Patents

Literature

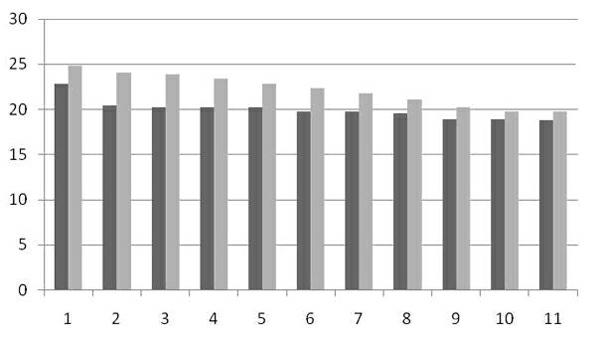

31results about How to "Avoid Yield Impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

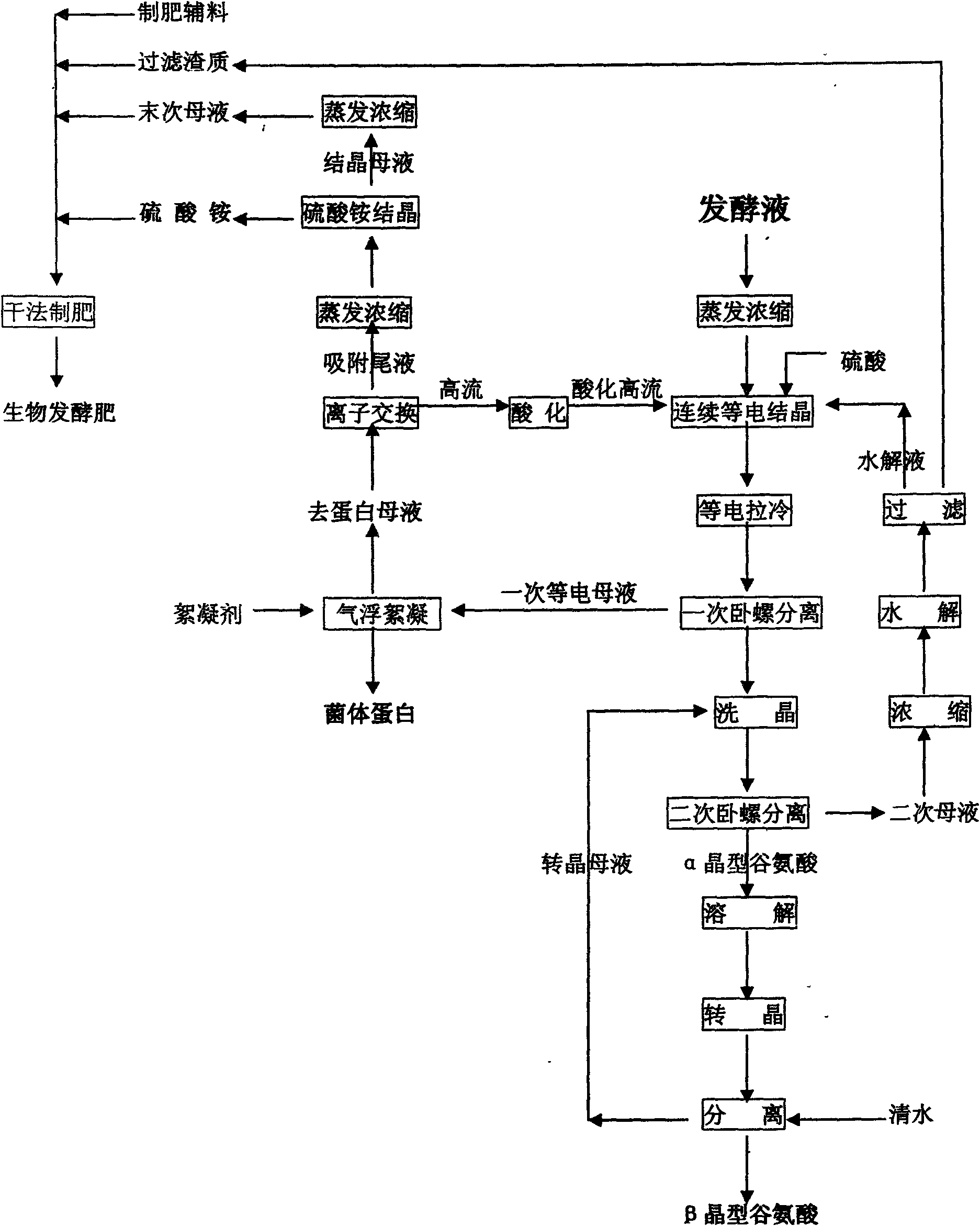

Extraction technology of glutamic acid recovered by combining crystal transformation and ion exchange

InactiveCN101671705AAvoid Yield ImpactHigh crystal purityOrganic compound preparationClimate change adaptationHigh concentrationMycoprotein

The invention relates to an extraction technology of a glutamic acid recovered by combining crystal transformation and ion exchange, belonging to the technical field of food industry. The extraction technology comprises the following technical steps: using the fermentation liquor of the glutamic acid, and heating, evaporating and concentrating the fermentation liquor; cooling the fermentation liquor to 25-50 DEG C after the fermentation liquor is evaporated and concentrated so that the glutamic acid is crystallized and separated out in an alpha form; obtaining an alpha form glutamic acid crystal, a first isoelectric separation mother liquor and a secondary separation mother liquor; enabling the glutamic acid to be crystallized and separated out in a beta crystal form, calling crystal transformation; separating feed liquor to obtain a beta crystal form glutamic acid crystal after the crystal transformation; after the secondary separation mother liquor is concentrated, adding a sulphuricacid to hydrolyze the concentrated secondary separation mother liquor, separating to obtain hydrolysis liquid and solid filter residues, i.e. humus; returning the first isoelectric separation motherliquor to a continuous crystallizing tank, and then using the first isoelectric separation mother liquor as an acid for isoelectric crystallization. The invention achieves the total extraction yield of 97-98 percent, greatly enhances the crystallization purity, greatly reduces the consumption of the sulphuric acid and liquid ammonia, recovers the mycoprotein and thoroughly eliminates the pollutionof high-concentration waste water.

