Air suction and exhaust system structure of piston type refrigeration compressor

A refrigeration compressor and system structure technology, applied in the direction of liquid variable volume machinery, mechanical equipment, variable volume pump components, etc., can solve the problems of impact fatigue, bending fatigue damage, etc., to reduce suction overheating, reduce exhaust gas Pressure pulsation, the effect of improving thermodynamic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

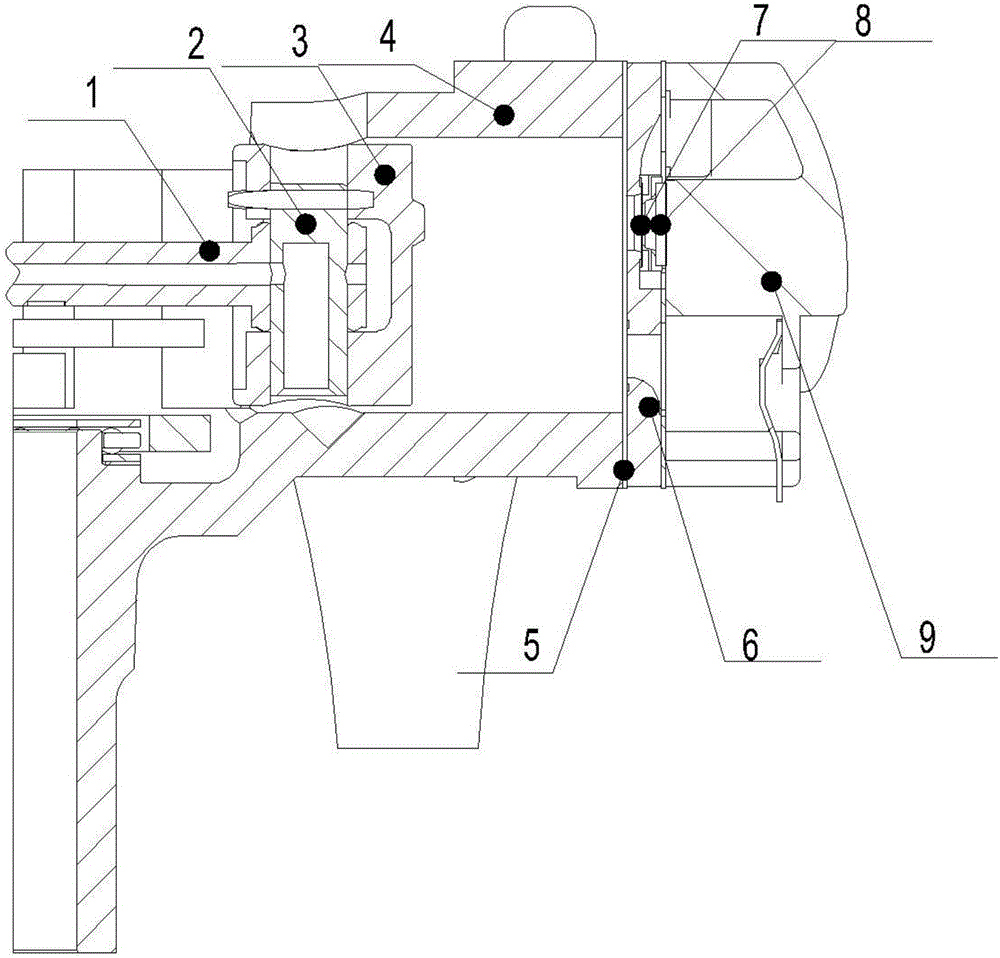

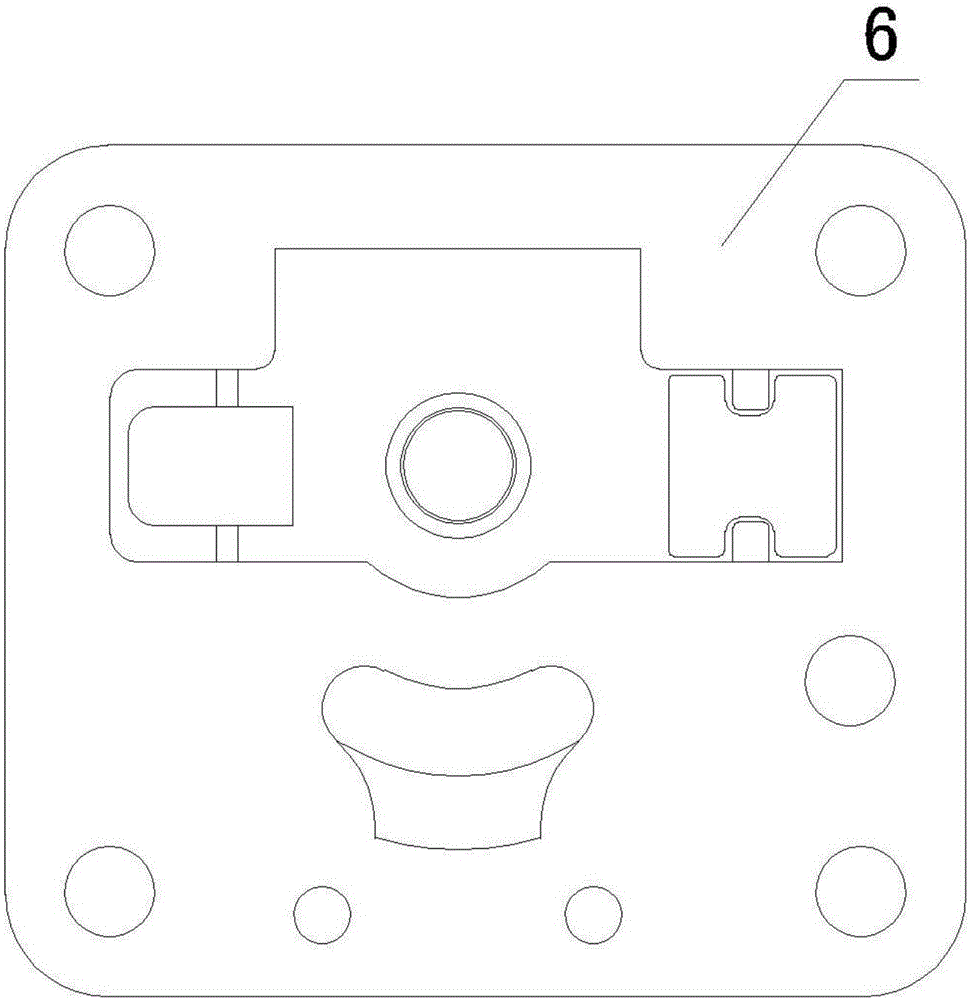

[0016] Such as Figure 4 As shown, the structure of the suction and exhaust system of the present invention includes a connecting rod 1, a piston pin 2, a piston 3, a crankcase 4, a valve plate 6, an exhaust valve plate 7, an exhaust limiter 8 and a