Rubber composition of tire tread and application of rubber composition

A technology for a rubber composition and a tire tread, which is applied in the field of rubber compositions for tire treads, can solve the problems that the dynamic ozone aging protection effect cannot be achieved, the performance and ozone aging protection are difficult to achieve, and the anti-aging agent is not contained. Good aging protection effect, good ozone aging performance, excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

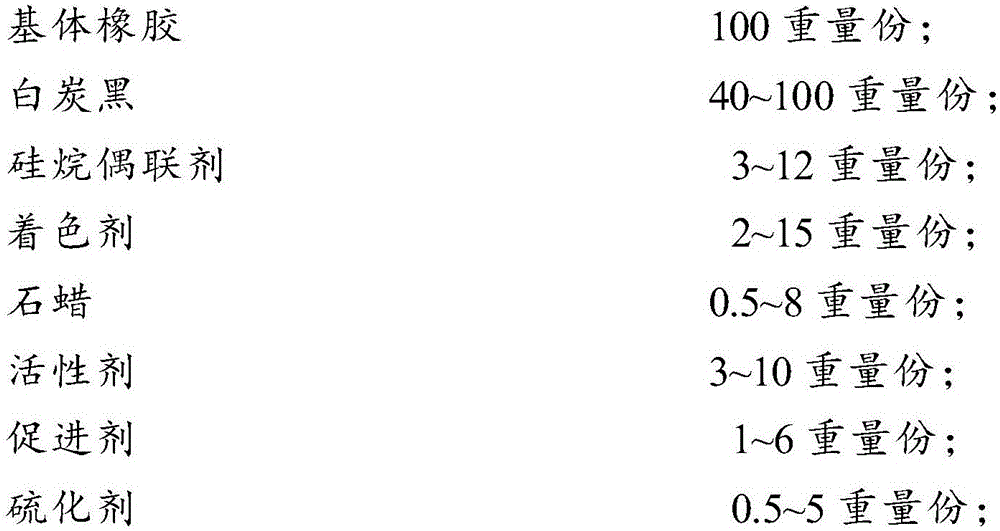

Method used

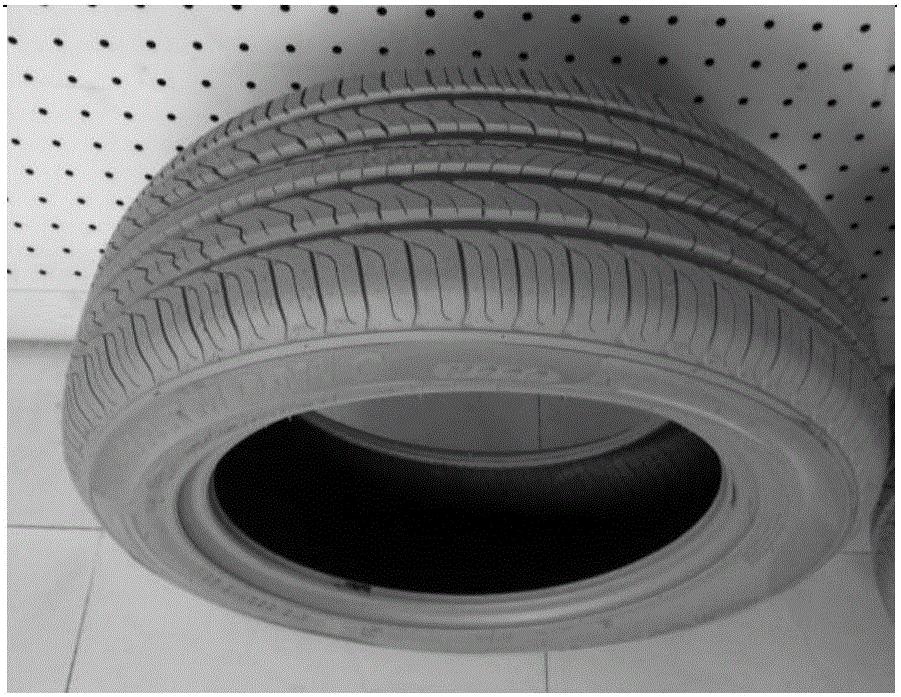

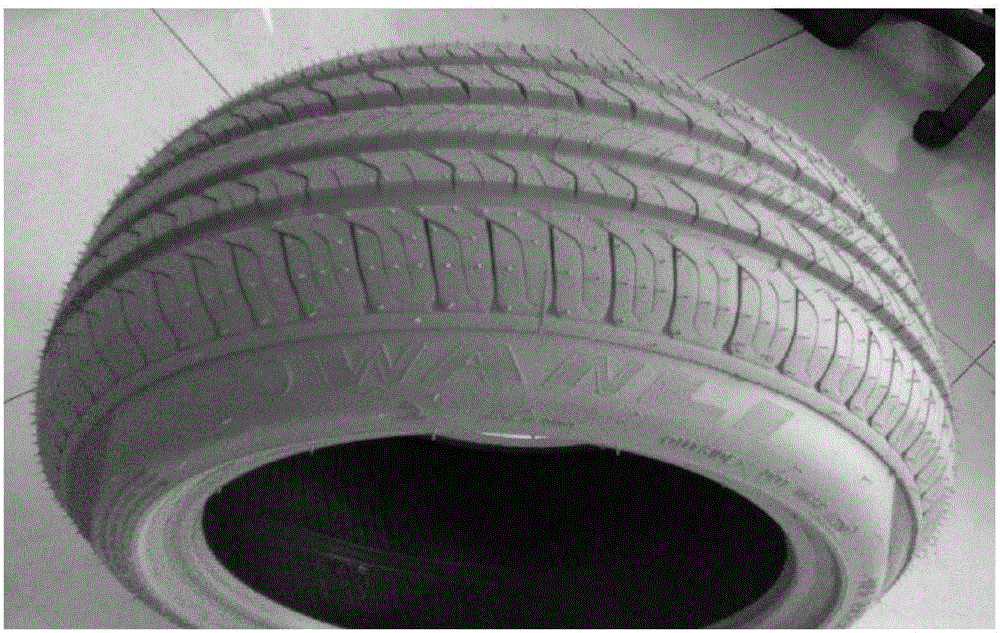

Image

Examples

Embodiment 1

[0041] In parts by weight, the components are: natural rubber 60, bromobutyl rubber 40, white carbon black 50, silane coupling agent 5, red dye 8, titanium dioxide 10, naphthenic oil 10, paraffin wax 1.5, active agent 6 , Accelerator 2.7, vulcanizing agent 1.6, dispersant 3.5; mixed with the above formula to prepare a red rubber compound. The rubber compound performance test results are shown in Table 1.

Embodiment 2

[0043] In parts by weight, the components are: oil-extended soluble polystyrene-butadiene (including 15 parts of naphthenic oil) 75, bromobutyl rubber 40, white carbon black 60, silane coupling agent 5.5, blue dye 6, titanium White powder 10, naphthenic oil 5, paraffin 1.5, active agent 6, accelerator 2.5, vulcanizing agent 1.6, dispersant 7; blue rubber compound was prepared with the above formula, and the rubber compound performance test results are shown in Table 1.

Embodiment 3

[0045] In parts by weight, the components are: natural rubber 60, bromobutyl rubber 30, EPDM rubber 10, white carbon black 50, silane coupling agent 5, blue dye 6, titanium dioxide 30, naphthenic oil 10. Paraffin wax 1.5, active agent 6, accelerator 2.5, vulcanizing agent 1.6, tackifying resin 4, dispersant 3; blue rubber was prepared with the above formula, and the rubber performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com