Owner:FUXIN HAOSEN BIOSCI

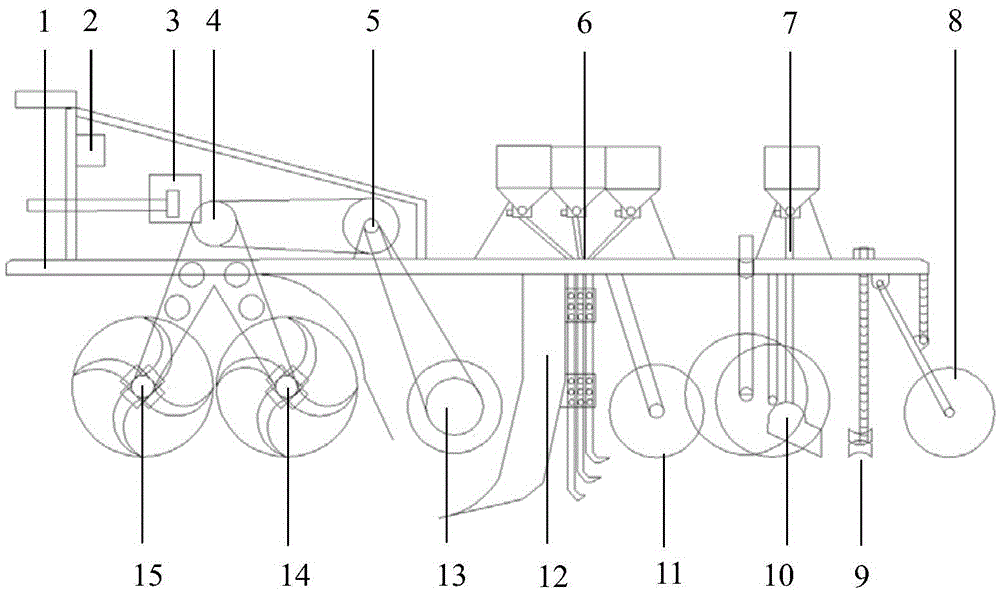

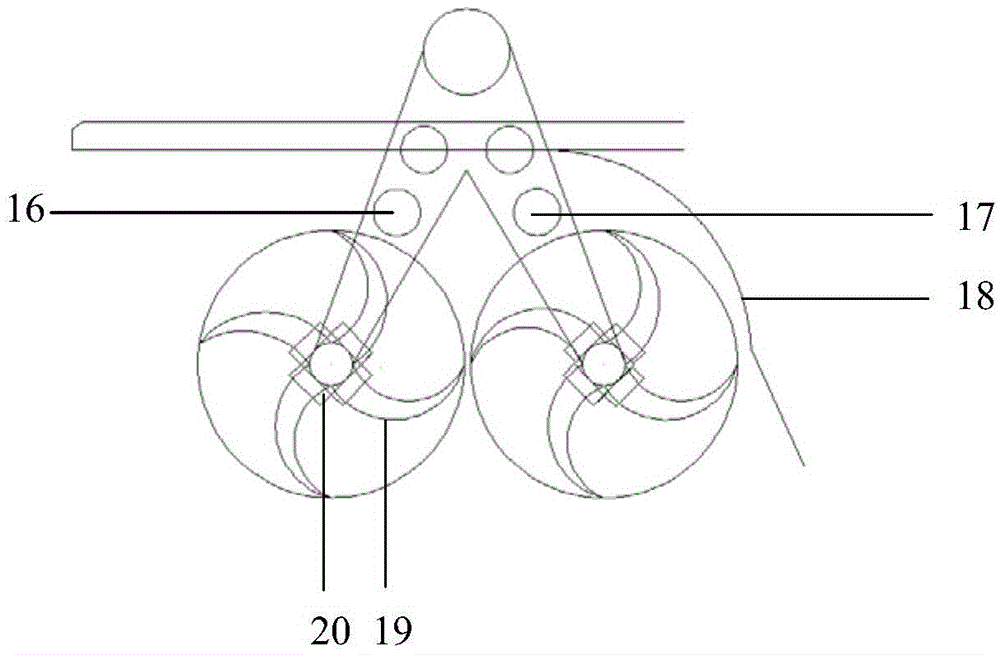

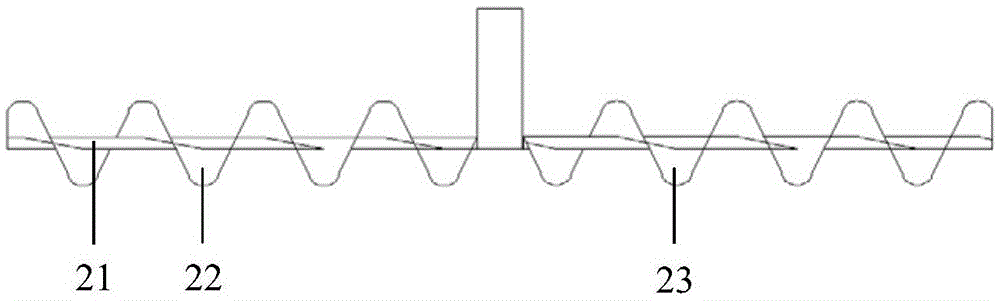

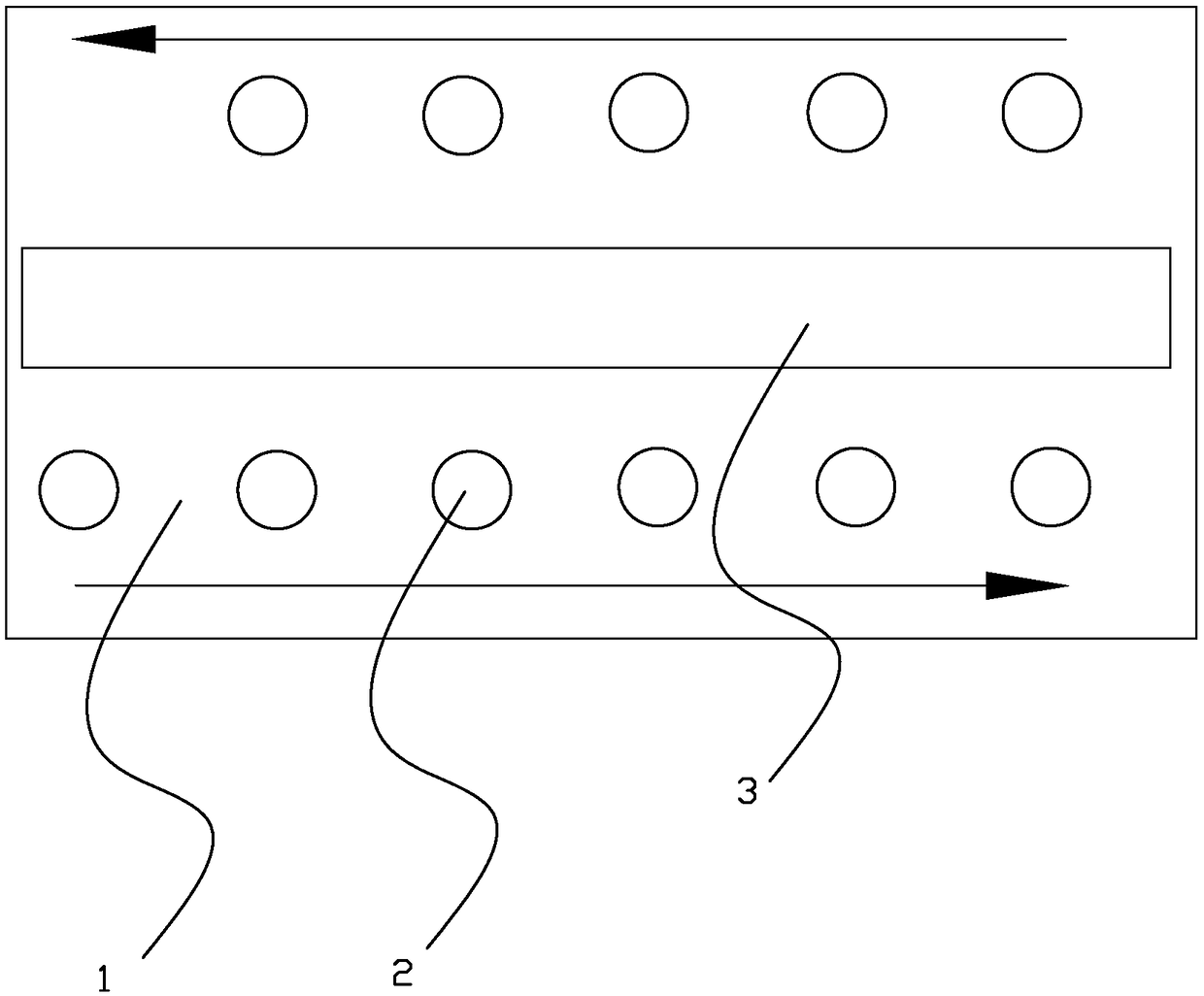

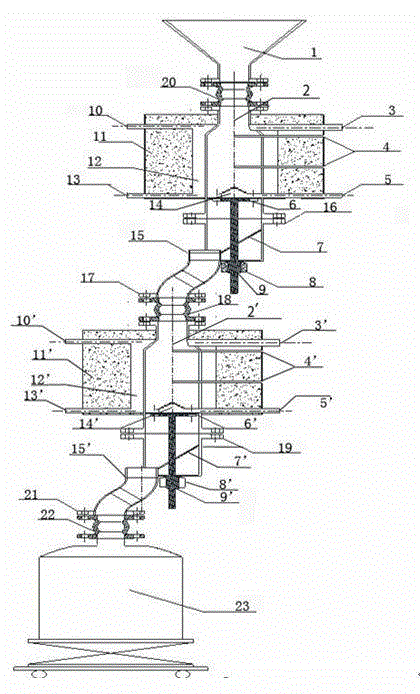

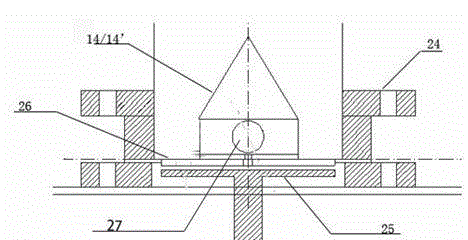

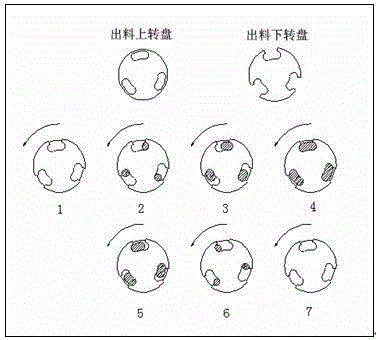

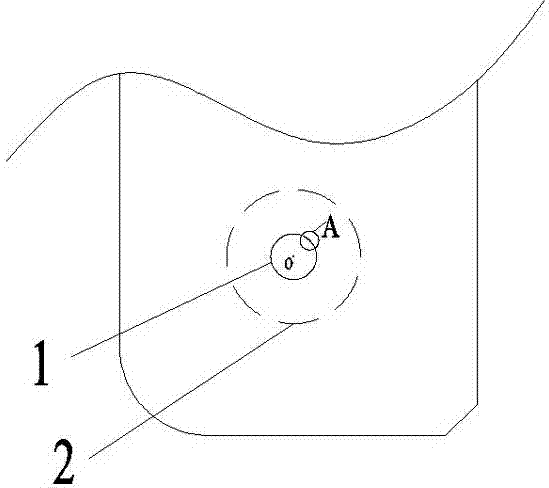

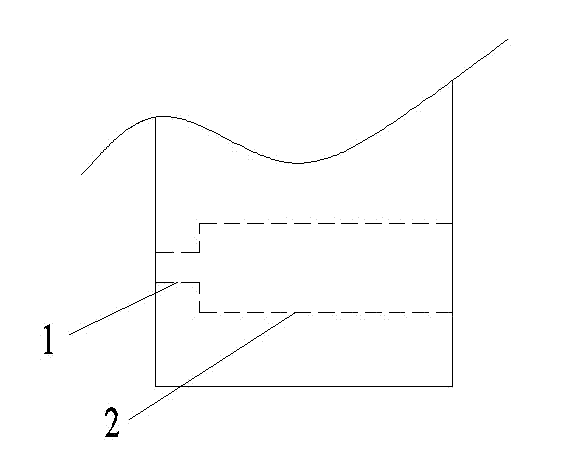

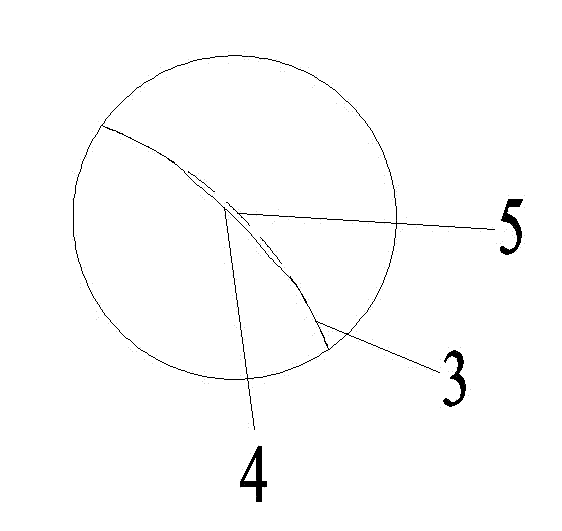

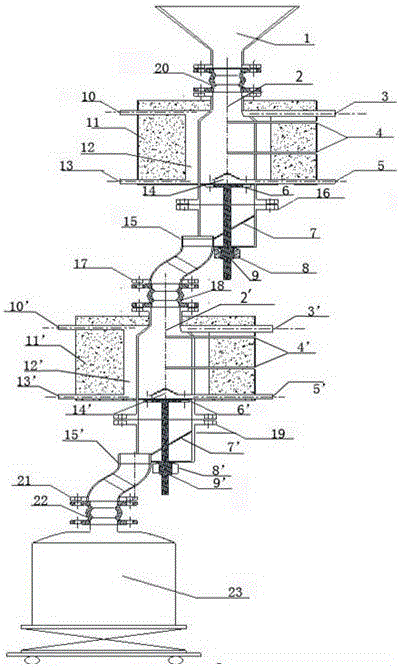

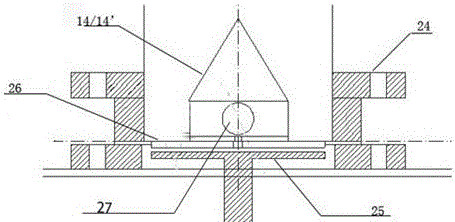

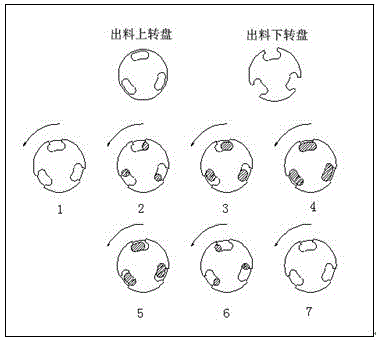

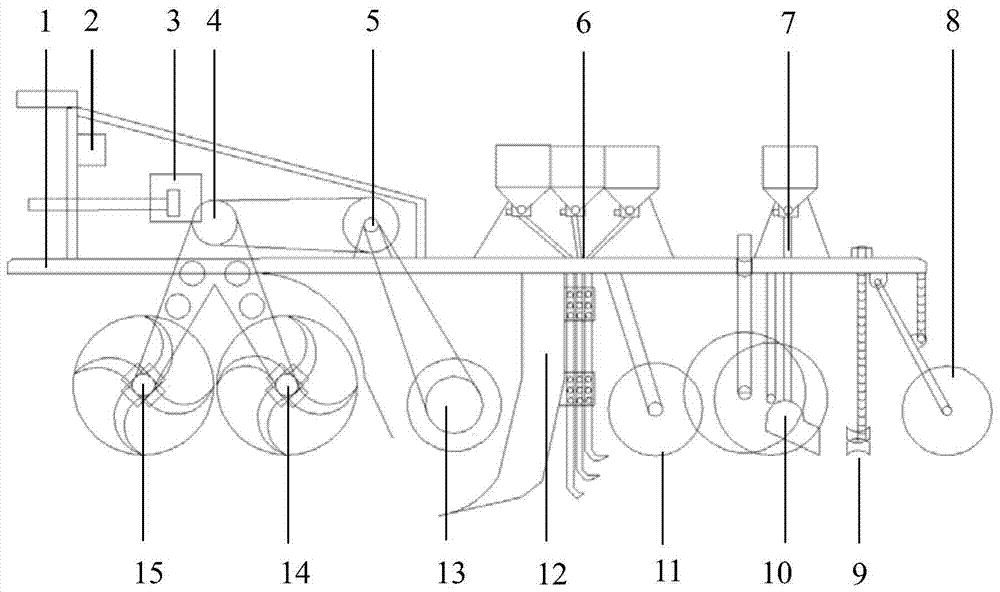

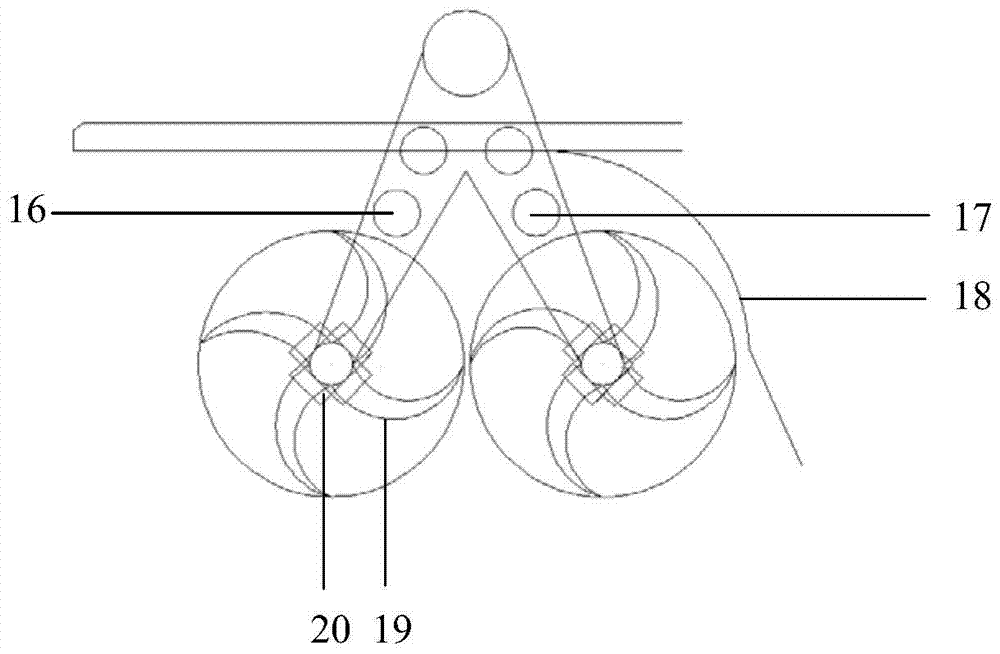

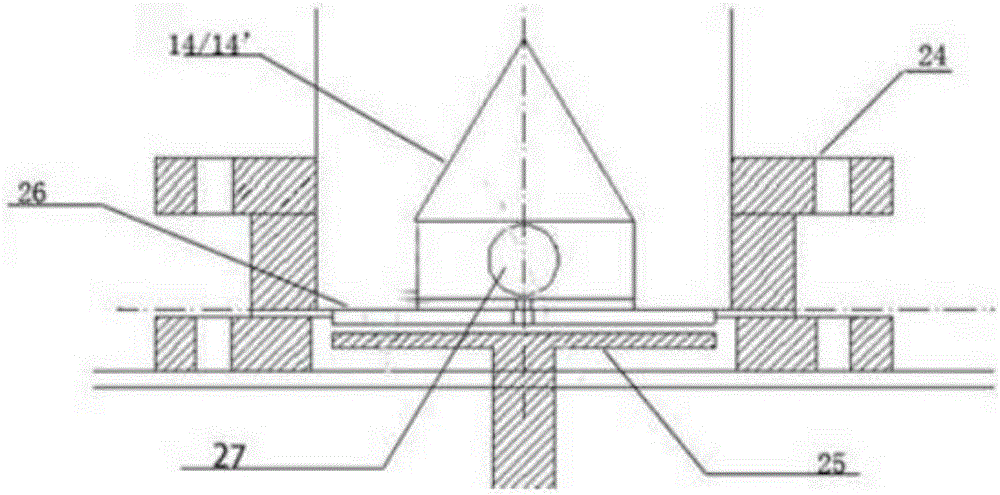

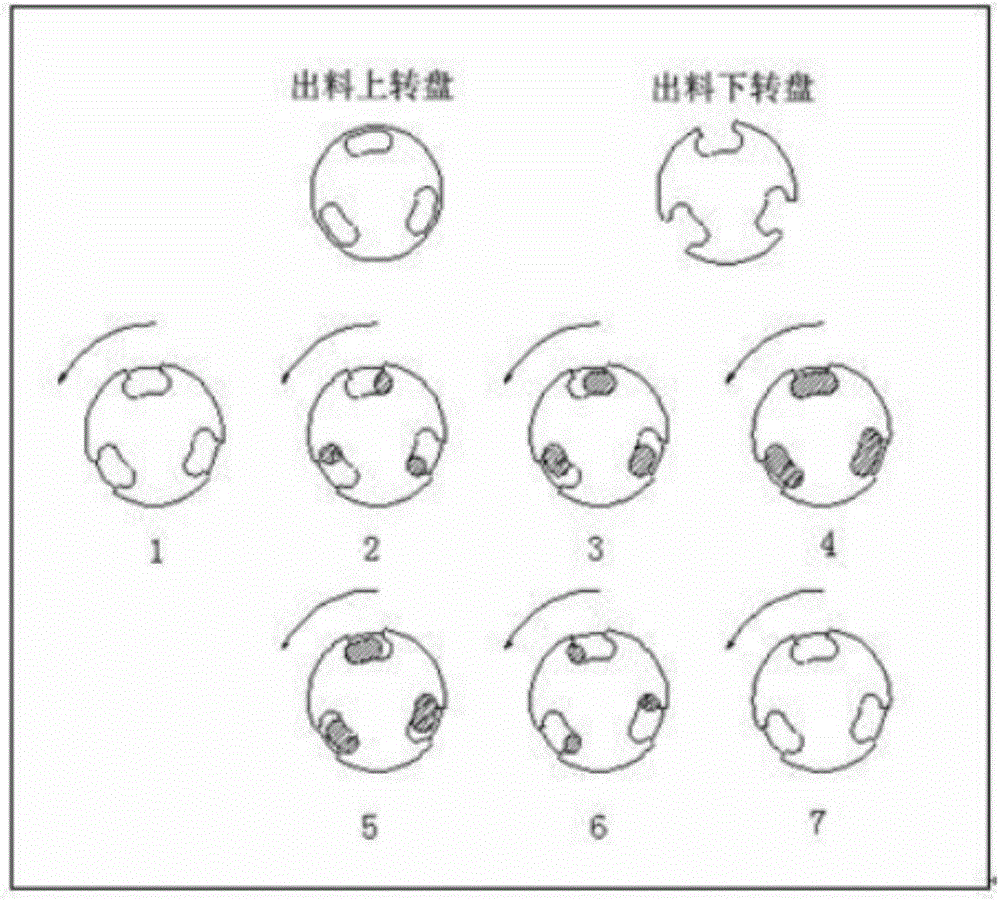

Broad-seedling-width precision sowing machine with functions of double rotary tillage and proportional layering fertilization

ActiveCN105557102AImprove blending uniformityImprove the quality of field returnSpadesSaving energy measuresAnti jammingTerra firma

The invention relates to a broad-seedling-width precision sowing machine with functions of double rotary tillage and proportional layering fertilization. The precision sowing machine comprises a suspended rack, a gearbox, a double-shaft rotary tillage device assembly, an anti-jamming spiral land leveler, a proportional layering fertilization device assembly, a rolling cage harrow, a broad-seedling-width strip sowing device assembly, a cylindrical heavy roller, and a proportional layering fertilization and precision sowing intelligent control system; and the precision sowing machine can sequentially finish operations in links of double rotary tillage for land preparation, spiral blade land leveling for jamming prevention, proportional layering fertilization, land leveling and rolling before sowing, broad-seedling-width precision sowing, rolling after sowing and the like in one time. According to the precision sowing machine, the broad-seedling-width sowing can be realized and a twice throwing and unique multilayer comb strip decentralizing and seed uniformizing structure is adopted, so that seeds can be uniformly distributed in a relatively broad seedling width (8-10cm) range and the space layout structure of seedlings is remarkably improved; and the relationship between a group and an individual is coordinated and a reasonable crop group is created, so that a solid foundation is laid for high yield.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

