Pure acrylic emulsion with excellent freeze-thaw stability and preparation method for pure acrylic emulsion

A freeze-thaw stability, pure acrylic emulsion technology, applied in the field of organic polymer materials, can solve the problems of film-forming performance decline at room temperature, atmospheric environmental pollution, and calcium ion stability, and achieve excellent freeze-thaw stability and expand The effect of application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

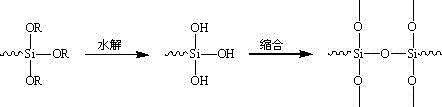

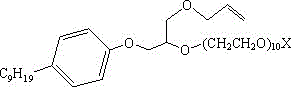

Method used

Image

Examples

Embodiment Construction

[0050] The technical solutions of the present invention will be described in detail below through specific embodiments. Unless otherwise specified, the raw materials used in the embodiments are commercially available industrial products, and the dosages are all parts by weight.

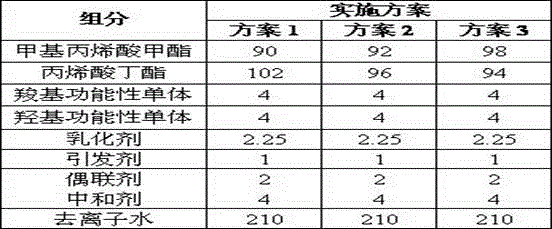

[0051] 1. A pure acrylic emulsion of excellent freeze-thaw stability, the component weight ratio of its formula is prepared according to the embodiment of table 1:

[0052] Table 1

[0053]

[0054] The preparation method of above-mentioned a kind of excellent freeze-thaw stability pure acrylic emulsion is the same, comprises the following steps:

[0055] (1) First put part of the emulsifier and an appropriate amount of deionized water in the stirring tank, start stirring at a stirring speed of 200~300r / min to dissolve the emulsifier, and mix all the mixed monomers (methyl methacrylate, butyl acrylate , carboxyl functional monomer, hydroxyl functional monomer mixture) into the stirring tank withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com