A horizontal continuous impact test device and test method

An impact test and horizontal technology, applied in the field of mechanical environment test, to achieve the effect of good use effect, novel and reasonable design, and flexible adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

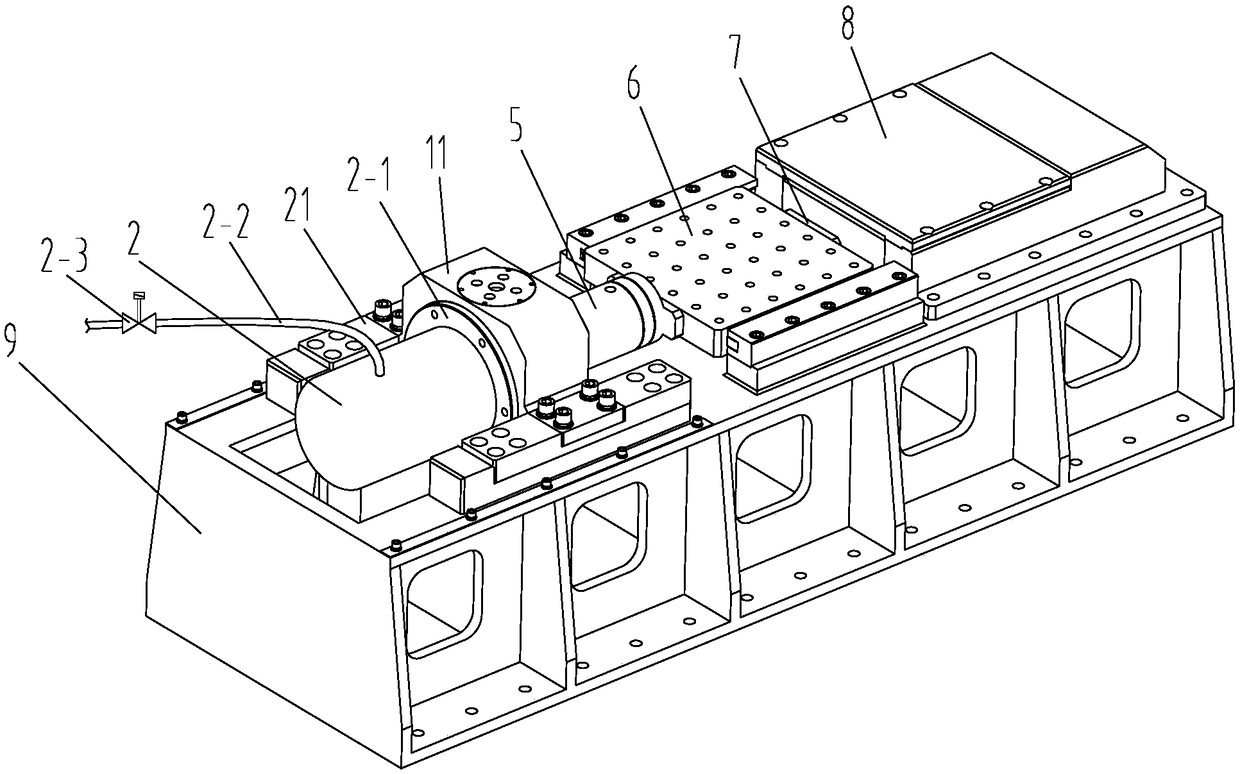

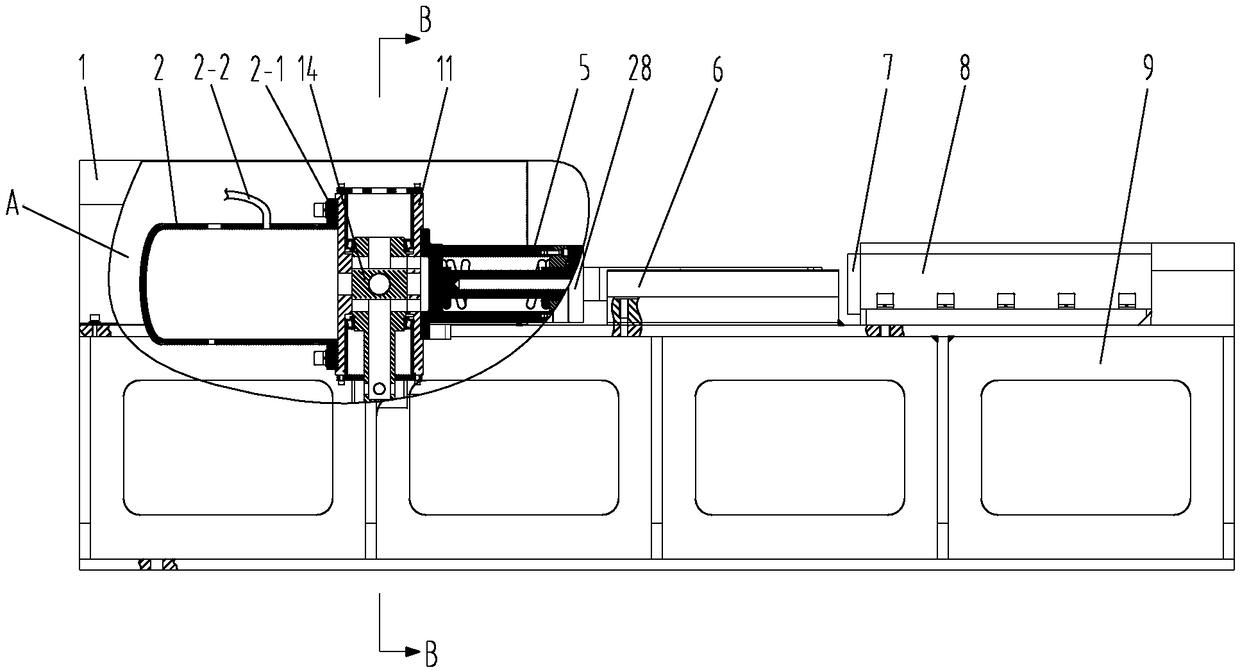

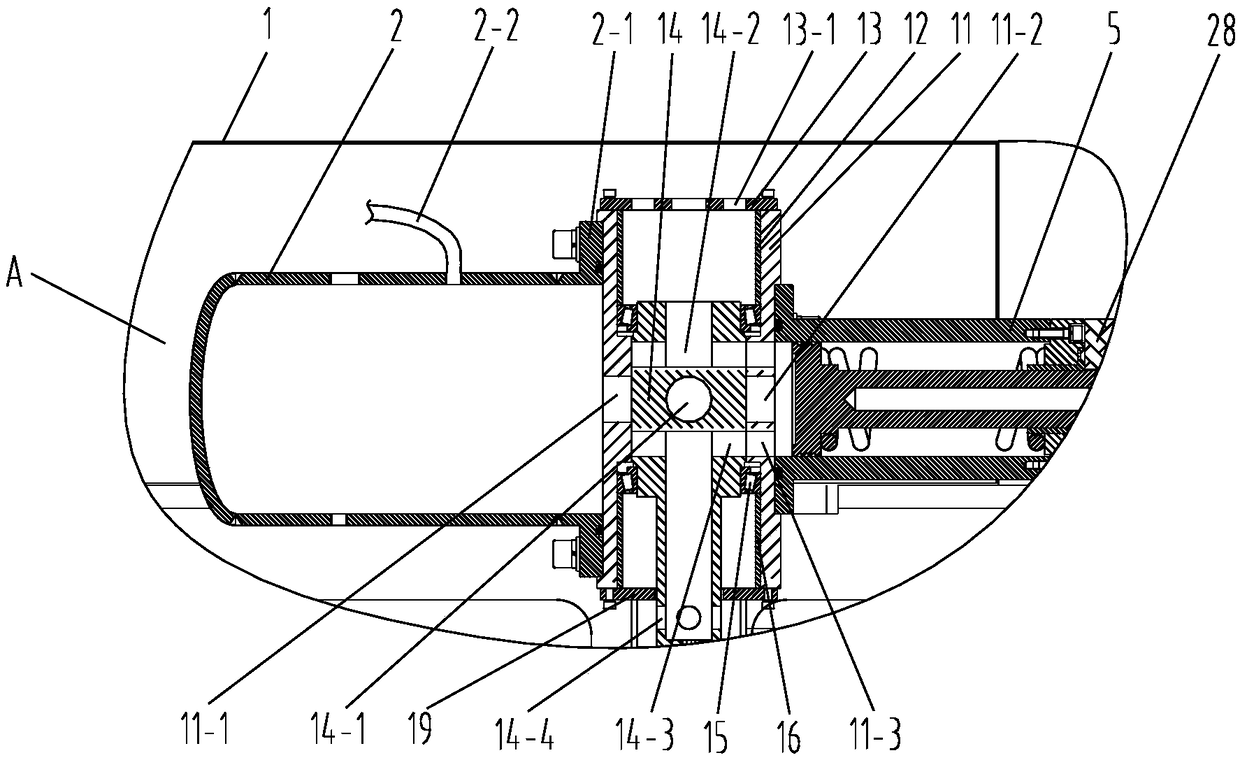

[0054] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, the horizontal continuous impact test device of the present invention includes an air reservoir 2, a bearing seat 11, a propulsion cylinder 5, a guide mechanism 6, an impact seat 8 and a base 9, and the load bearing seat 11, the guide mechanism 6 and the impact seat 8 are all installed above the base 9, the guide mechanism 6 is located between the bearing base 11 and the impact base 8, the air storage tank 2 and the propulsion cylinder 5 are relatively arranged on both sides of the bearing base 11, and the propulsion cylinder 5 is located on the bearing base Between the force base 11 and the guide mechanism 6; the force base 11 is provided with a mounting hole, and the installation hole is provided with an intake and exhaust reversing mechanism that is rotationally connected with the force base 11, and the force base 11 A servo motor 20 for driving the intake and exhaust reversing mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com