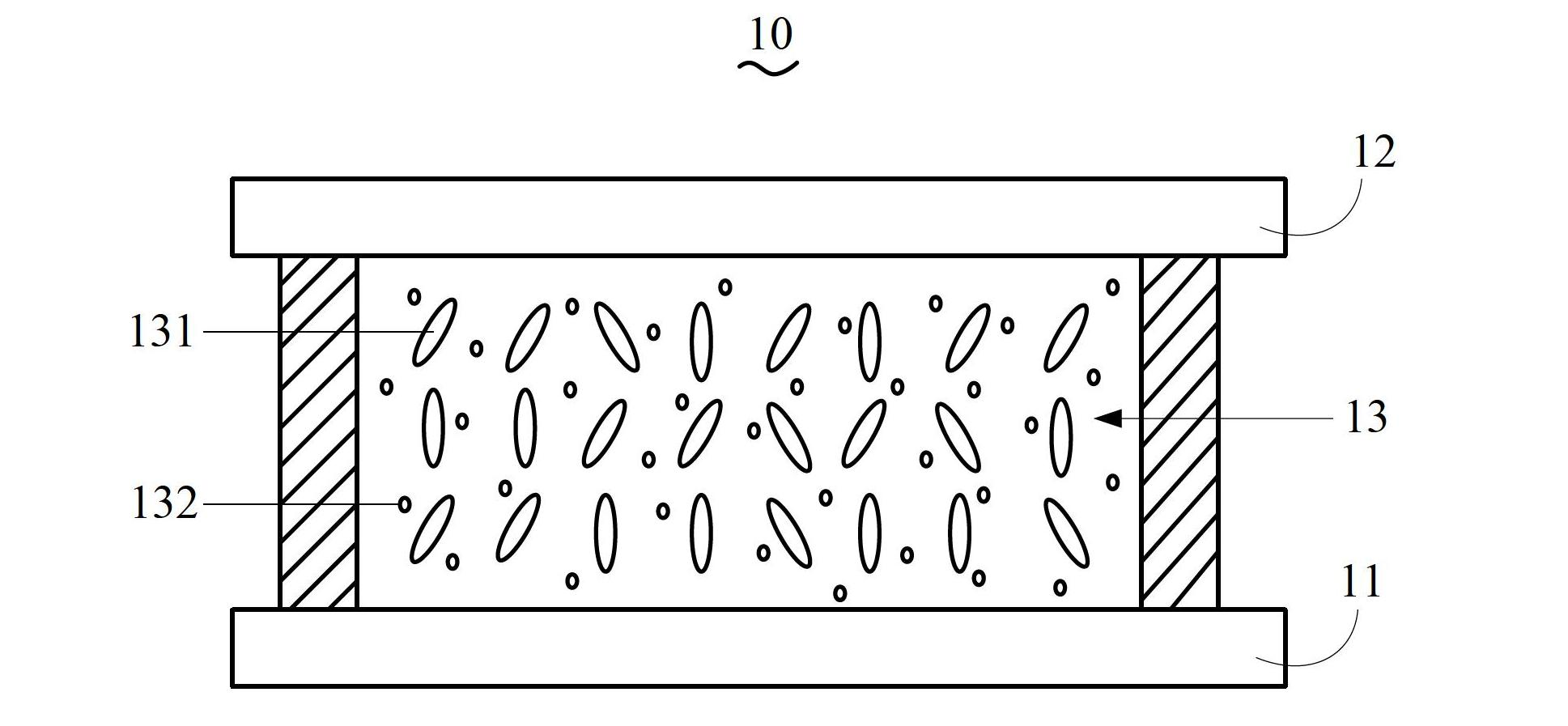

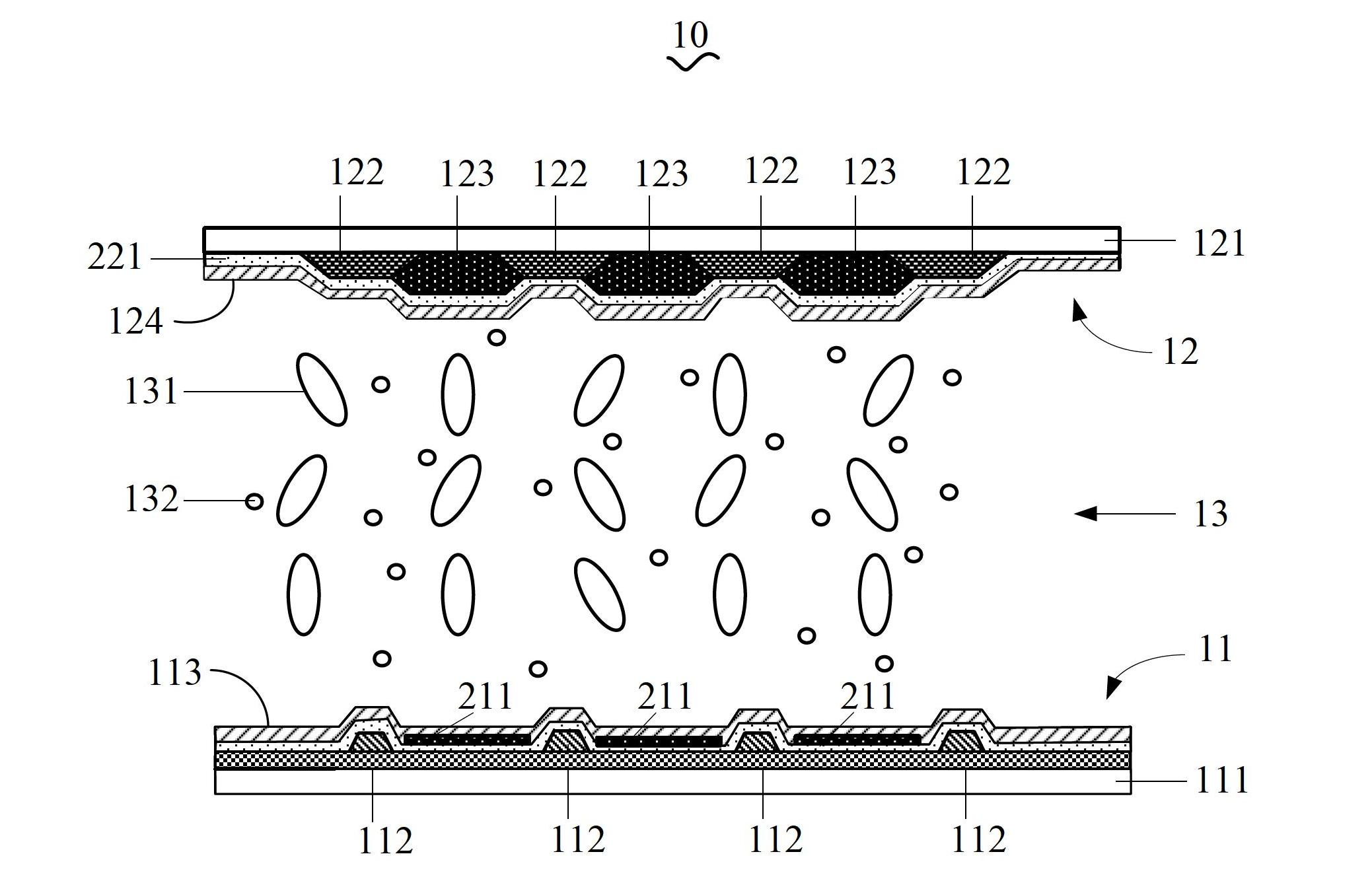

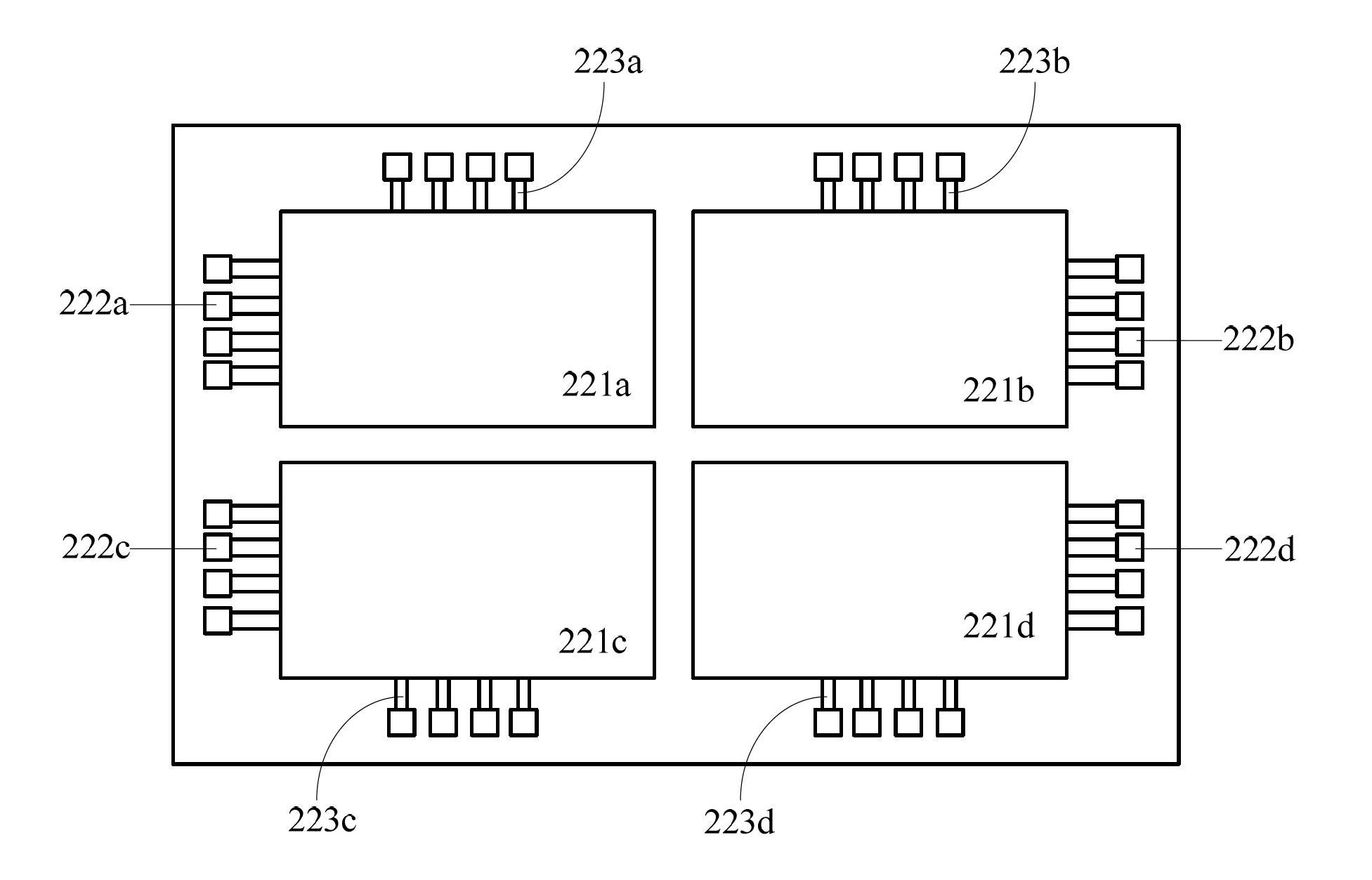

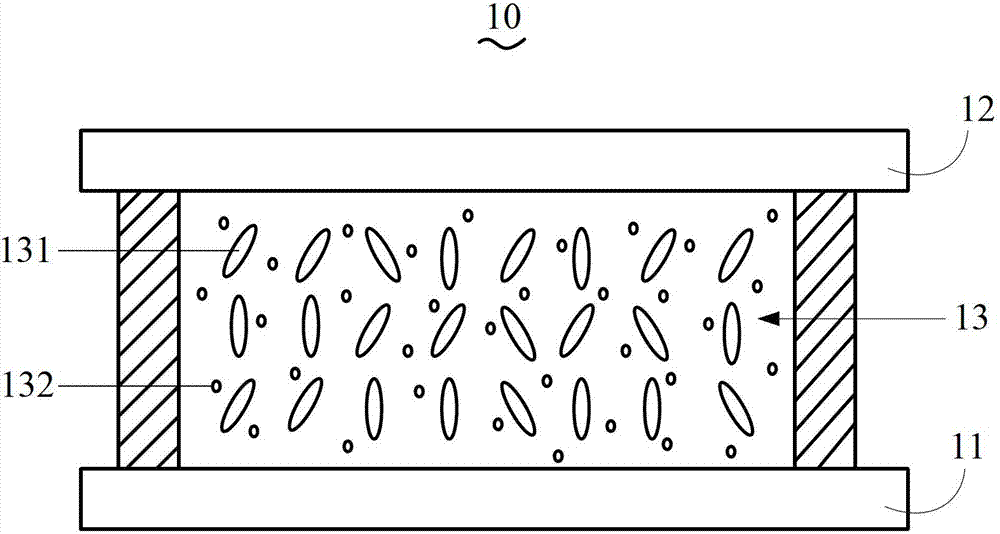

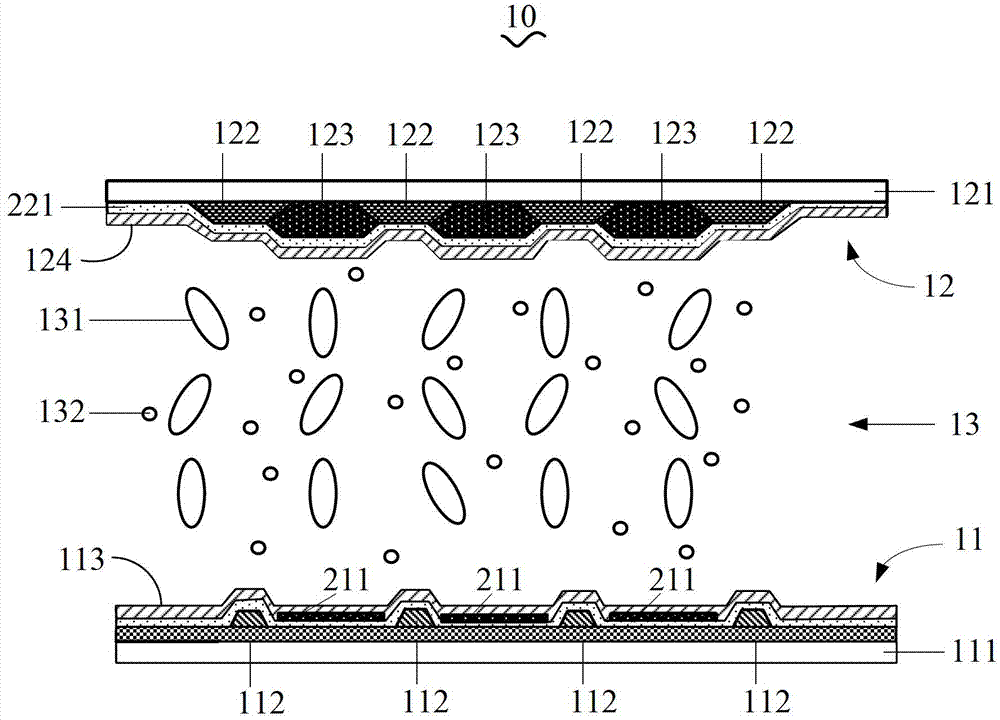

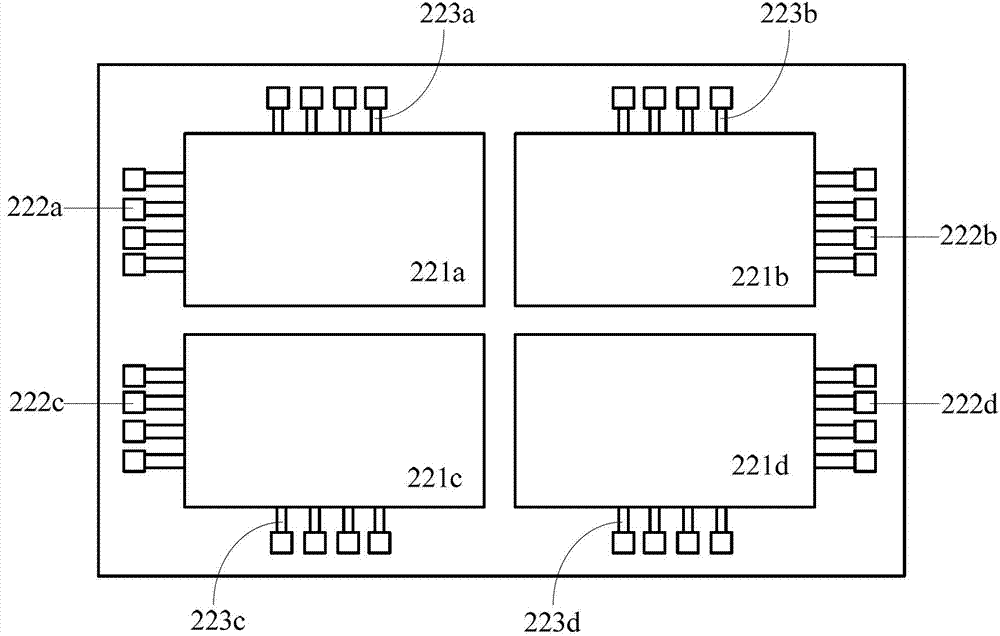

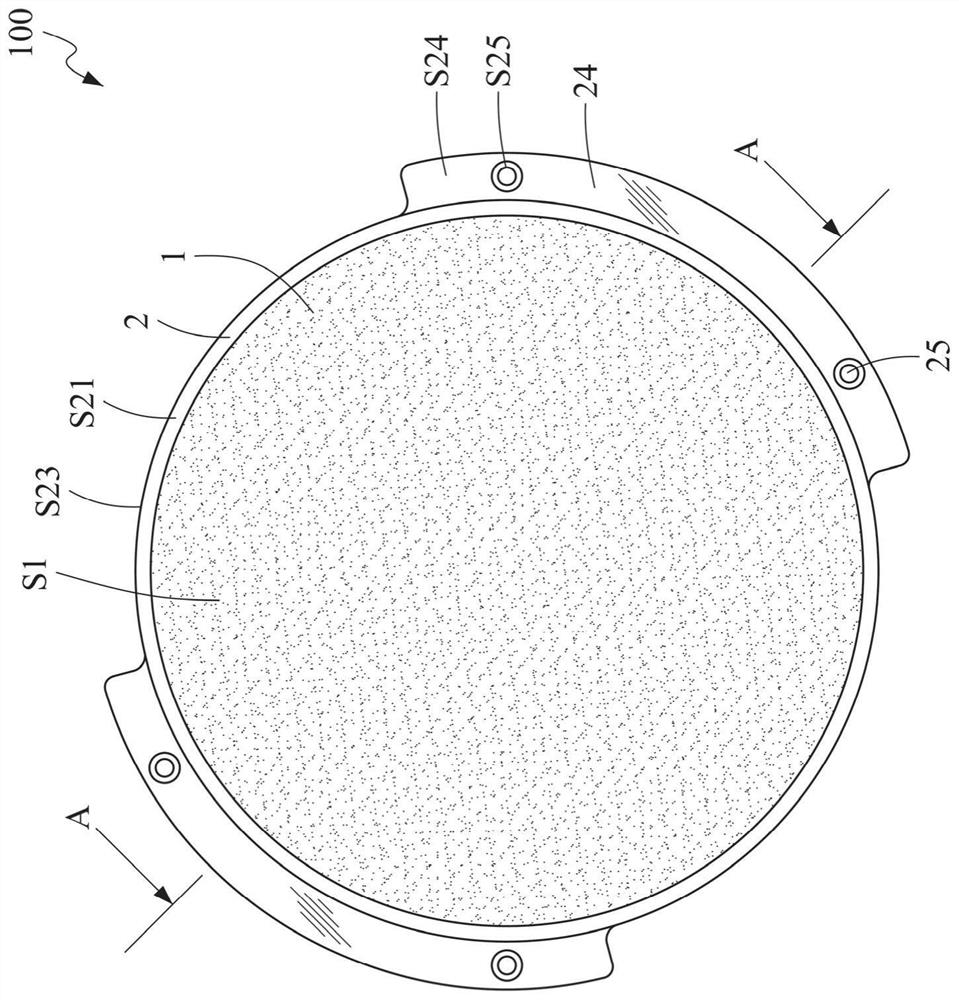

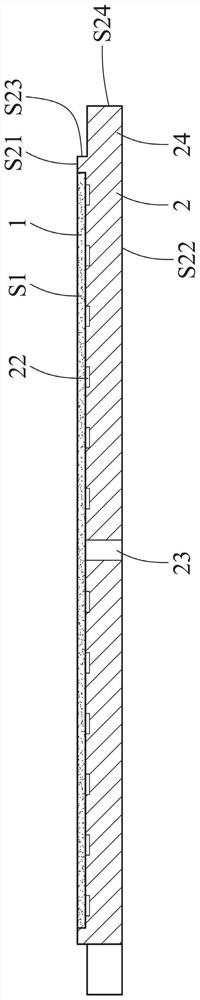

Liquid crystal display device and manufacturing method thereof

The invention provides a liquid crystal display device and a manufacturing method thereof. The liquid crystal display device is provided with a plurality of pixel units. Each pixel unit comprises a liquid crystal layer, a pixel electrode and a counter electrode which are respectively arranged at two opposite sides of the liquid crystal layer, wherein the counter electrode comprises a first electrode pattern and a second electrode pattern, the first electrode pattern is arranged corresponding to the pixel electrode, and the second electrode pattern is connected with the first electrode pattern and used for applying an external voltage to the first electrode pattern, so that an alignment electric field of the liquid crystal layer is formed between the first electrode pattern and the pixel electrode. According to the liquid crystal display device and the manufacturing method thereof, the applying manner of the external voltage is changed, the external voltage is introduced from one side of a color filter substrate, the success ratio of liquid crystal alignment is increased, and thus, the energy consumption is decreased and the waste is reduced.

Owner:CHANGSHA HKC OPTOELECTRONICS CO LTD

Method for constructing cutting orchard for crowned trunk embedding method of cunninghamia lanceolata

InactiveCN108617385AIncrease productionQuality improvementFertilising methodsCultivating equipmentsPlant propagationOrchard

