Camellia seed oil winterization method and device

A technology for camellia oleifera seed oil and camellia oleifera, which is applied in the field of camellia oleifera seed oil production, can solve the problems of low yield, unevenness and fullness, and short shelf life of camellia oleifera seed oil, and achieves the effects of high yield, uniform and sufficient precipitation, and extended shelf life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

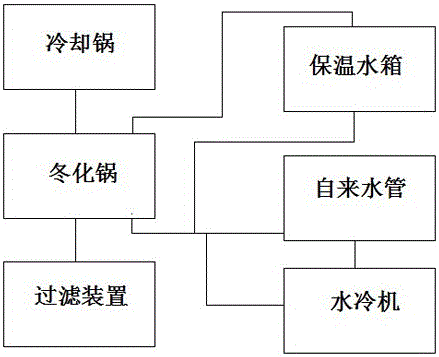

Image

Examples

Embodiment Construction

[0024] The present invention will be described below in combination with specific embodiments.

[0025] Camellia oleifera seed oil winterization method of the present invention comprises the steps:

[0026] Camellia oleifera seed oil winterization method is characterized in that comprising the steps:

[0027] (1) Place the deodorized Camellia oleifera seed oil in a cooling pan and cool it naturally to 40-45°C;

[0028] (2) Put the cooled Camellia oleifera seed oil into the winterization pot and use indoor tap water to cool it for winterization. The winterization temperature is 6-10°C. Stir first and cool down with cold water until the color of the oil in the pot is earthy. Stop stirring and cooling, and grow crystals for 5-7 days until the flocs in the pot are snowflake-like, and then enter the filtration step.

[0029] Naturally cool in a cooling pot to any temperature between 40-45°C, such as 40°C, 41°C, 42°C, 43°C, 44°C, 45°C.

[0030] The winterization temperature can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com