Spray drying tower

A technology of spray drying tower and drying tower, applied in the direction of spray evaporation, evaporator accessories, etc., can solve the problems affecting the drying effect and drying efficiency of materials, and achieve the effects of improving drying effect and drying efficiency, improving dust removal function, and increasing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below in conjunction with specific embodiment, further set forth the present invention:

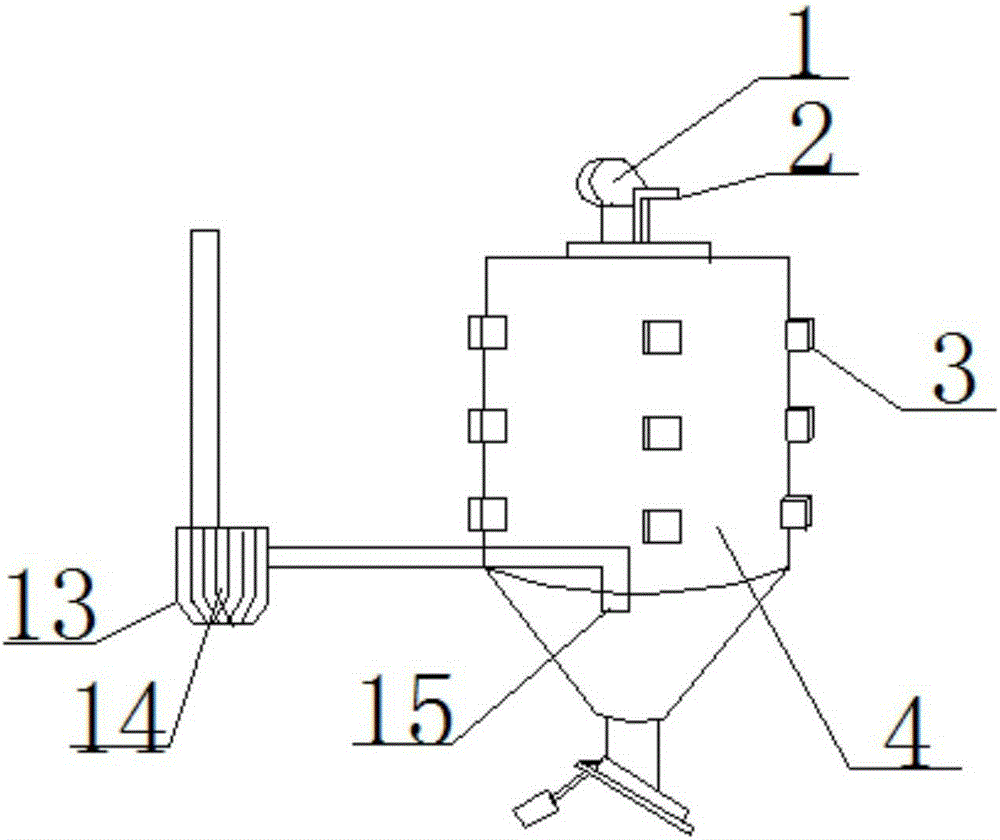

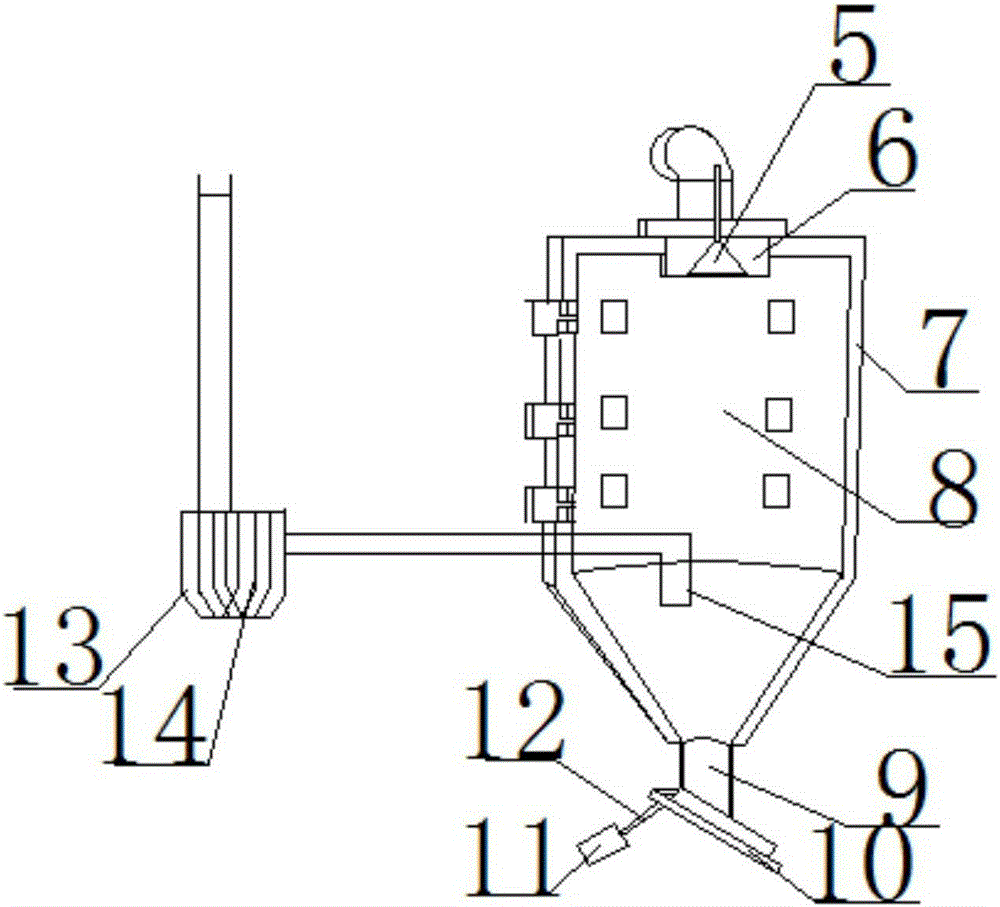

[0012] like figure 1 , 2 As shown, the present invention includes a drying gas pipe 1, a material pipe 2, a drying tower body 4, a nozzle 5, a drying gas inlet 6, a tower wall 7, an inner cavity 8 and a material outlet 9, a drying gas inlet 6, a drying gas pipe 1 and a material The pipes 2 are all arranged on the top of the drying tower body 4, and the end of the material pipe 2 is equipped with a nozzle 5; the discharge port 9 is obliquely arranged below the drying tower body 4, and the spray drying tower is also provided with a water atomization pipe 14, a water atomization pipe 14 There are four layers, the water atomization pipe 14 is provided with a suction pipe mouth 15, and a dust collector 13 is arranged between the water atomization pipe 14 and the suction pipe mouth 15. After water vapor and a small amount of fine powder are discharged to the dust collector 13 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com