The invention relates to the technical field of plant propagation, and provides a method for constructing a cutting orchard for a crowned trunk embedding method of cunninghamia lanceolata. The methodcomprises the following steps: selecting a nursery ground, carrying out soil preparation and applying a base fertilizer, planting seedlings, shaping the scion cutting mother trees, constructing a scion cutting surface and carrying out hormone treatment, and constructing a photosynthesis surface and carrying out hormone treatment. The method solves the problems that the scion quality is poor, the rejuvenation degree is low, the yield is low, and the service life of the cutting orchard is short in other types of cunninghamia lanceolata cutting orchards.

Owner:福建林业职业技术学院 +3

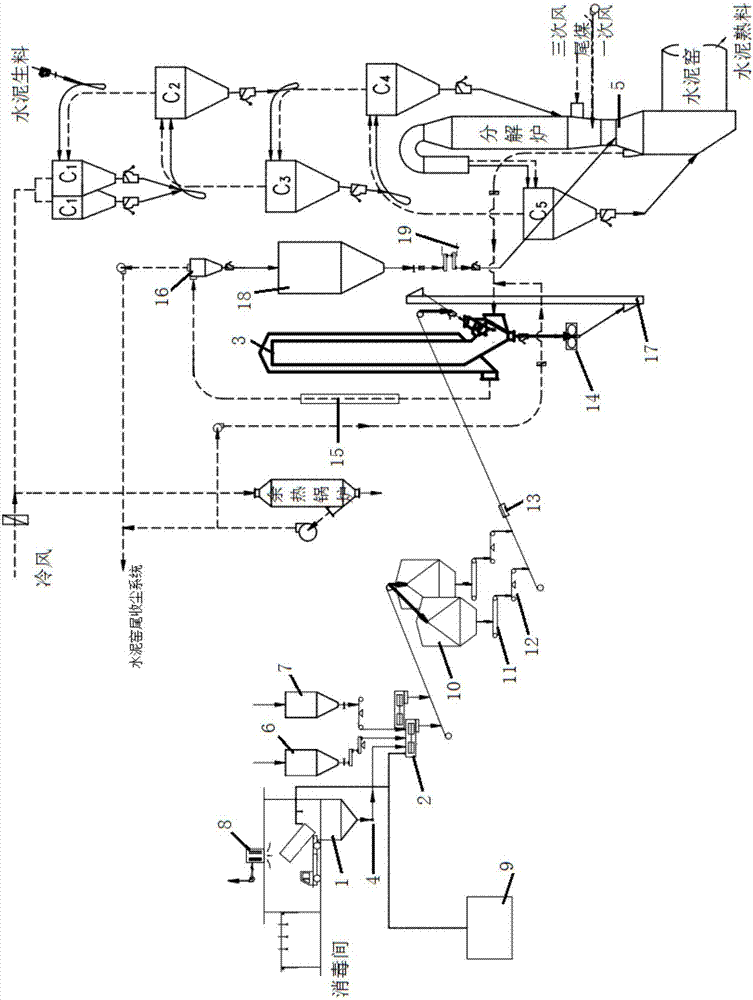

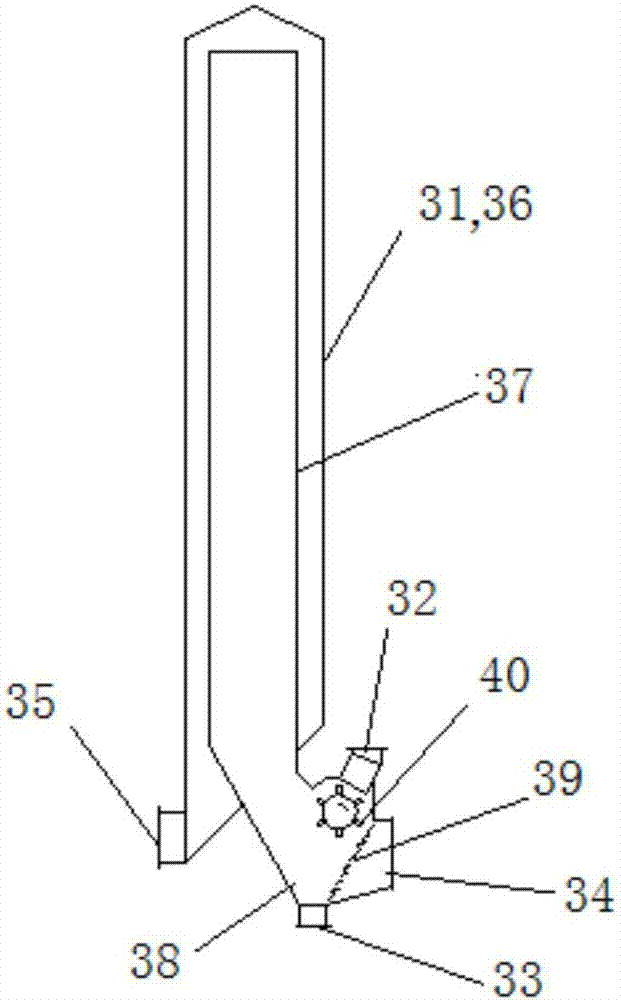

Sludge treatment method and treatment system

PendingCN107417061AEliminate adverse effectsReduce negative impactSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesCo-processingCement kiln

The invention provides a sludge treatment method and treatment system. The treatment method comprises the following steps: discharging sludge into a sludge storage pond, and adding an anti-corrosion modifier and evenly mixing for storage; exporting sludge and delivering sludge into an agitator, and adding an alkaline modifier, evenly mixing and then ageing to obtain a sludge derived cement raw material; entering a vertical bushing dispersing and grading and drying furnace for dispersing, grading and drying, sorting out small-particular materials and large-particular materials, performing further grinding to the large-particular materials, then repeatedly circulating dispersing, grading, drying and grinding processes until all sludge become small--particular materials; and delivering the small-particular materials into a cement kiln tail smoke chamber for incineration. The sludge treatment method and the treatment system effectively overcome the negative influence factor during cooperative treatment of sludge during production in a cement kiln, forcibly conduct anti-corrosion modification to the sludge, reasonably treat waste gas and moisture in sludge, effectively control various effective elements of sludge carried in the cement kiln, avoid the situations influencing the cement kiln, and realizes the harmless treatment of sludge.

