Vehicle roof outer plate punching device

A punching and plate punching technology is applied in the field of punching devices for roof outer panels, which can solve the problems of increased production cost of the roof panel, influence of the production efficiency of the roof panel, non-compliance with the requirements of versatility, etc., and achieves convenient maintenance and replacement. , the effect of improving service life and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

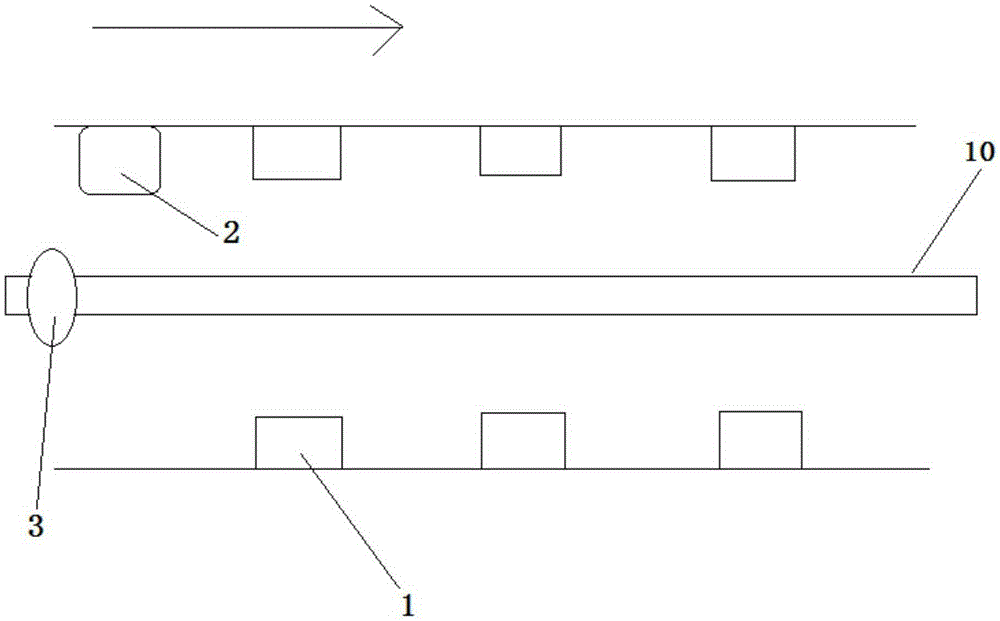

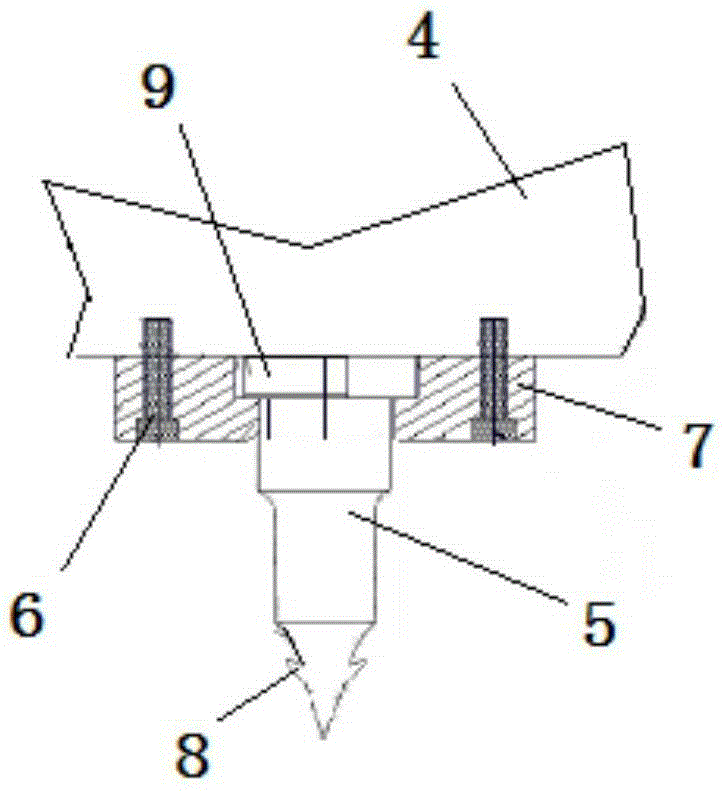

[0023] A kind of roof outer plate punching device, its structure is as follows figure 1 As shown, it is used to punch the roof outer panel with sunroof and the roof outer panel without sunroof fixed on the conveyor. The punching device includes two sets of punching mechanisms arranged on both sides of the conveyor: matching belt The first punching mechanism for the roof outer panel with the sunroof and the second punching mechanism for the roof outer panel without the sunroof, and the sensor 3, which is installed above the conveyor and detects the roof outer panel model entering the punching device, punches Both the mechanism and the sensor 3 are connected to the PLC control system. The first punching mechanism includes six first punching units 1 arranged on both sides of the conveying device, and the second punching unit 2 includes a second punching unit 2 and six punching units. The first punching unit 1, the second punching unit 2 is arranged between the first punching unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com