Armored cable

An armored optical cable and optical fiber technology, applied in the field of armored optical cable, can solve the problems of loss of communication function, failure to guarantee the service life of optical cable, delay in obtaining real-time information, etc., to avoid compression damage, good tensile strain capacity, and buffering effect. maximized effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

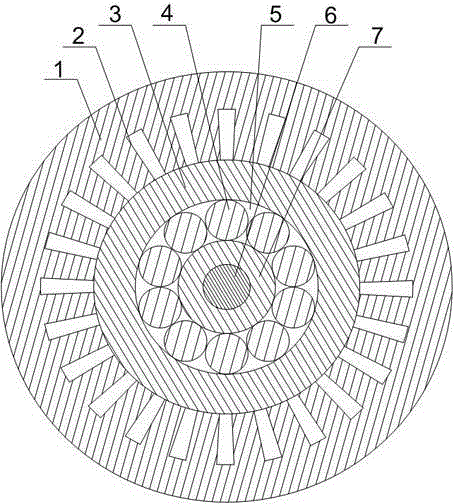

[0020] Such as figure 1 As shown, this embodiment includes a casing 3, and a polyurethane sheath 1 is sheathed on the outer wall of the casing 3, and a plurality of buffer grooves 2 are opened on the inner wall of the polyurethane sheath 1 along its axial direction, so that The width of the buffer groove 2 increases outward along the radial direction of the polyurethane sheath 1, and a plurality of optical fibers 4 are arranged inside the sleeve 3, and the plurality of optical fibers 4 are helically twisted in the middle of the sleeve 3. On the aramid fiber tube 7, and between the sleeve 3 and the aramid fiber tube 7 is filled with fiber paste 5; FRP reinforcement 6 is also included, and the FRP reinforcement 6 is arranged in the aramid fiber tube 7 .

[0021] During production and manufacture of the present invention, a plurality of optical fibers 4 are twisted in a helical shape on the aramid limiting tube with strong tensile strain capacity, and then the composite structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com