Owner:长沙中硅环保科技有限公司

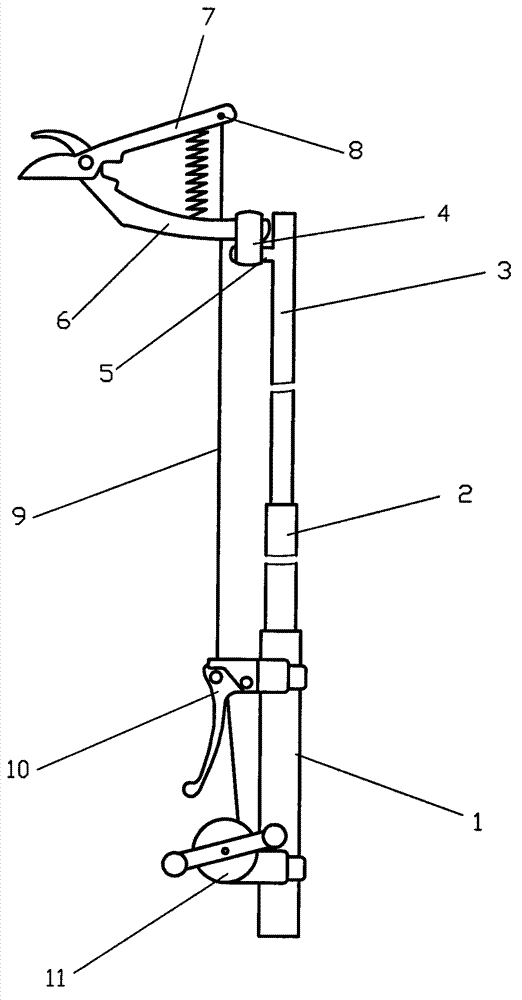

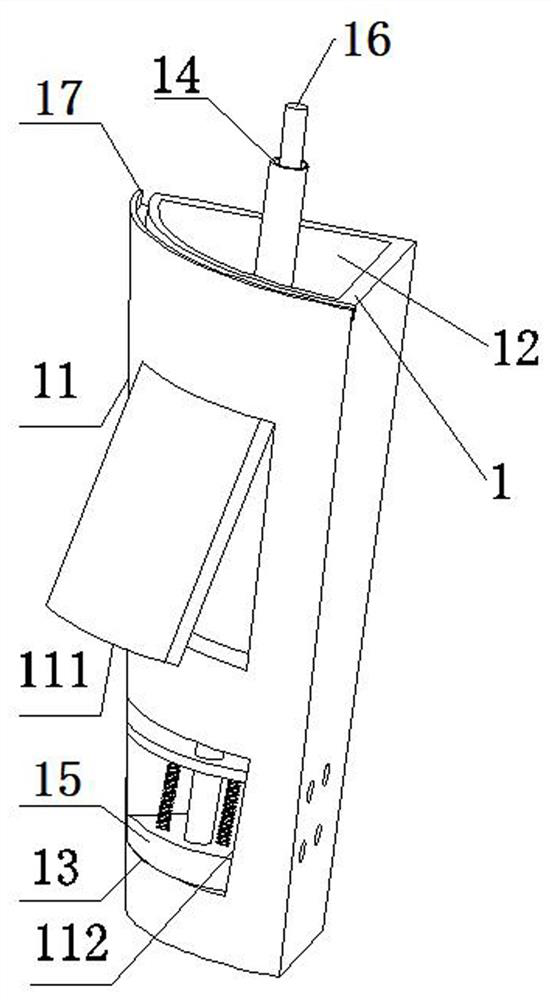

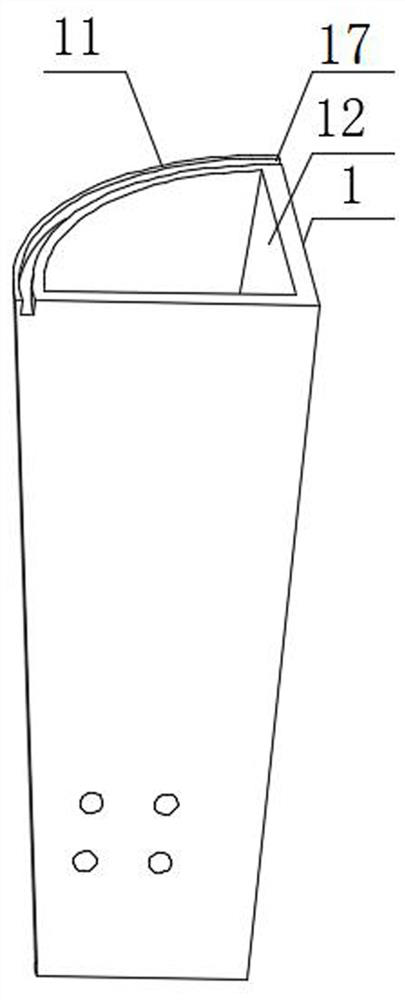

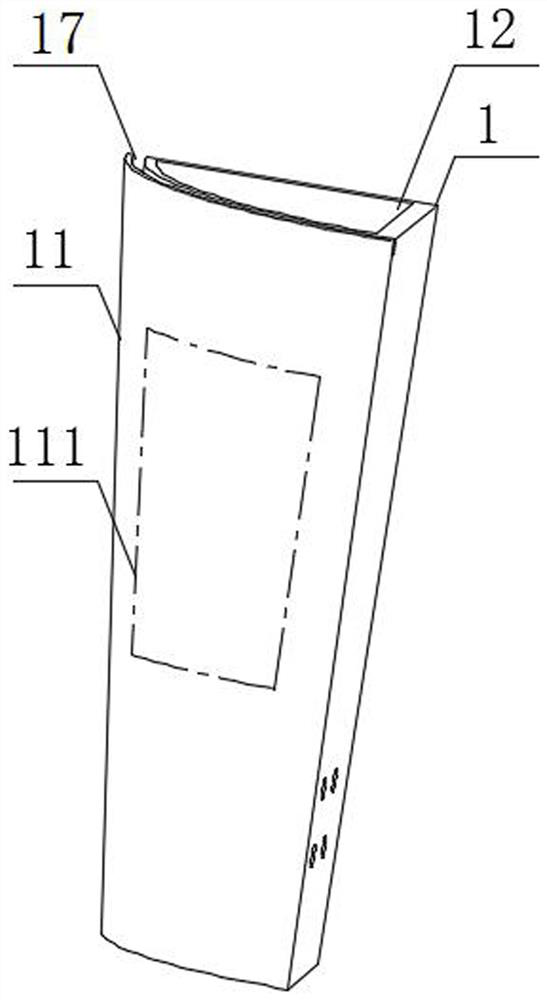

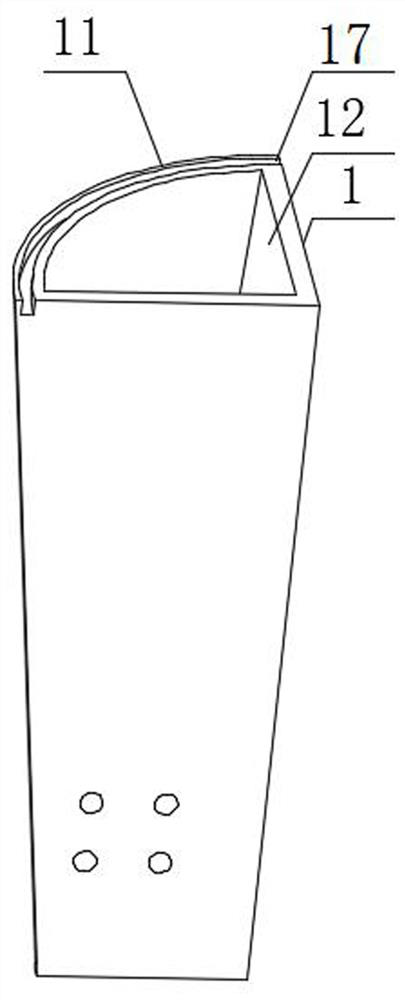

Telescopic high-branch fruit picking device

A telescopic high-branch fruit picking device consists of a tail rod, a middle rod, an end rod, a rubber band, a shear shank frame, a fixed shear shank, a movable shear shank, a line hole, a line, a lever handle and a dropping water wheel. When the telescopic high-branch fruit picking device is used for pruning branches and picking fruits from old trees with high and thin branches which cannot be climbed, the length of a telescopic rod is adjusted according to the height of the branches to be subjected to pruning and fruit picking, the length of the line is controlled through a brake system of the dropping water wheel, and after the line is evenly stressed by using the hand brake type lever handle, a shear controlled by the line and evenly stressed can prune the branches of the fruit trees or pick the fruits of the fruit trees. The purpose of safely picking the fruits can be achieved without climbing and fruit branch destruction.

Owner:康明哲

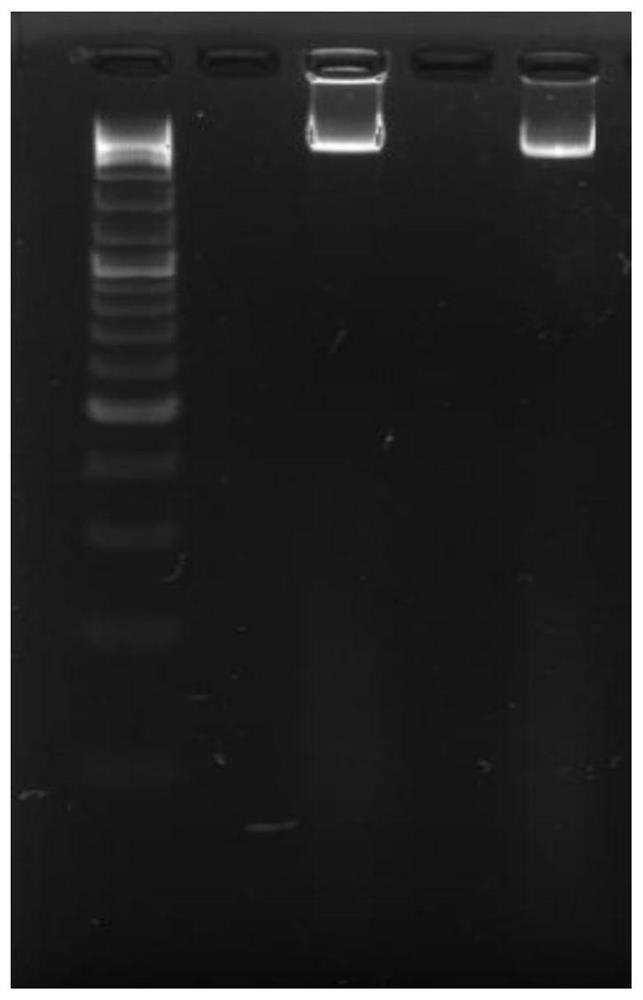

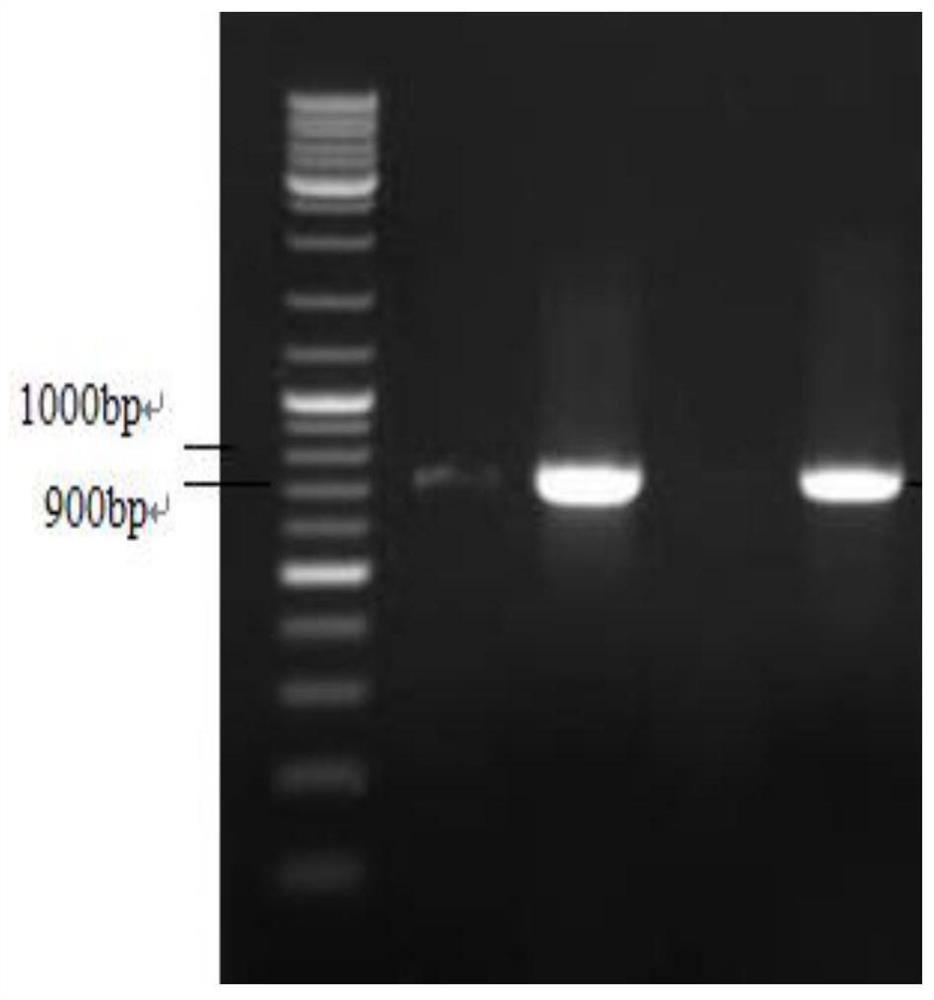

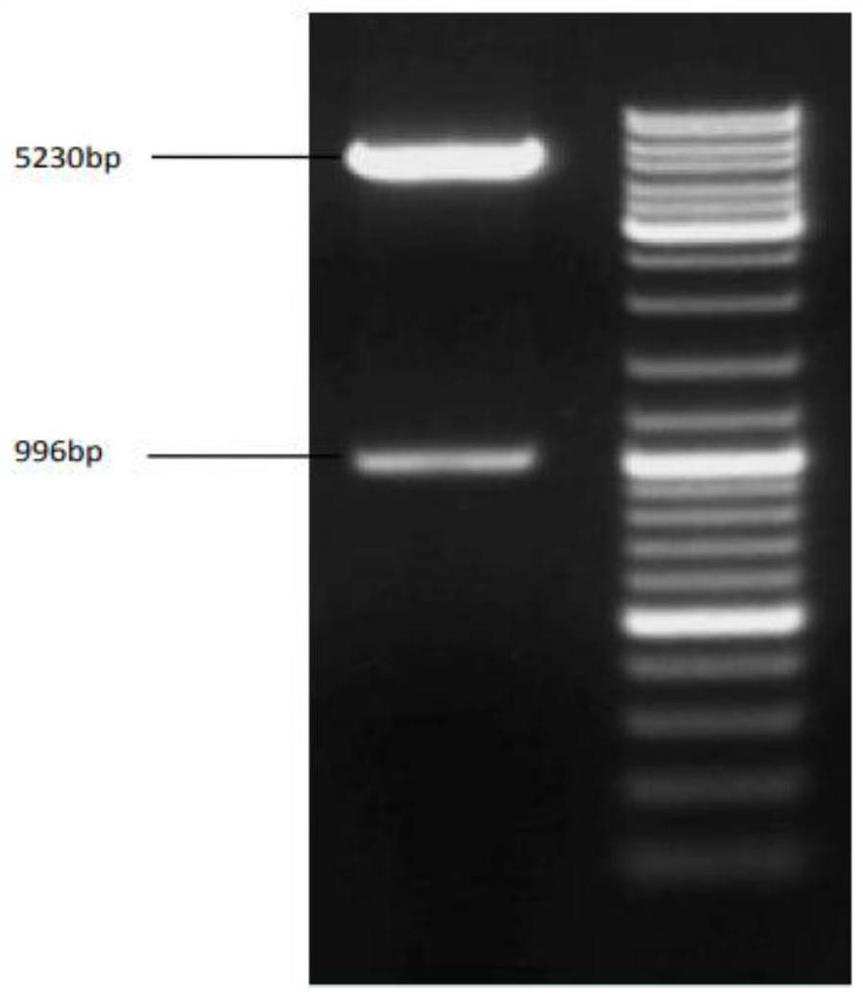

Micro-culture method of pleuromutilin producing bacteria and high-throughput screening method of high-yield bacteria of pleuromutilin

ActiveCN102352317AAdequate nutritional needs for growthThe fermentation process is simpleMicroorganismsHigh-Throughput Screening MethodsScreening method

The invention provides a micro-culture method of pleuromutilin producing bacteria. The method comprises the following steps of: culturing the pleuromutilin producing bacteria and then separating a single bacterial colony; preparing a solid fermentation culture medium and sterilizing at a high pressure, and then adding the sterilized solid fermentation culture medium into each pore of an enzyme label plate; inoculating mycelia of the single bacterial colony generated by the pleuromutilin producing bacteria into the enzyme label plate and culturing for 7-9 days. The invention also provides a high-throughput screening method of high-yield bacteria of the pleuromutilin. The high-throughput screening method comprises the following steps of: adding extraction liquid into the pores of the enzymelabel plate of the micro-cultured pleuromutilin producing bacteria to extract; sucking the extraction liquid for each pore and transferring to another enzyme label plate; adding a color-developing agent to develop; measuring by using an enzyme label meter and analyzing the result to obtain the screened high-yield bacteria of the pleuromutilin. As the solid fermentation is adopted, the step of culturing seeds is simplified and the fermentation time is greatly shortened. Compared with the common screening method, the high-throughput screening method has a good related coefficient, thereby beingapplied to screening of the high-yield bacteria of the pleuromutilin.