cylinder head 9. One end of the connecting rod 1 is connected with the piston 3 through the piston pin 2, the piston 3 is arranged in the crankcase 4, and the exhaust valve plate 7 and the exhaust limiter 8 are arranged on the valve plate 6.

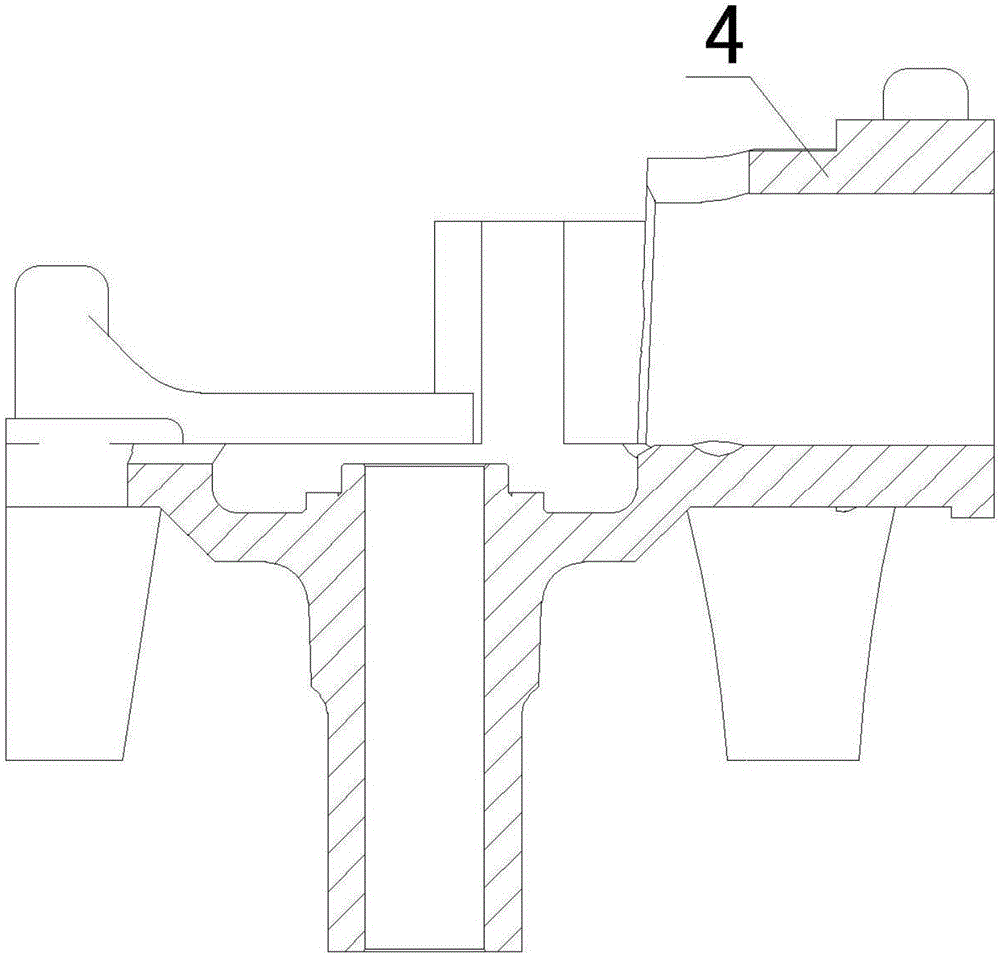

[0017] Please also see Figure 5 Shown, the cylinder hole 13 wall surface of crankcase 4 has offered suction hole 10. The distance a (in mm) between the opening position of the suction hole 10 and the crankcase end surface 12 is greater than 1 / 3 of the piston stroke and less than 1 / 2 of the piston stroke. This distance setting can maximize the cylinder utilization rate of the compressor, and at the same time ensure that the compressor consumes less power during the suction process (if the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com