Applications of organosilanes, polyolefin resin and preparing method of the polyolefin resin

A polyolefin resin and organosilane technology, which is applied in the field of polyolefin resin and polyolefin resin preparation, can solve the problems of low melt strength of polyolefin resin and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

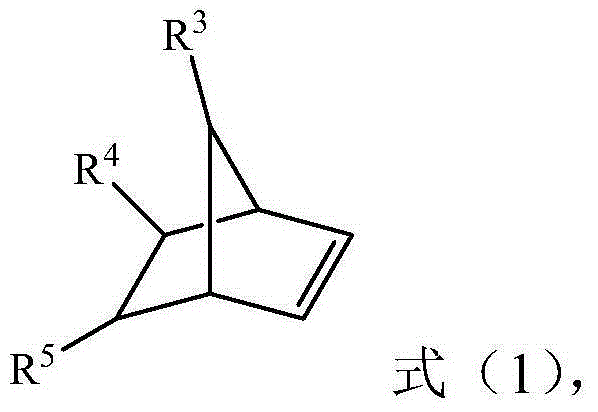

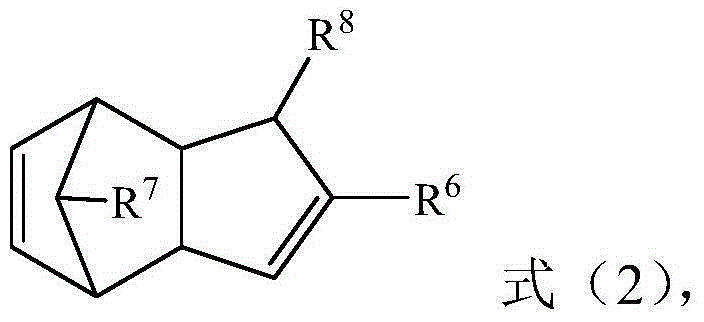

[0023] The preparation method of the polyolefin resin provided by the present invention comprises carrying out the olefin polymerization reaction of the olefin monomer in the presence of a catalyst, wherein, the method also includes adding the olefin monomer before and / or during the olefin polymerization reaction In the polymerization reaction system, organosilane is added, and the general formula of the organosilane is R 1 m SiX n (OR 2 ) k , where R 1 for C 2 -C 20 Hydrocarbyl and R 1 The end contains α-olefin double bond, norbornene group, cycloalkene group or dicyclopentadiene group, X is halogen, R 2 for C 1 -C 20 straight chain, branched or isomerized alkyl, m is an integer of 1-3, n is an integer of 1-3, k is an integer of 0-2, and m+n+k=4.

[0024] In addition, the specific selection of the organosilane has been described above and will not be repeated here.

[0025] The amount of the organosilane used in the present invention is not particularly limited, pr...

Embodiment 1

[0038] This example is used to illustrate the preparation method of the polyolefin resin provided by the present invention.

[0039] Slurry polymerization: under vacuum, 450 g of gaseous propylene monomer was charged into the reactor, and then 50 mL of hexane, 3 mL of heptane solution containing 5.5 mmol of triethylaluminum, 7-octenyl trichloro Silane 0.1 mL and 20 mg olefin polymerization catalyst (MgCl 2 / TiCl 4 / BMMF, where BMMF is the internal electron donor 9,9-dimethoxyfluorene, MgCl 2 、TiCl 4 The mass ratio to BMMF is 80:12:8), and the pressure in the reactor is controlled at 5.0 atmospheres, the reaction temperature is controlled at 60°C, and the polymerization is carried out for 0.5 hours. After the polymerization is completed, acidified ethanol is added to terminate the polymerization, and then respectively Wash with deionized water at a temperature of 60° C. and ethanol at a temperature of 50° C. each for three times, and finally vacuum-dry at 60° C. to obtain 20...

Embodiment 2

[0041] This example is used to illustrate the preparation method of the polyolefin resin provided by the present invention.

[0042] Bulk polymerization: under vacuum, 450 grams of liquid propylene was added to the reactor, followed by 0.25 mol of triethylaluminum, 0.005 gram of hydrogen, 0.02 mL of 7-octenyl trichlorosilane and 18 mg of olefin polymerization catalyst (MgCl 2 / TiCl 4 / BMMF, where MgCl 2 、TiCl 4The mass ratio to BMMF is 80:12:8), the reaction temperature is controlled at 70°C, and the polymerization is carried out for 30 minutes. Washing was performed, and vacuum drying was performed at 60° C. to obtain a homopolymer polypropylene resin. After testing, the concentration of 7-octenyltrichlorosilane in the homopolypropylene resin is 57ppm, the homopolypropylene resin has a branched or crosslinked structure, and its gel content is 1.1% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com