Owner:LANZHOU INST OF ANIMAL SCI & VETERINARY PHARMA OF CAAS

Nut and dried fruit bar and production process thereof

The invention provides a nut and dried fruit bar and a production process thereof. Compared with the prior art, the nut and dried fruit bar organically combines smashed biscuits, smashed nuts and dried fruits, and the prepared product is rich in nutrient; meanwhile, in the production process, by means of multiple times of water spraying operation by means of a spraying kettle, material surfaces are wetted, the materials can not be added at a time, and it is avoided that the materials are wetted by water too much and the product taste is affected; meanwhile, the adhesiveness of the raw materials is higher, and it is avoided that crumbs are generated to affect the selling appearance and yield of the product. Due to the baking temperature and the time, the product taste is ensured, and nutrients are not lost; then, fire spraying is conducted through a fire spraying gun, the product is fired for 2-3 seconds, the combination of the materials is closer, crumbs can not be easily produced, obvious sugar particles or powder particles on surfaces can be fired and melted, and the product has a better selling appearance.

Owner:ANHUI THREE SQUIRRELS ELECTRONICS BUSINESS

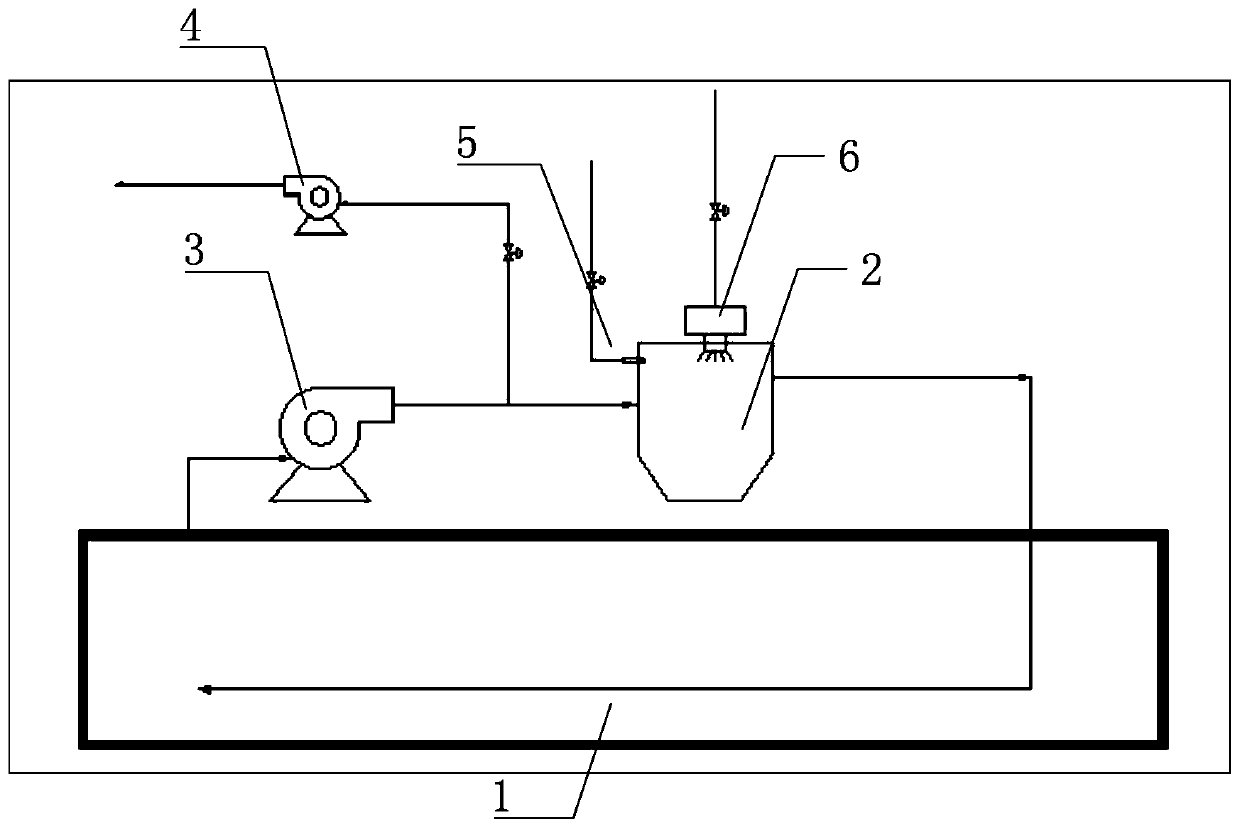

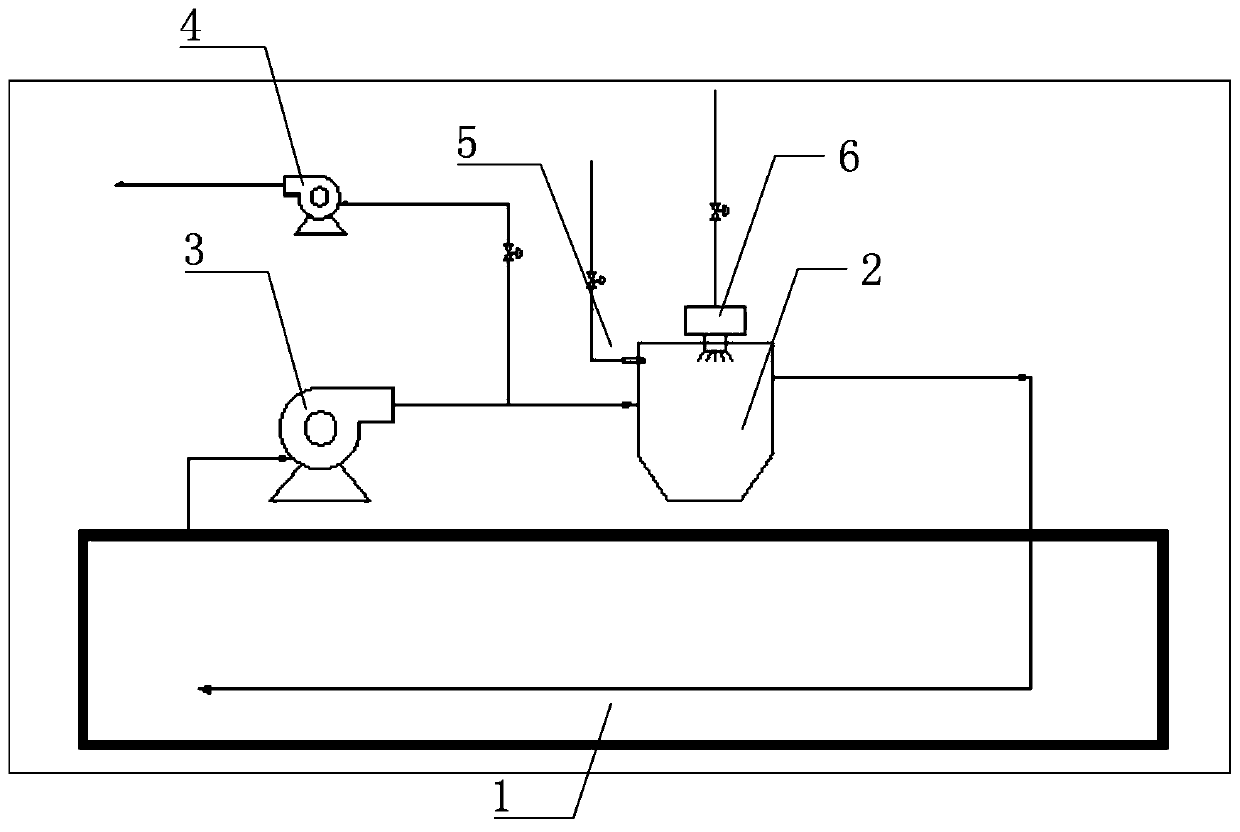

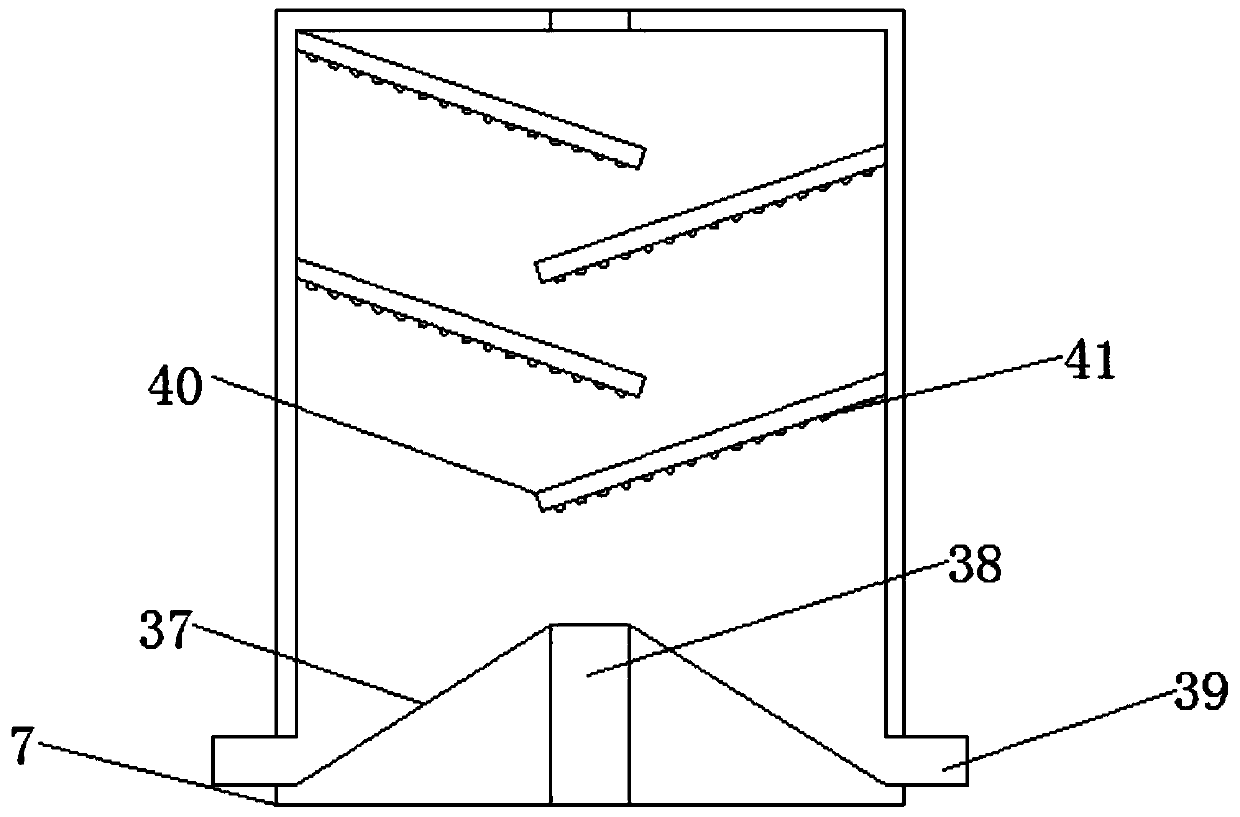

Direct combustion type efficient and energy-saving humidity control denitration catalyst drying system

InactiveCN110006229AImprove heat utilization efficiencyHigh degree of automationDrying gas arrangementsDrying safety systemsWater pipeCombustion chamber

The invention relates to a direct combustion type efficient and energy-saving humidity control denitration catalyst drying system, and belongs to the technical field of denitration catalyst productionequipment. The direct combustion type efficient and energy-saving humidity control denitration catalyst drying system comprises a primary drying chamber, a combustion control system and a humidification control system are connected to an inlet of the primary drying chamber, a circulating fan and a dehumidifying fan are connected to an outlet of the primary drying chamber, the top of a combustor is connected with a natural gas pipeline, and the bottom of the combustor is connected with a combustion chamber; the top of a humidifying atomization device is connected with a water supplying water pipe, and the bottom of the humidifying atomization device is connected with the combustion chamber; an outlet of the circulating fan is connected with the combustion chamber and the dehumidifying fan,and the dehumidifying fan is directly evacuated; and the primary drying chamber is provided with a humidity detector and a temperature detector. According to the technical scheme, the direct combustion type efficient and energy-saving humidity control denitration catalyst drying system has the beneficial effects that no heat loss of a steam pipeline is generated, and the heat utilization efficiency is nearly 100%; heat generated through combustion of the combustor and jetted water form flue gas containing specific humid and heat and enter the primary drying chamber together, safety and reliability are achieved, the problem that the temperature and the humidity are difficult to control is solved, and the catalyst finished product rate is guaranteed; and the automation degree is high, and operation is easy.

Owner:荣卫龙

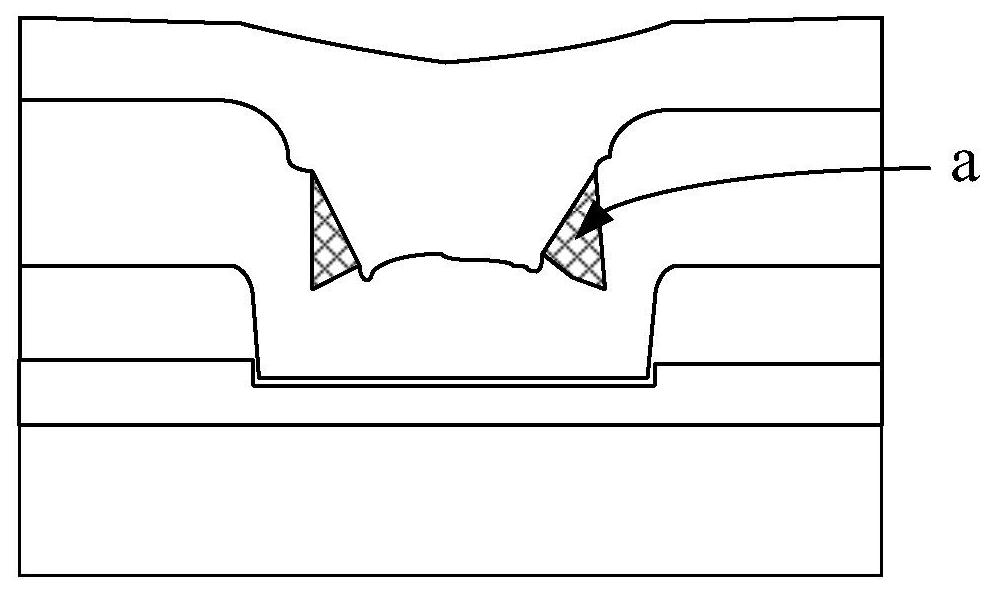

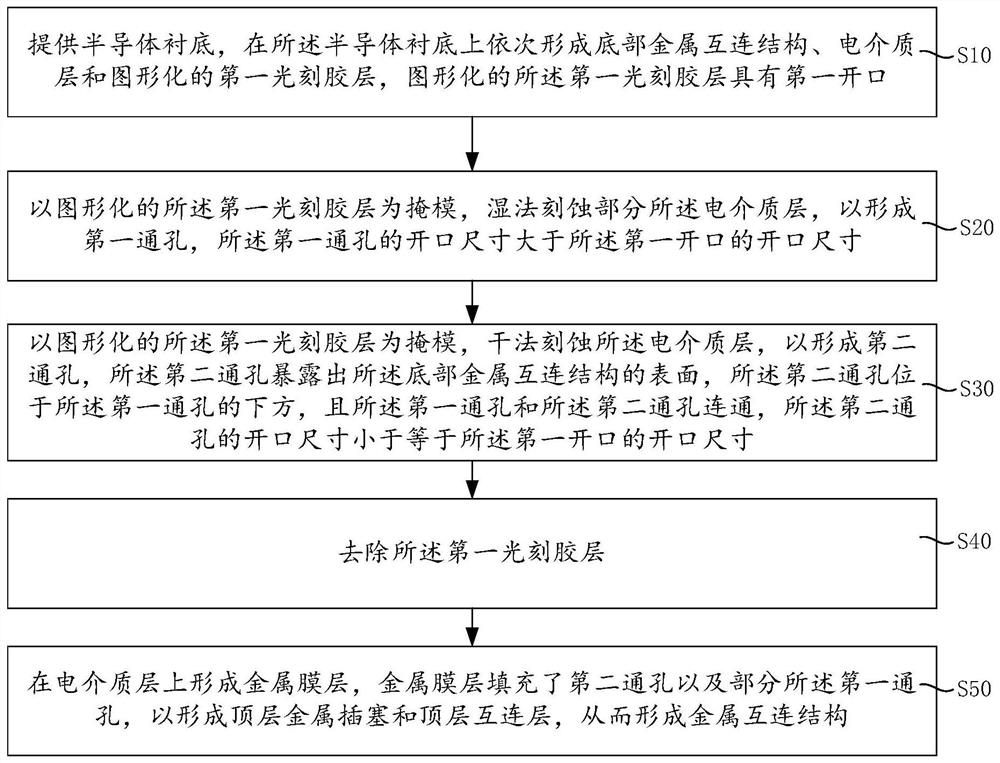

Forming method of metal interconnection structure

PendingCN112201620ADepth width reductionAvoid the impact of service lifeSemiconductor/solid-state device manufacturingMetal membraneProtection layer

