Method for manufacturing substrate seedling-growing floating tray

A manufacturing method and a matrix seedling raising technology are applied in the manufacturing field of matrix seedling raising floating trays, which can solve the problems of increasing cost and the like, and achieve the effects of simple method and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

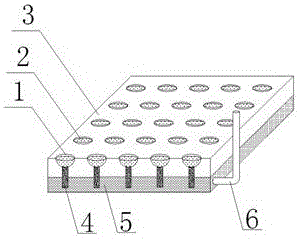

[0023] The present invention will be described below in conjunction with the accompanying drawings.

[0024] The manufacturing method of the substrate seedling raising floating tray of the present invention, wherein, comprises the following steps:

[0025] A. A water box is installed at the bottom of the fertilizer tray, and a sponge layer is installed in the water box, and the upper insulation layer, the lower water box and the sponge layer in the water box are integrally pressed and formed;

[0026] B. Open a number of holes in the insulation layer, and install fertilizers in the holes;

[0027] C. Insert and connect the water inlet pipe on one side of the water box, and pour water along the water inlet pipe until the sponge layer is fully absorbed. D. The outer wall of the insulation layer is integrally formed with a black light-absorbing paint layer.

[0028] The matrix seedling raising floating plate that the manufacturing method of the present invention makes is such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com