Electric leakage sensor, high-voltage distribution box and electric vehicle

A leakage sensor and voltage sampling technology, applied in electric vehicles, electric vehicle charging technology, electrochemical generators, etc., can solve problems such as false alarms, failure of leakage sensors, failure of leakage sensors to detect their own faults, etc., to achieve high safety, Guarantee the power performance and optimize the process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

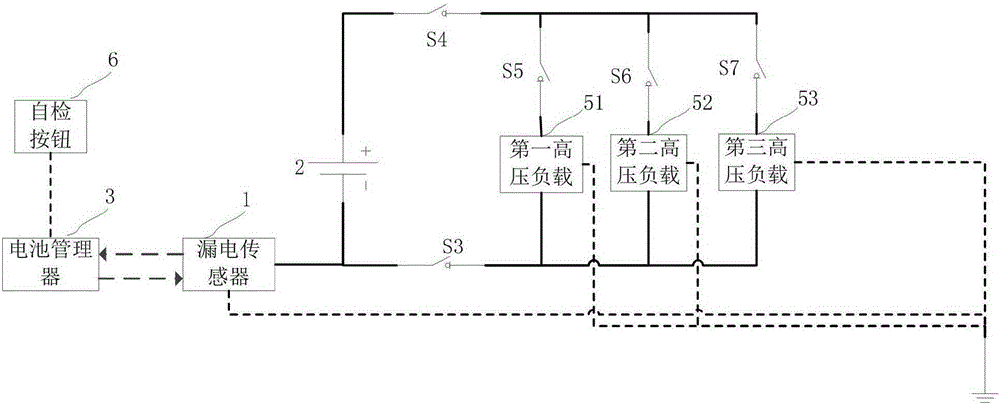

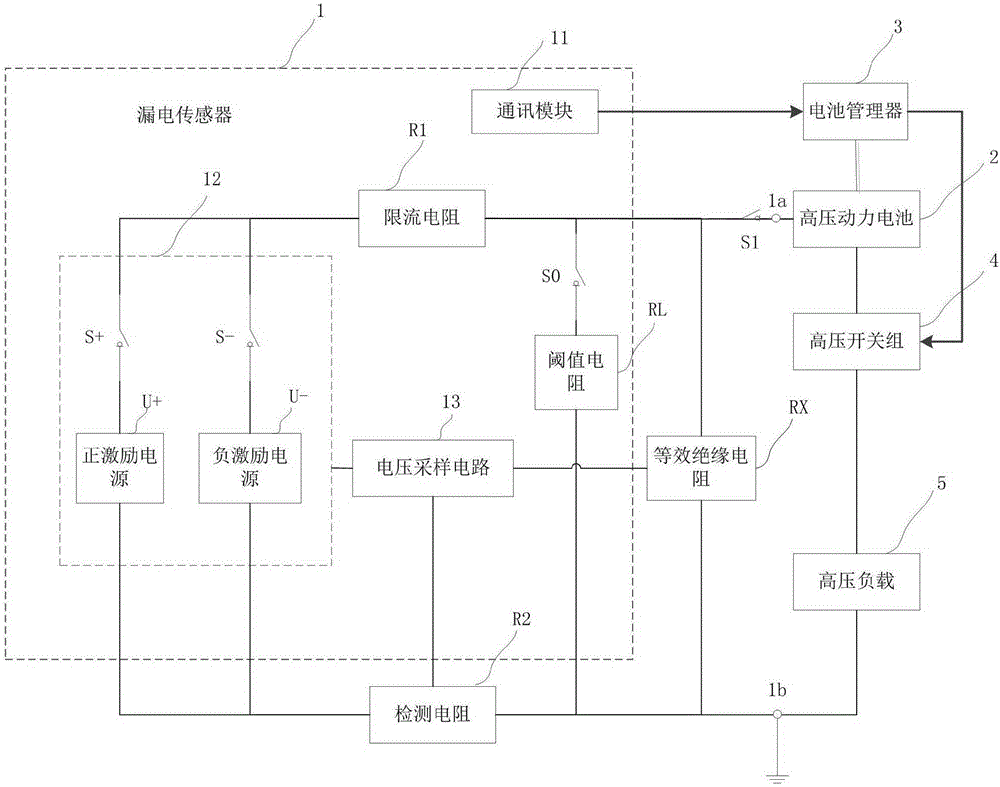

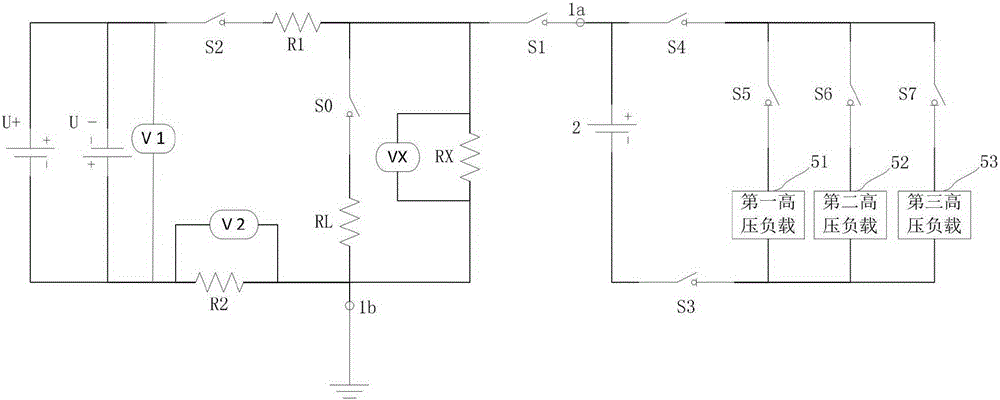

[0039] This example will specifically explain the leakage sensor 1 provided by the present invention in conjunction with the accompanying drawings, as figure 1As shown, the leakage sensor 1 in this example can be connected between any position of the high-voltage system (the high-voltage power battery 2 described in the background technology, the high-voltage load 5 and the high-voltage switch group 4) and the ground for leakage detection, so-called leakage detection It refers to the measurement and calculation of the equivalent insulation resistance RX between its high-voltage system and the insulation ground (that is, the vehicle body), and compares it with the preset threshold to determine whether it is leakage. The leakage sensor 1 in this example operates under the control of the battery manager 3 and feeds back relevant information (such as the detected voltage value or the calculated equivalent insulation resistance RX) to the battery manager 3 . In order to enable thos...

Embodiment 2

[0072] This example provides a high-voltage distribution box 100, such as Figure 4 As shown, the high-voltage distribution box 100 is provided with a high-voltage switch group 4, a high-voltage load interface 101, and a high-voltage input interface; the high-voltage switch group 4 is connected between the high-voltage load interface 101 and the high-voltage input interface;