The invention provides a forming method of a metal interconnection structure. A first through hole is formed through wet etching firstly, then a second through hole is formed through dry etching, thefirst through hole is communicated with the second through hole, the first through hole is located above the second through hole, and due to the fact that the opening size of the first through hole islarger than that of the second through hole, The overall depth and width of the first through hole and the second through hole after communication are reduced, and when a metal film layer and a protective layer are formed subsequently, protective layer residues do not appear on the surface of a top metal plug, so that influence of the protective layer residues on the product yield during subsequent packaging is avoided, and influence of the service life of the electrical test equipment (probe) during the WAT test is also avoided.

Owner:NEXCHIP SEMICON CO LTD

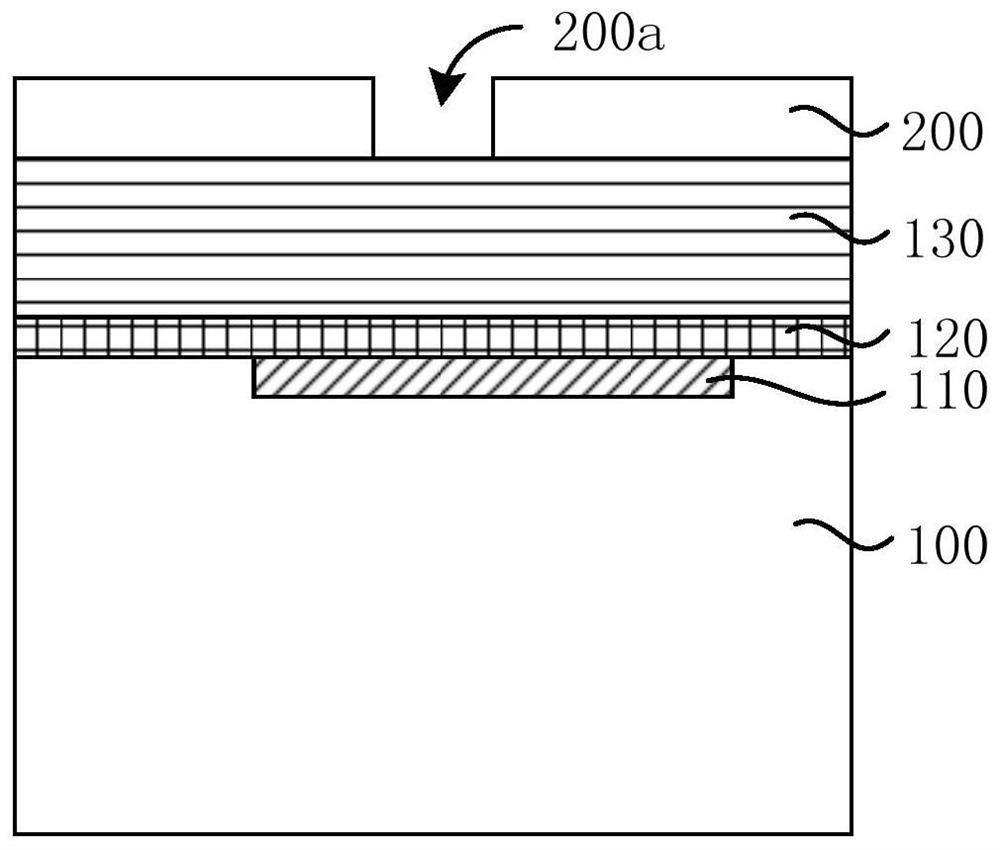

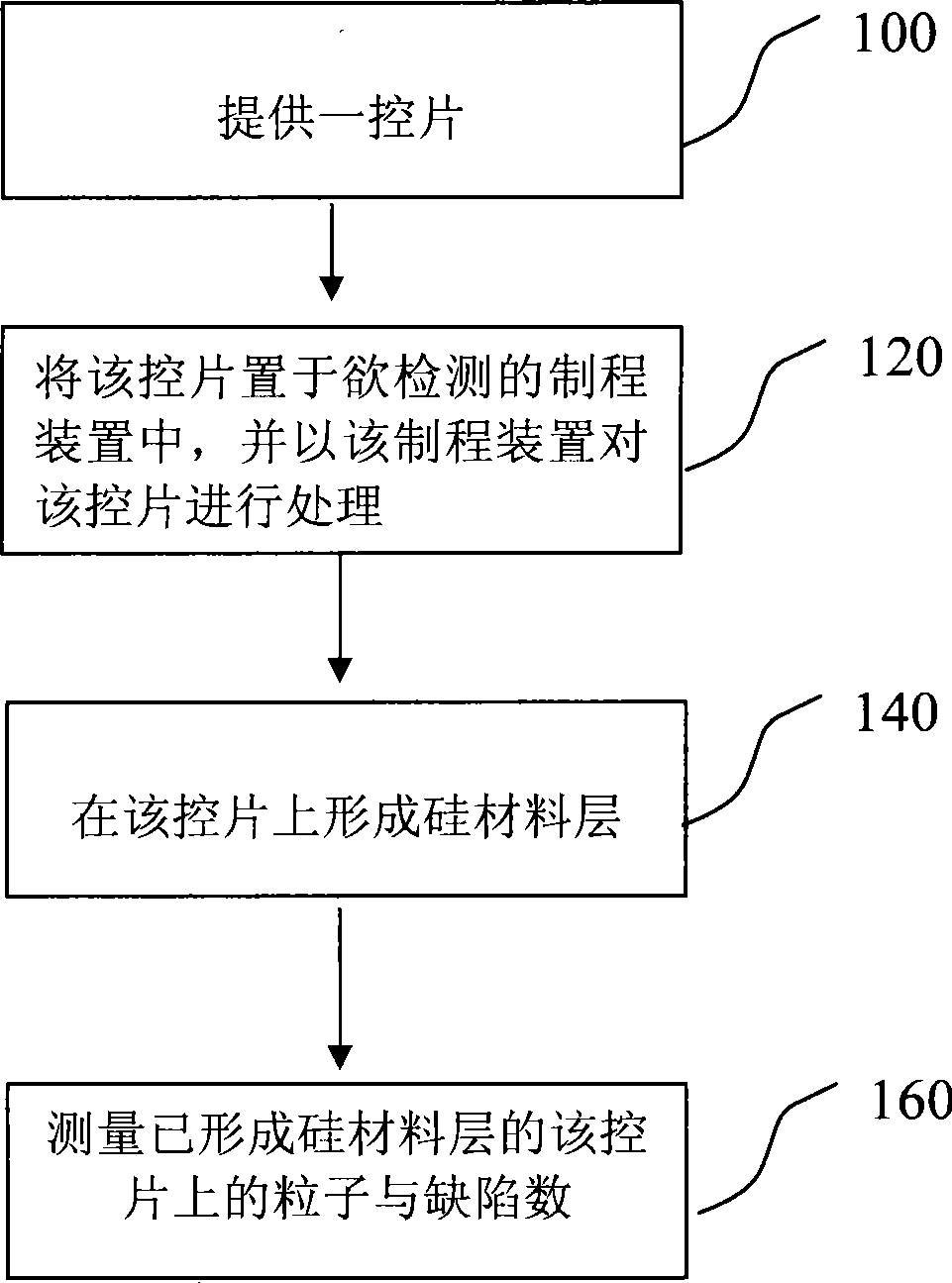

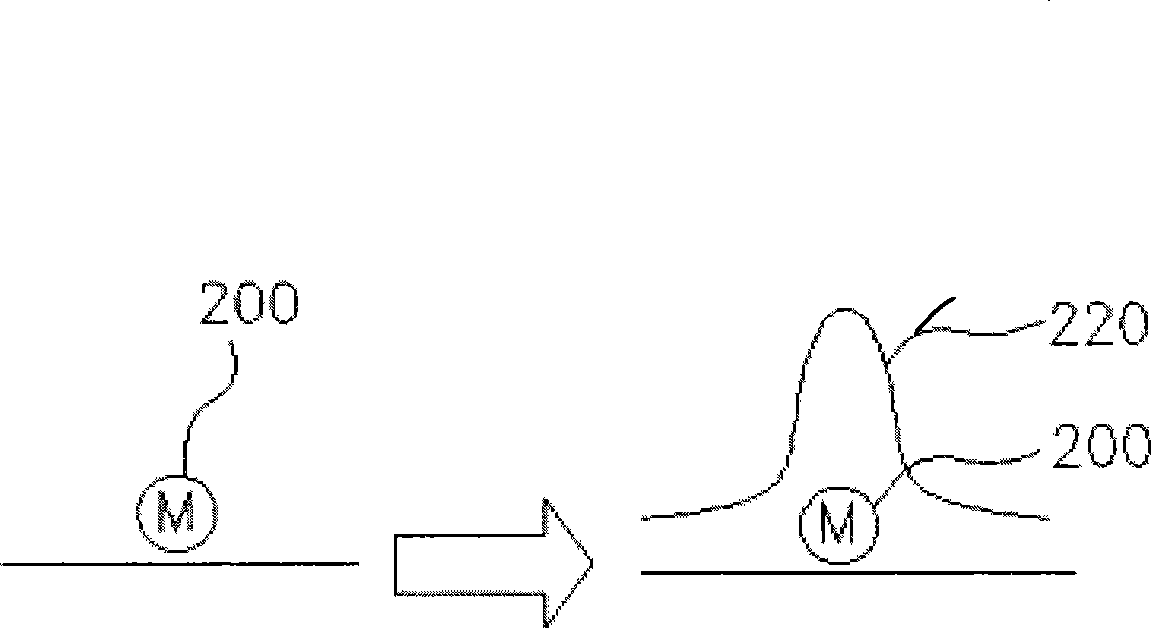

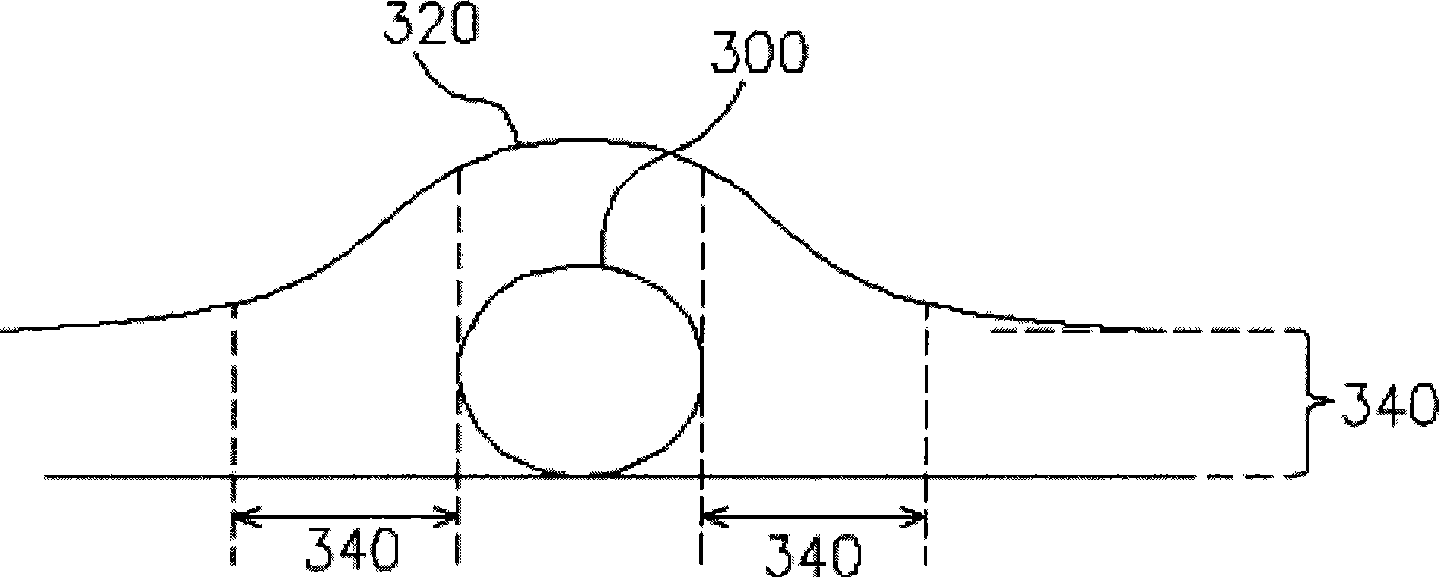

Method for manufacturing detection chip for measuring and checking numbers of particles and defects on chip

InactiveCN101363780AGood effectAvoid Yield ImpactMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementSiliconMaterials science

The invention relates to method for manufacturing a detection chip for measuring and inspecting the particles and the number of defects on a chip. The method comprises the steps of providing a blank chip; placing the blank chip in a manufacture procedure device to be detected; using the manufacture procedure device to process the blank chip; and forming a silicon material layer on the blank chip. The blank chip with silicon material layer can directly measure the particles and the number of defects, that is, the metal pollution and the micro-particle pollution degree in the manufacture procedure device can be obtained.

