Carbon fiber multi-workstation tension control machinery automatic sample preparation method

A technology of tension control and automatic sample preparation, applied in the preparation of test samples, etc., to achieve the effects of increased data reliability, balanced sample preparation, and increased sample preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

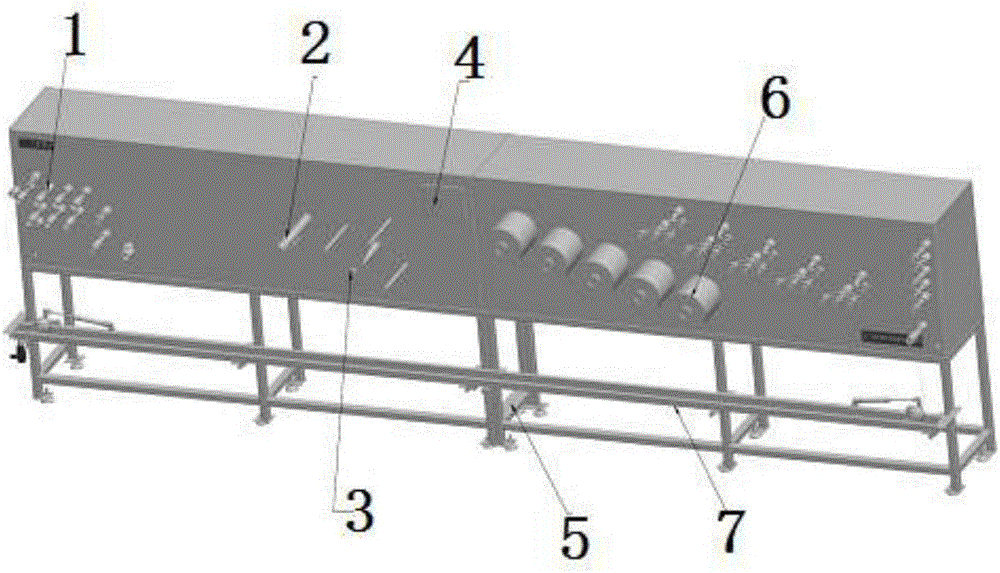

Image

Examples

Embodiment 1

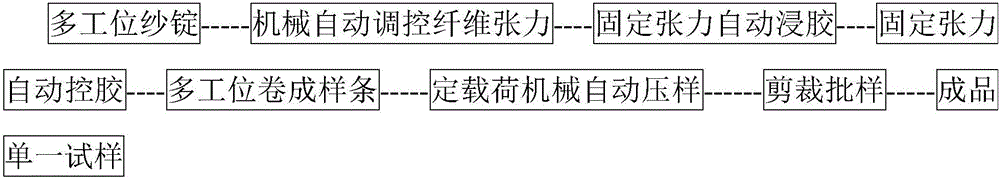

[0045] A carbon fiber multi-position tension control mechanical automatic sample preparation method, the specific steps are:

[0046] Step 1: Place 5 ingots of fiber on the spindle of the sample making machine, pass through the tensioned 5 roller guide wheels, under the set tension of 100-500 grams, pass through the resin tank at a running speed of 5m / min, and adjust the fiber Adjust the running speed of the fiber, adjust the dipping time of the fiber, squeeze out the excess resin on the fiber through the extrusion guide wheel, and several fibers are wound on a diamond-shaped sample preparation frame with stainless steel as the main body at the same time, and select the frame according to the number of sample preparation tests The number of rotations; put the frame as a whole into an oven with an inner cavity size of 1M, and dry it at the set temperature of 150°C for 2 hours; after drying, cut the test sample from the frame; this patent is the first The one-step test spline is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com