems of inconvenient extending into the anchor hole, time-consuming and laborious threading of steel strands, and heavy tool anchors. The effect of anchoring reliability, reducing labor intensity and reducing bridge cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

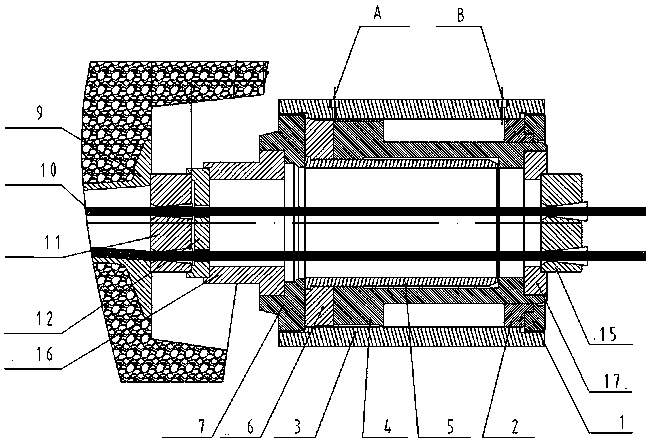

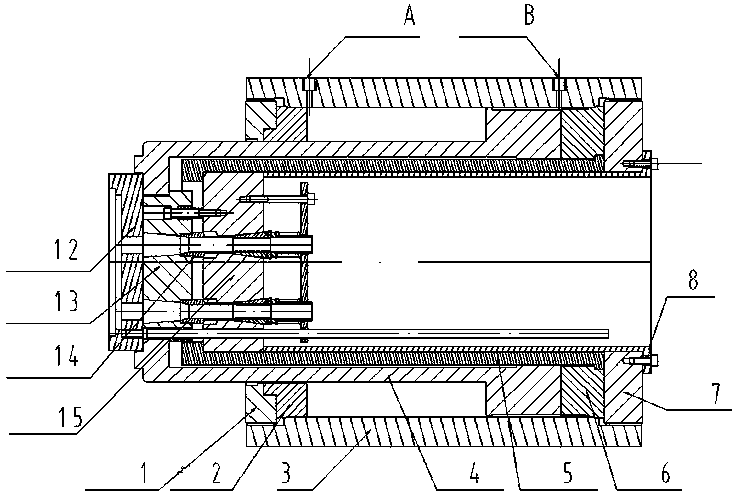

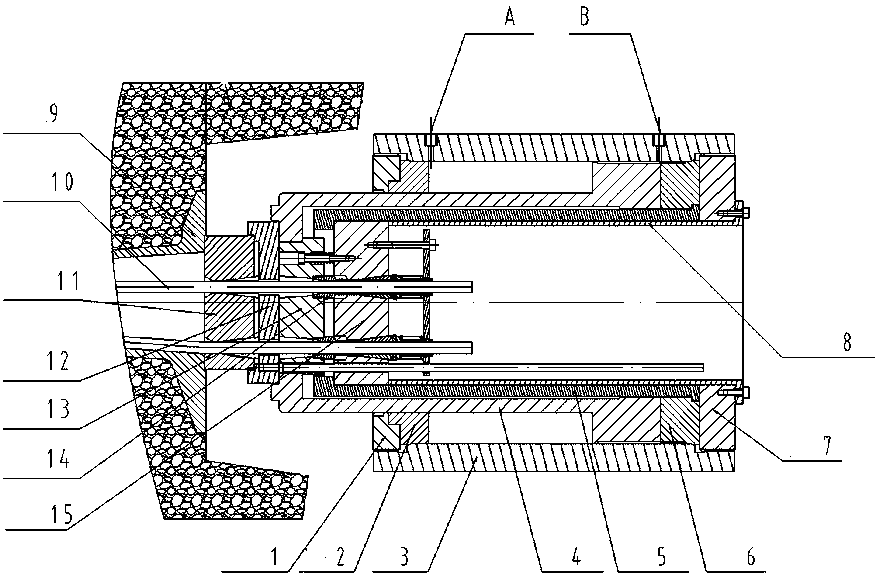

[0014] Such as figure 1 As shown, the present invention includes a limiting plate 12 and a tool anchor 15, and a hydraulic cylinder composed of a cylinder 3, a piston 4, a front end cover 1, a front sealing ring 1, a rear sealing ring 6, and a rear end cover 7; the piston 4 is installed In the middle position inside the cylinder barrel 3, the piston rod of the piston 4 protrudes from the front end cover 1, and the length is more than 100mm, and the inner hole end of the piston rod end has a step; Ring 1, rear seal ring 6, rear end cover 7, a through sleeve 5 is installed inside the piston 4, the through sleeve 5 and the hydraulic cylinder form an internal card type hydraulic cylinder for deep buried anchors; the through sleeve 5 is a A cylinder concentric with the piston 4 of the hydraulic cylinder. A step is provided on the inner circle of the cylinder at the end close to the front end cover 1. A tool anchor 15 is placed on the end close to the front end cover 1 of the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com