Reflective digital holographic microscopic imaging system and method based on pulsed laser

A digital holographic microscope and pulsed laser technology, which can be applied to instruments and other directions, can solve the problems of inability to meet dynamic capture and complex processes, and achieve the effects of easy popularization, simple steps, and increased coherence efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

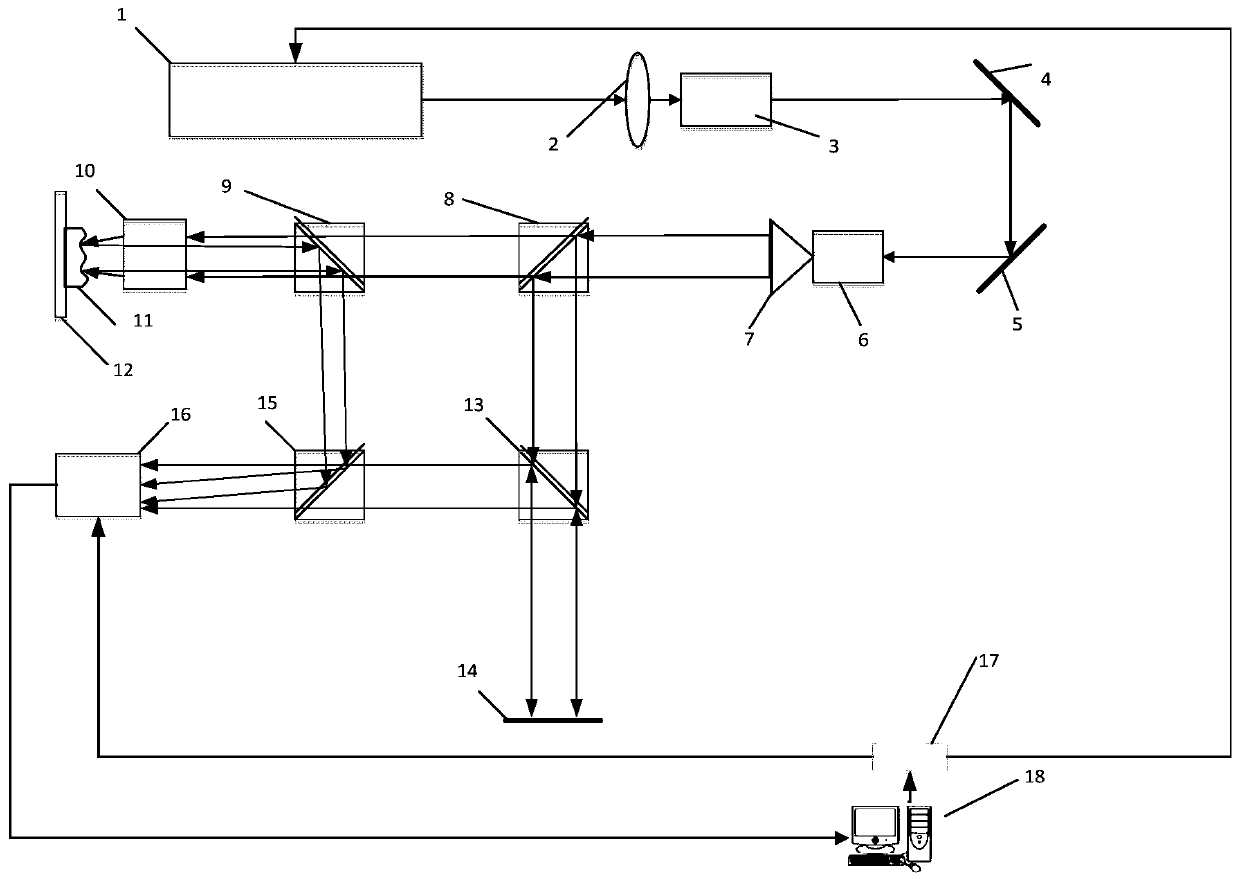

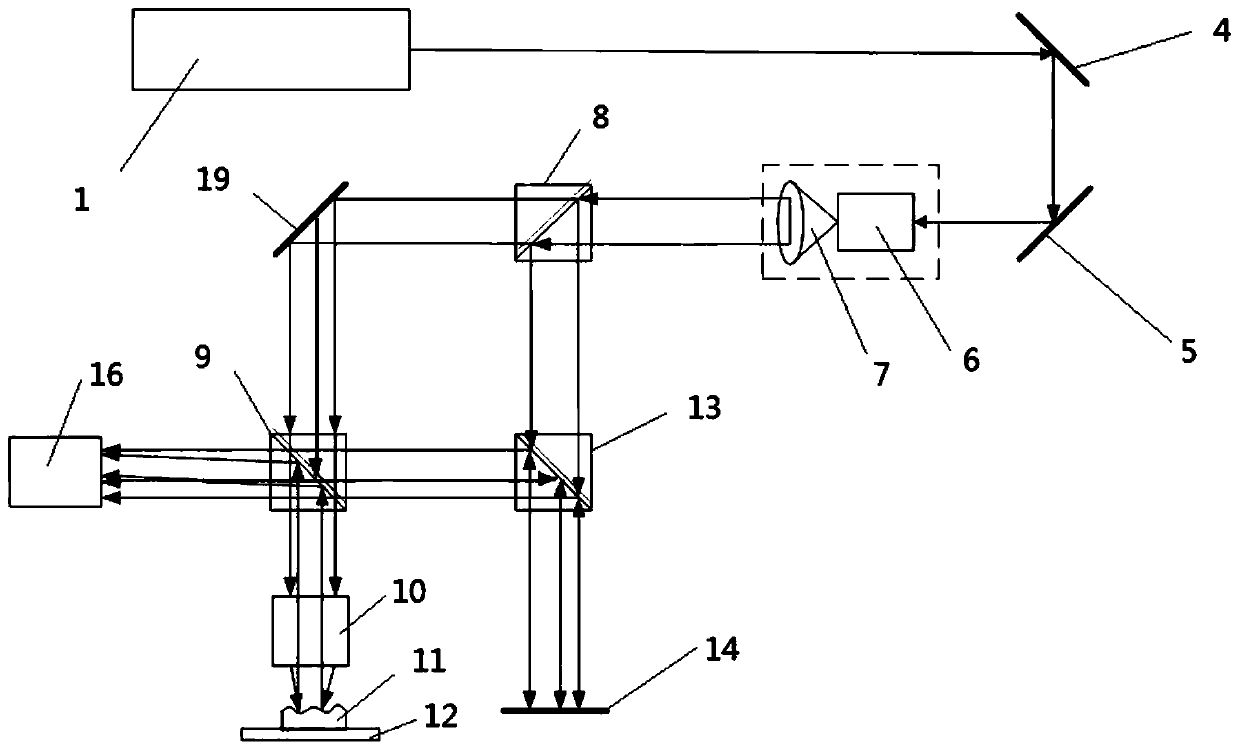

