Electronic nose technology-based method for rapidly predicating fat oxidation degree of meat and meat products

A fat oxidation and electronic nose technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of cumbersome operation, poor reliability of measurement results, and easy drift of sensor baselines, and achieve simple and fast non-contact online monitoring of sample processing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

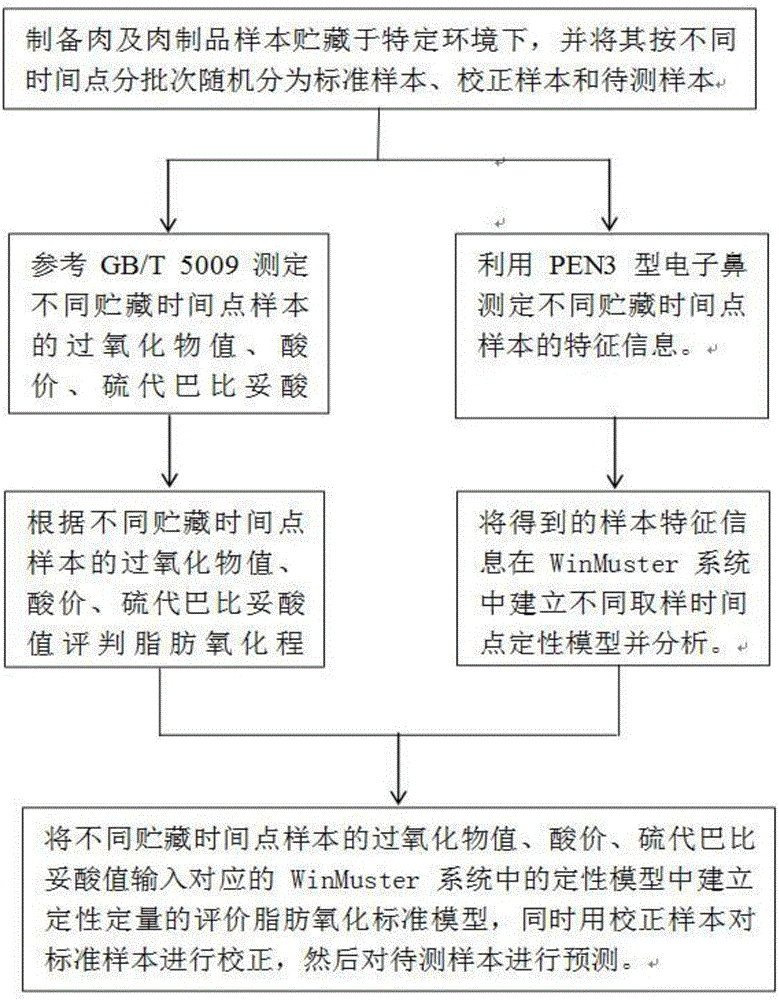

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Evaluation method for rapidly predicting the degree of fat oxidation in the back (abdomen) of grass carp based on electronic nose technology

