Tire wire automatic welding machine for manufacturing high-performance steel shots

An automatic welding machine, high-performance technology, applied in the field of automatic machinery, can solve problems such as difficult quality assurance, poor uniformity and consistency, poor geometry, etc., to achieve the effect of convenient replacement and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

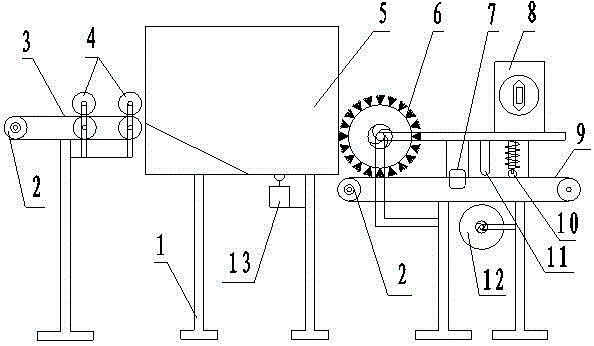

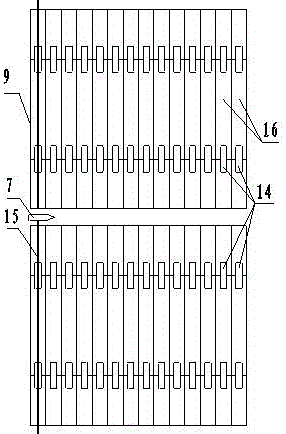

[0017] in such as Figure 1~2 In the shown embodiment, a tire steel wire automatic welding and heat treatment machine for preparing high-performance steel shot consists of a frame 1, a drum motor 2, a conveyor belt 3, a squeeze roller 4, a cloth distributor 5, a cloth brush 6, an initial The positioning mechanism 7, the chain material plate 9, the position sensor 11, the contact mechanism 10 and the control system are composed. When working, the organized tire steel wire 15 is placed on the conveyor belt 3 by the electromagnetic absorber. According to the working efficiency of the rear Determine the amount of adsorption, the roller motor 2 is set on the frame 1, the conveyor belt 3 is wound on the outer circular surface of the roller motor 2, the roller motor 2 drives the conveyor belt 3 to rotate, the tire steel wire 15 follows the conveyor belt 3, squeezes The rollers 4 are fixed on the frame 1, the extrusion rollers 4 appear in pairs, the conveyor belt 3 is located between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com