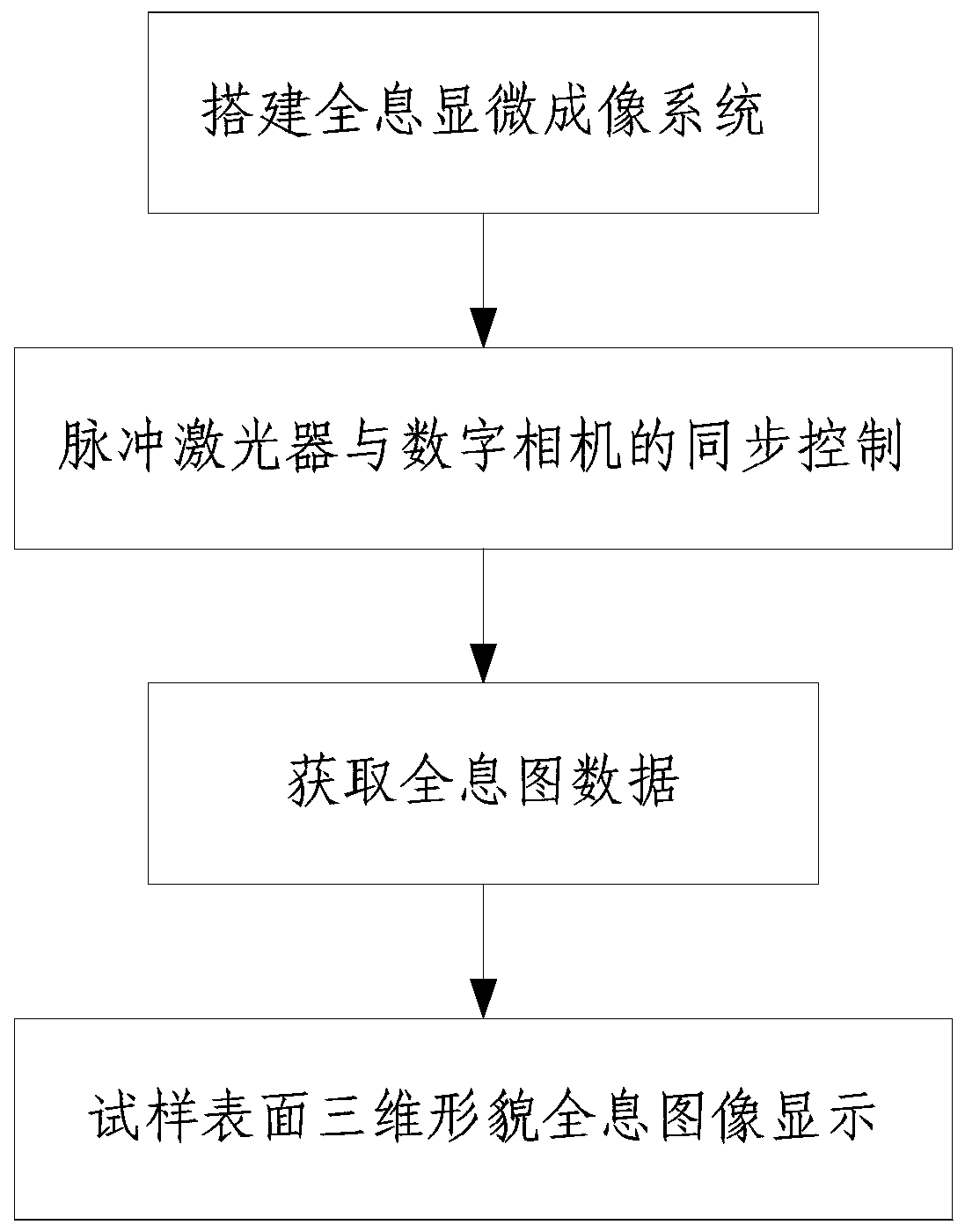

[0040] Such as figure 1As shown, the reflective digital holographic microscopic imaging system based on pulse laser according to the present invention includes an optical imaging subsystem and a synchronous control subsystem for controlling the work of the optical imaging subsystem, and the optical imaging subsystem includes A pulsed laser 1, a laser attenuator, a steering device, a beam transfer device and a holographic imaging device are arranged in sequence, and the holographic imaging device includes a first beam splitter 8, a second beam splitter arranged on the object light path of the first beam splitter 8 The beam splitter 9 and the third beam splitter 13 arranged on the reference light path of the first beam splitter 8, the object light passes through the second beam splitter 9 and the microscope objective lens 10 and irradiates the solid sample 11 with high-frequency micro-vibration Above, the sample 11 is installed on the sample fixing table 12, the reference light ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com