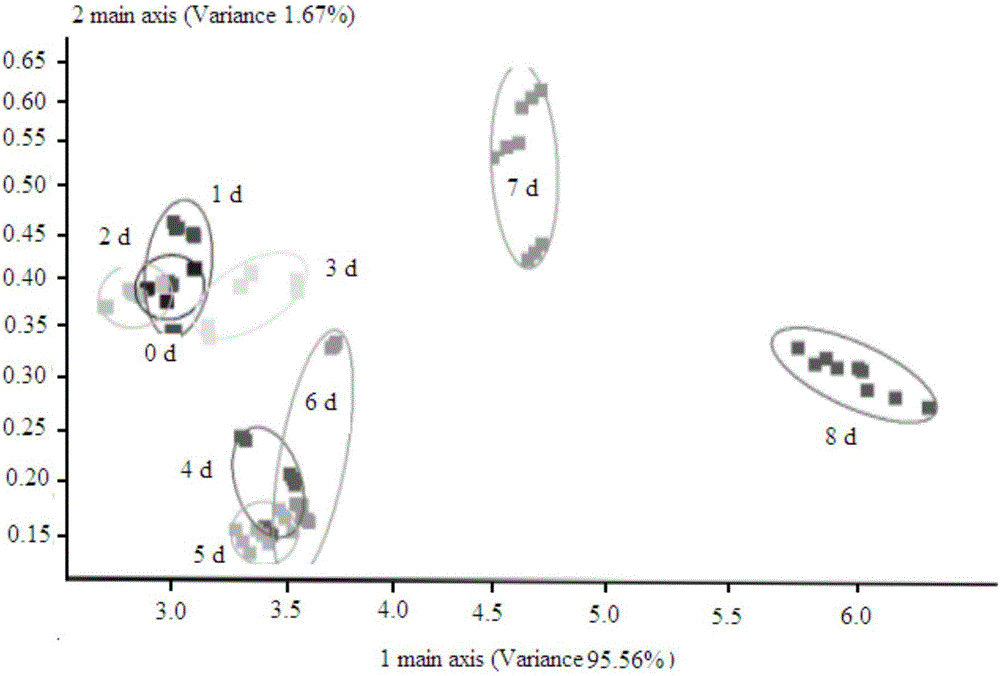

[0029]Remove the scales, viscera, head, tail and skin of the slaughtered grass carp, rinse it with running water, absorb the residual water on the surface of the fish with absorbent paper, separate the back (abdomen) part, and weigh 10.00g ( Accurate to 0.01g) Make standard samples and calibration samples of back and abdomen meat samples. , 5, 6, 7, and 8 days, prepare and store the samples of the back (abdomen) of the fish to be tested under the condition of 4° C. for future use. Regularly randomly select standard samples and calibration samples, weigh a certain amount of back and abdomen meat samples, determine acid value (AV) according to GB / T 5009.37-2003, and determine thiobarbituric acid according to GB / T5009.181-2003 According to GB5009.227-2016, measure peroxide value (POV), and then use PEN 3 electronic nose t...

Embodiment 2

[0030] Example 2 Evaluation method for rapidly predicting the degree of fat oxidation in Cantonese-style sausage processing based on electronic nose technology

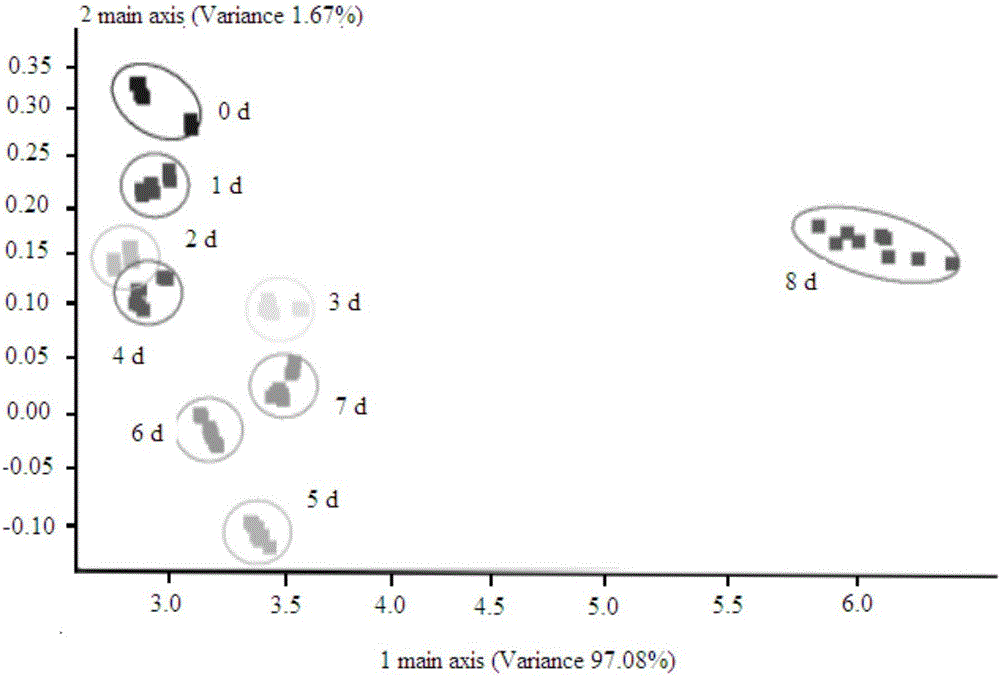

[0031] Grind the cleaned and screened pork into diced meat through a 5mm meat grinder, mix according to a certain proportion of ingredients, stir well, and marinate at 4°C for 1 hour, then add it to the sausage enema machine, pour it into warm water and soak it for 30 minutes And washed pig small intestine casing. After filling the sausages, prick the holes with fine needles every 1.5cm to release air, rinse the sectioned sausages in warm water at 35°C, drain them, and hang them in a constant temperature and humidity box (temperature: 60°C, humidity: 40%) Baking 0h, 12h, 24h, 36h, 48h, 60h, 72h, weighing 10.00g (accurate to 0.01g) respectively to make standard samples and calibration samples in the process of Cantonese-style sausage processing, each sample capacity is 50, and Prepare the samples to be tested in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com