[0073] The high-voltage distribution box 100 also includes the leakage sensor 1 provided in the above-mentioned embodiment 1; the leakage detection input terminal 1a of the leakage sensor 1 is connected to the high-voltage input interface or the high-voltage load interface 101, and the leakage sensor The ground terminal 1b of 1 is grounded.

[0074] This example does not improve other structures of the high-voltage distribution box 100, but only improves the leakage sensor 1 installed in the high-voltage distribution box 100, because the above-mentioned leakage sensor 1 and the high-voltage switch group ...

Embodiment 3

[0077] This example provides an electric vehicle, such as Figure 1-Figure 3 As shown, it includes a high-voltage power battery 2, a battery manager 3, a high-voltage load 5 and the high-voltage distribution box 100 disclosed in the above-mentioned embodiment 2;

[0078] The high-voltage power battery 2 is connected to the high-voltage input interface of the high-voltage distribution box 100 , and the high-voltage load 5 is connected to the high-voltage load interface 101 of the high-voltage distribution box 100 .

[0079] Such as figure 1 As shown, the electric vehicle also includes a self-check button 6, and the self-check button 6 is connected to the battery manager 3 through hard wires. The self-inspection button 6 is used to manually notify the battery manager 3 to send leakage self-inspection information, so as to realize manual leakage self-inspection. The user can regularly check the leakage detection function of the leakage sensor 1 on the vehicle, and only needs to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com