Brushing machine of inner tube air valve

A technology of air nozzle and slurry brushing, which is applied in the direction of coating, liquid coating device on the surface, etc., which can solve problems such as uneven glue coating, increased scrap rate, and affecting the quality of inner tube semi-finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

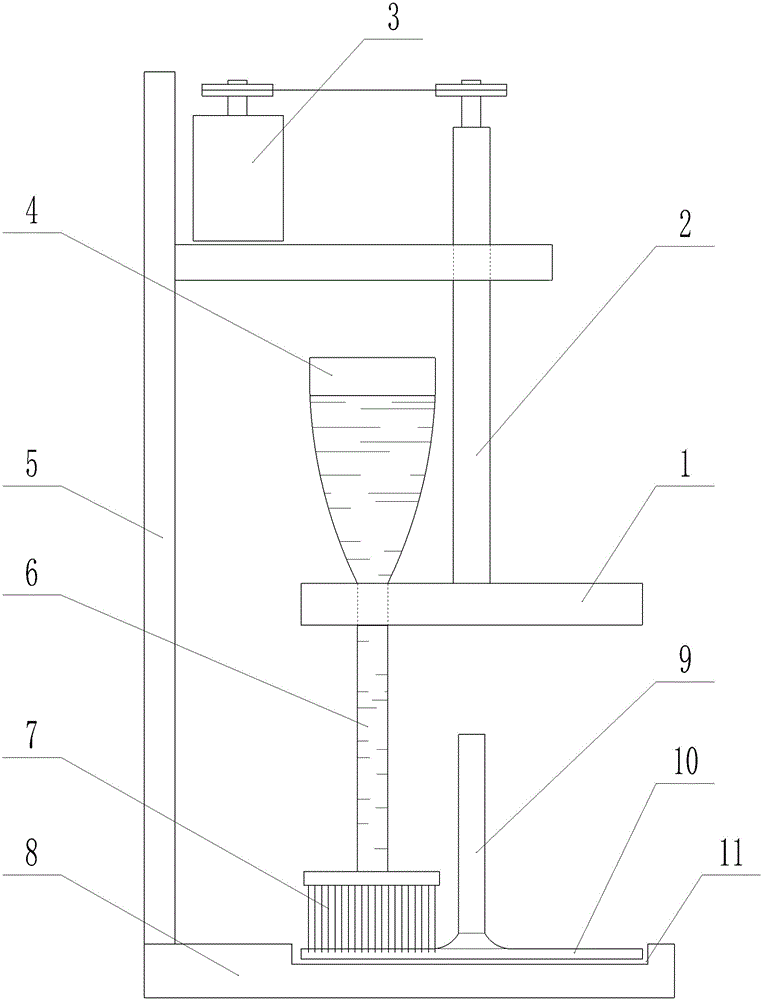

[0012] refer to figure 1 , including a base 8, a frame 5, a motor 3, a brush 7 and a turntable 1, the frame 5 is arranged on the base 8, the center of the turntable 1 is connected to the rotating shaft 2, and the turntable 1 is provided with a container for loading glue 4. The container 4 communicates with the conduit 6 passing through the turntable 1 , the lower end of the conduit 6 communicates with the brush 7 , and the rotating shaft 2 is connected with the motor 3 .

[0013] The base 8 is provided with a groove 11 for placing and stabilizing the rubber body 10 of the brushed air nozzle 9 .

[0014] After starting the motor 3, the motor 3 drives the turntable 1 to rotate through the rotating shaft 2, and the turntable 1 drives the brush 7 to rotate, and the glue in the container 4 of the glue flows into the brush 7 through the conduit 6, and the brush 7 rotates to apply the glue evenly on the On the rubber body 10 of the inner tube air nozzle 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com