Rapid high-precision normal vector measurement method for hole making point of complicated curved surface

A technology of complex surface and measurement method, which is applied in the field of vector measurement of complex surface hole-making point method, and can solve the problems of low efficiency and low vector measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

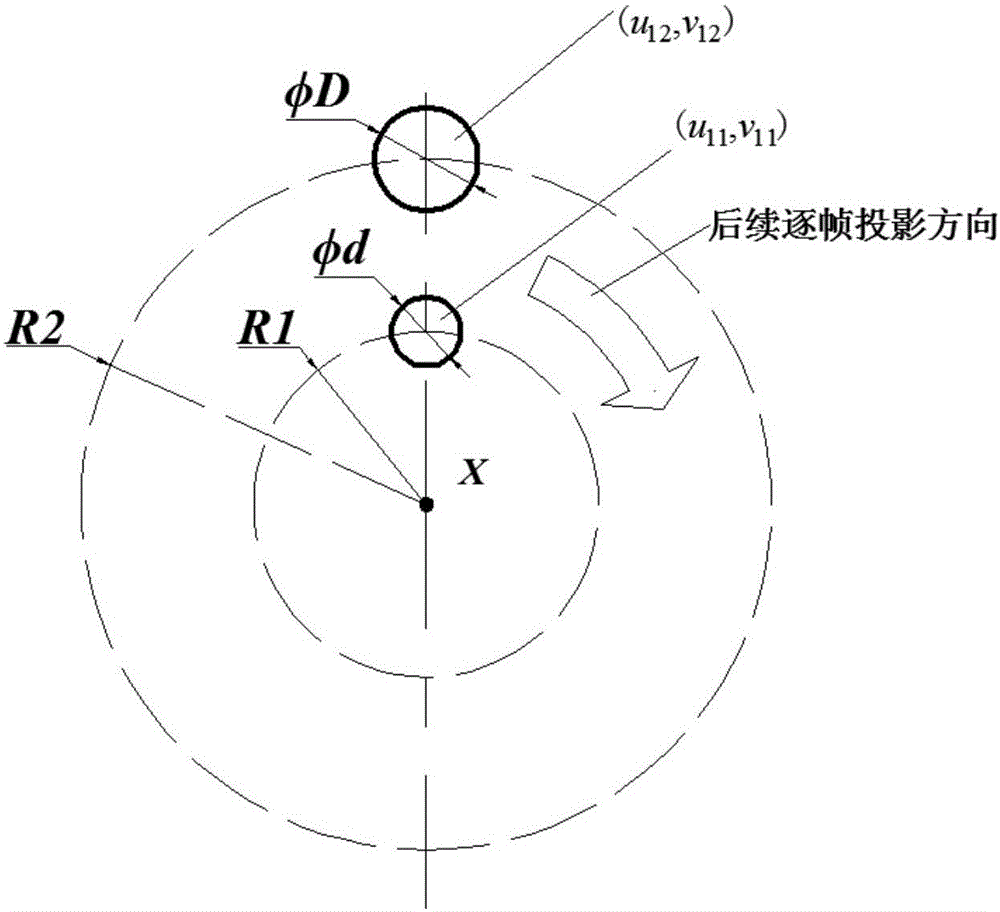

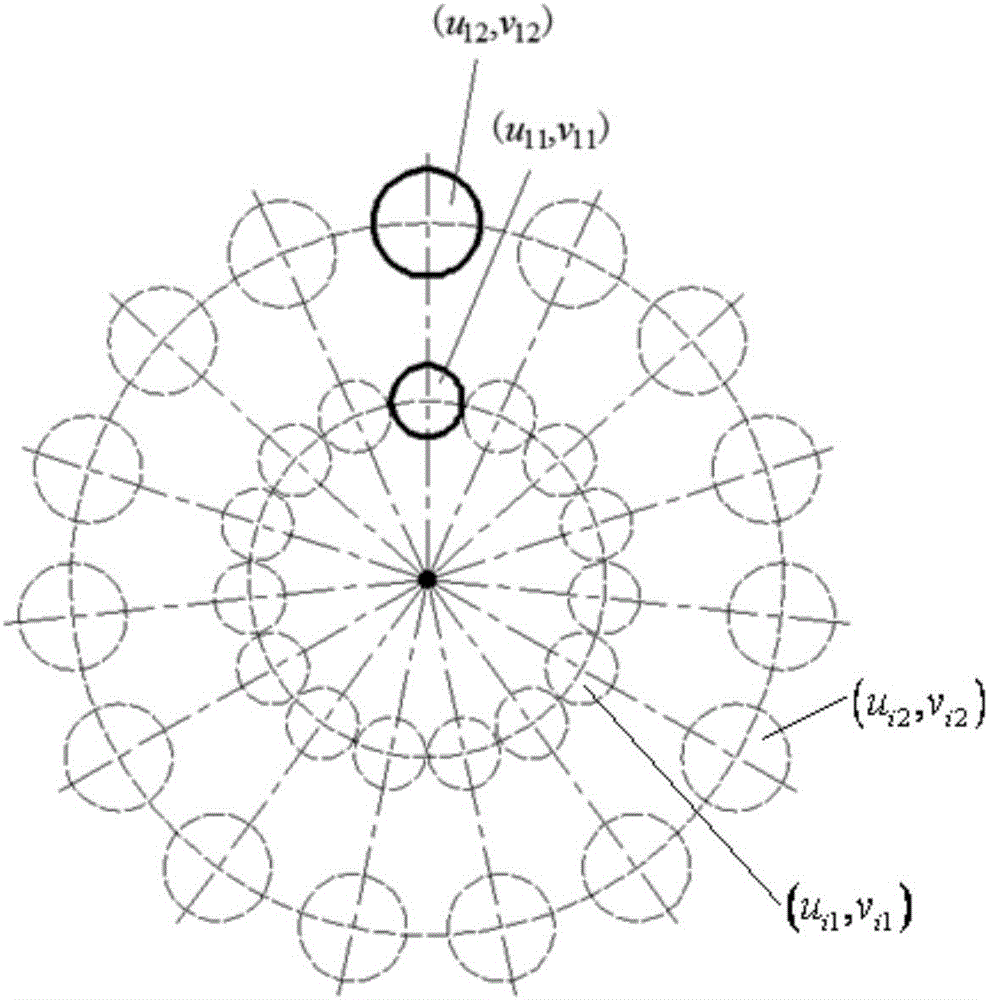

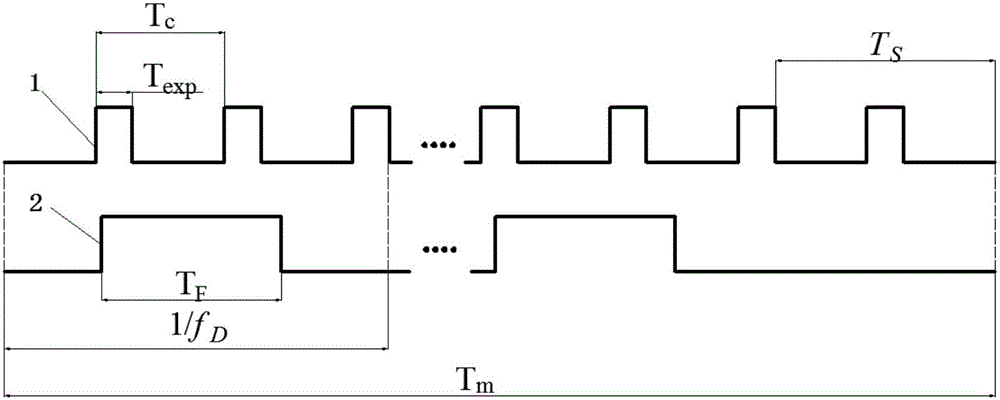

[0062] In this embodiment, the surface of the object to be measured is a 3.4m×0.6m t800 composite material plate, and each group of dynamic projection points is projected onto the composite material plate at a certain angle in chronological order, as shown in the attached figure 1 , 2 As shown, adjust the focal length of the camera to collect a clear image of the projection point, and control the camera acquisition time to match the projection point, as shown in the attached image 3 shown.

[0063] The present invention adopts left and right cameras respectively equipped with wide-angle lenses to shoot a plurality of projection point images. The camera model is view works VC-12MC-M / C 65 camera, resolution: 4096×3072, image sensor: CMOS, frame rate: full frame, maximum 64.3fps, weight: 420g. The wide-angle lens m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com