Owner:MACRONIX INT CO LTD

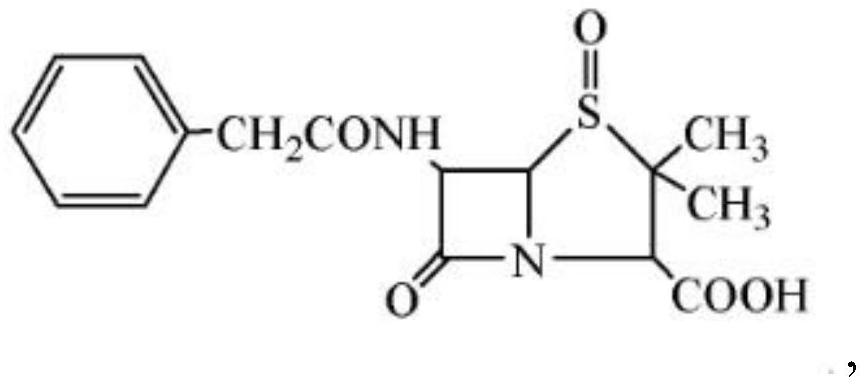

Low-rank coal adiabatic pyrolysis device

InactiveCN104610990ASimple structureGood insulation effectDirect heating destructive distillationSpecial form destructive distillationExhaust gasQuenching

The invention relates to a low-rank coal adiabatic pyrolysis device which is composed of a charging hopper, an adiabatic drying chamber, an adiabatic dry distillation chamber and a coke quenching tank which are communicated in sequence, wherein the adiabatic drying chamber is the same as the adiabatic dry distillation chamber in diameter and size; gas insulation layers which have the same temperature as the adiabatic drying chamber and the adiabatic dry distillation chamber are respectively arranged on the peripheries; outer insulation layers are respectively arranged on the peripheries of the adiabatic drying chamber and the adiabatic dry distillation chamber. The low-rank coal adiabatic pyrolysis device is simple in structure and good in adiabatic effect, coal materials move downwards by means of gravity, tail gas generated in the drying process and tail gas generated in the pyrolysis process are separately processed, the retention time of discharge quantity is easy to control, and the air inlet temperature is basically consistent with the center temperature of a reactor, so that the pyrolysis efficiency of a coal pyrolysis reactor is greatly improved.

Owner:TAIYUAN UNIV OF TECH

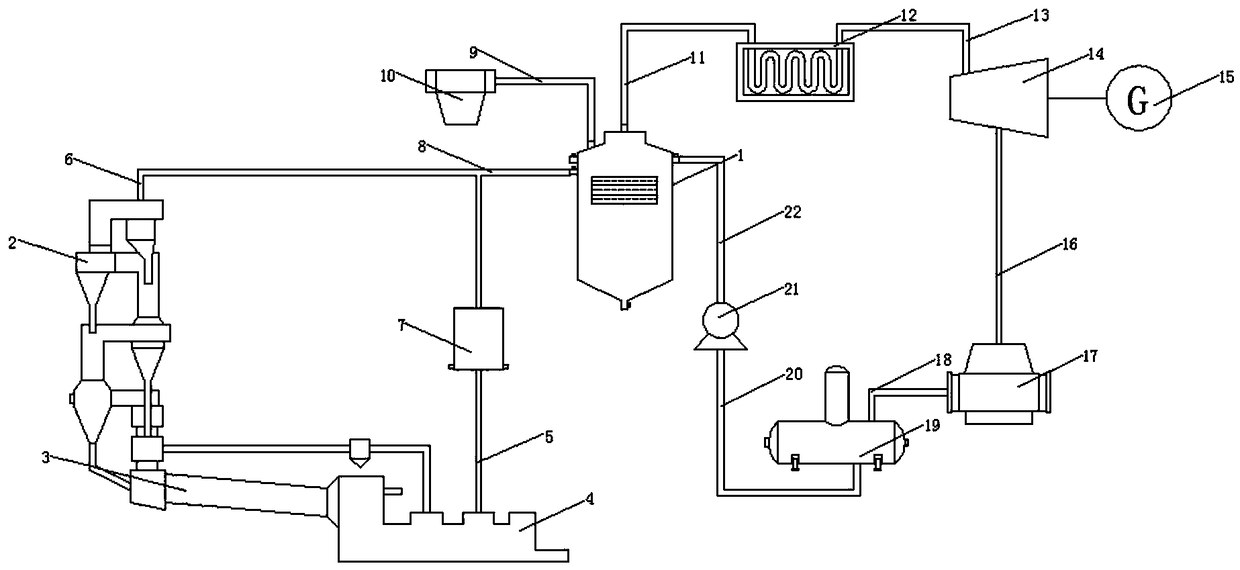

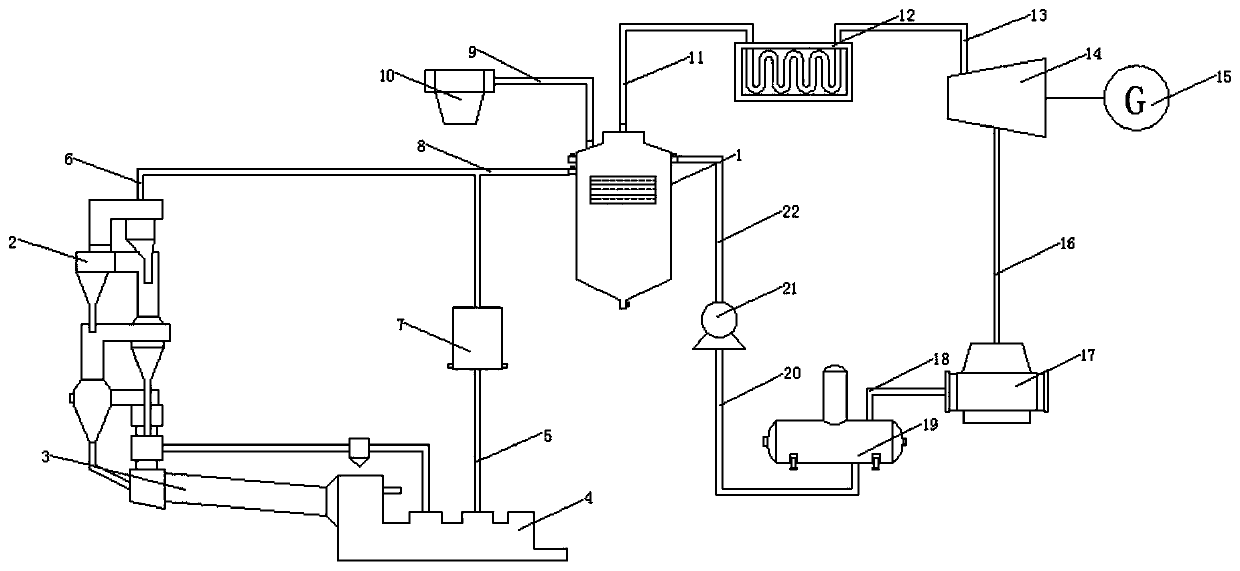

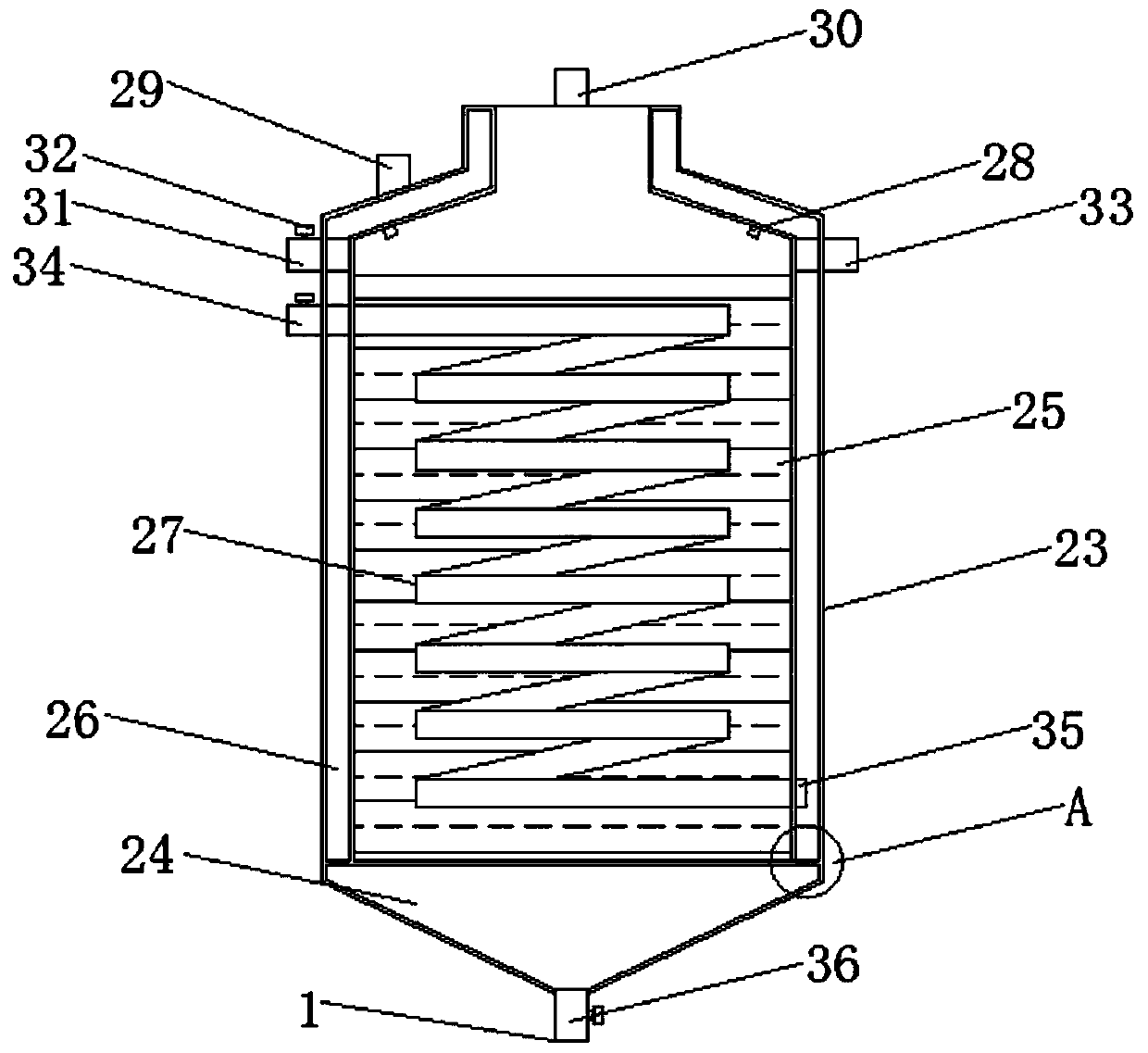

Cement kiln pure low temperature waste heat generator

ActiveCN109028980AGuaranteed to blockWhile blocking, it is also convenient for the rapid fall of clinker particlesIncreasing energy efficiencyClinker productionEngineeringCement kiln

The invention discloses a cement kiln pure lowtemperature waste heat generator.One end of a preheater is provided with a rotary kiln, one end of the rotary kiln is provided with a cooling machine, oneend of the cooling machine is fixedly connected with a waste gas pipe of a pit head, the middle of the waste gas pipe of the pit head is provided with a settling box, and inclined blocks are arrangedon both sides of the bottom end of the settling box. Bafflesare installed on both sides of the top of the inclined block, and a cellar tail exhaust pipe is fixedly connected with one end of a cellarhead exhaust pipe, and a mixed exhaust pipe is fixedly connected with one end of the cellar tail exhaust pipe, and a generator body is installed at one end of the mixed exhaust pipe. The top of the generator body is provided with a tank body, the inside of the tank body is provided with a steam generating chamber, and the bottom of the tank body is equipped with a dust exhausting bucket. Accordingto the a cement kiln pure lowtemperature waste heat generator, the bottom end of the bafflesareprovided with a plurality of elastic bumpswhich play a certain buffering role and can weaken the impactof waste gas from the pit head containing clinker particles on the baffles in the flow process, is simple and practical, service life of the baffles are prolonged, and later maintenance cost is reduced.

Owner:SICHUAN MIANZHU AODONG CEMENT CO LTD

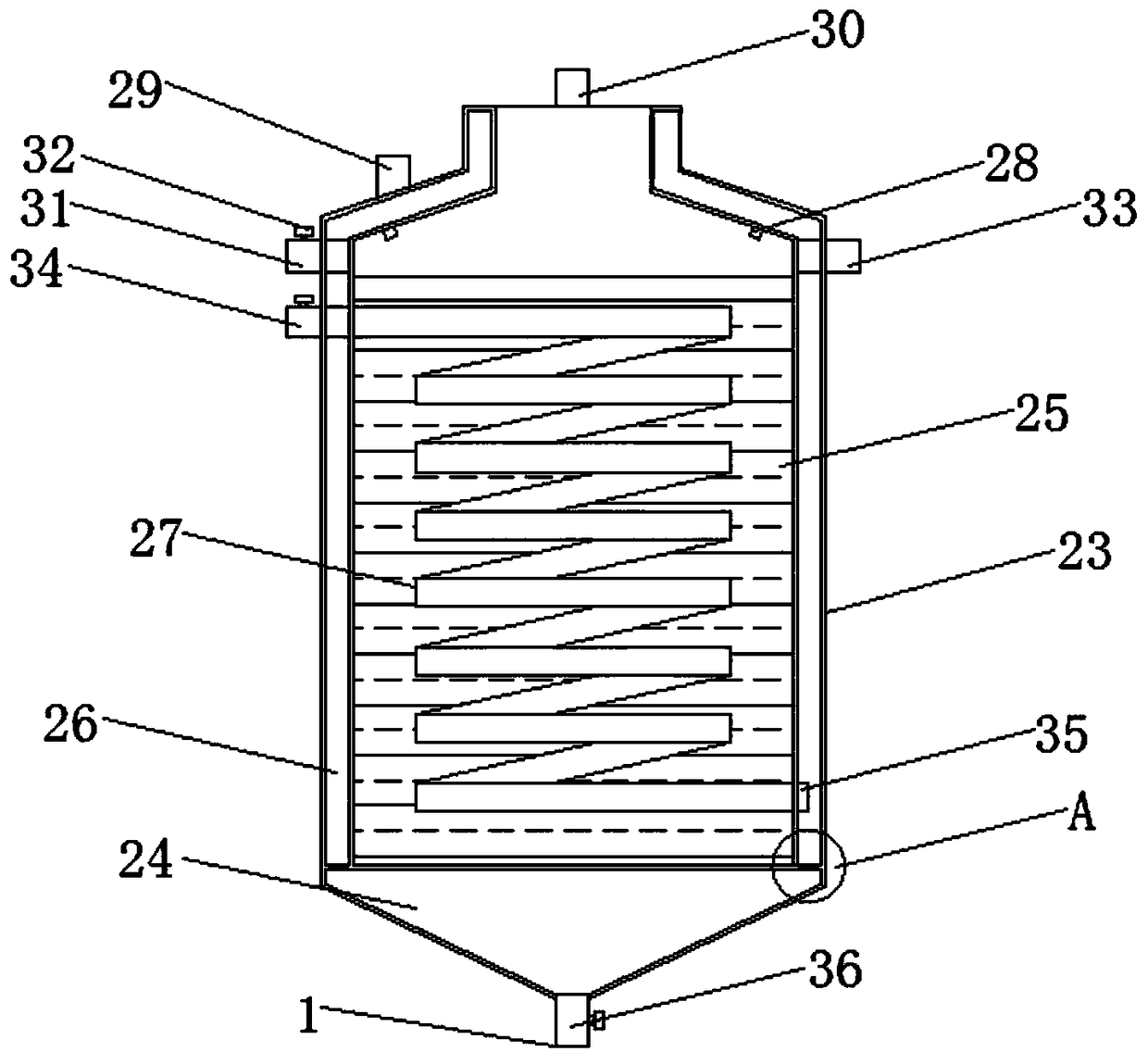

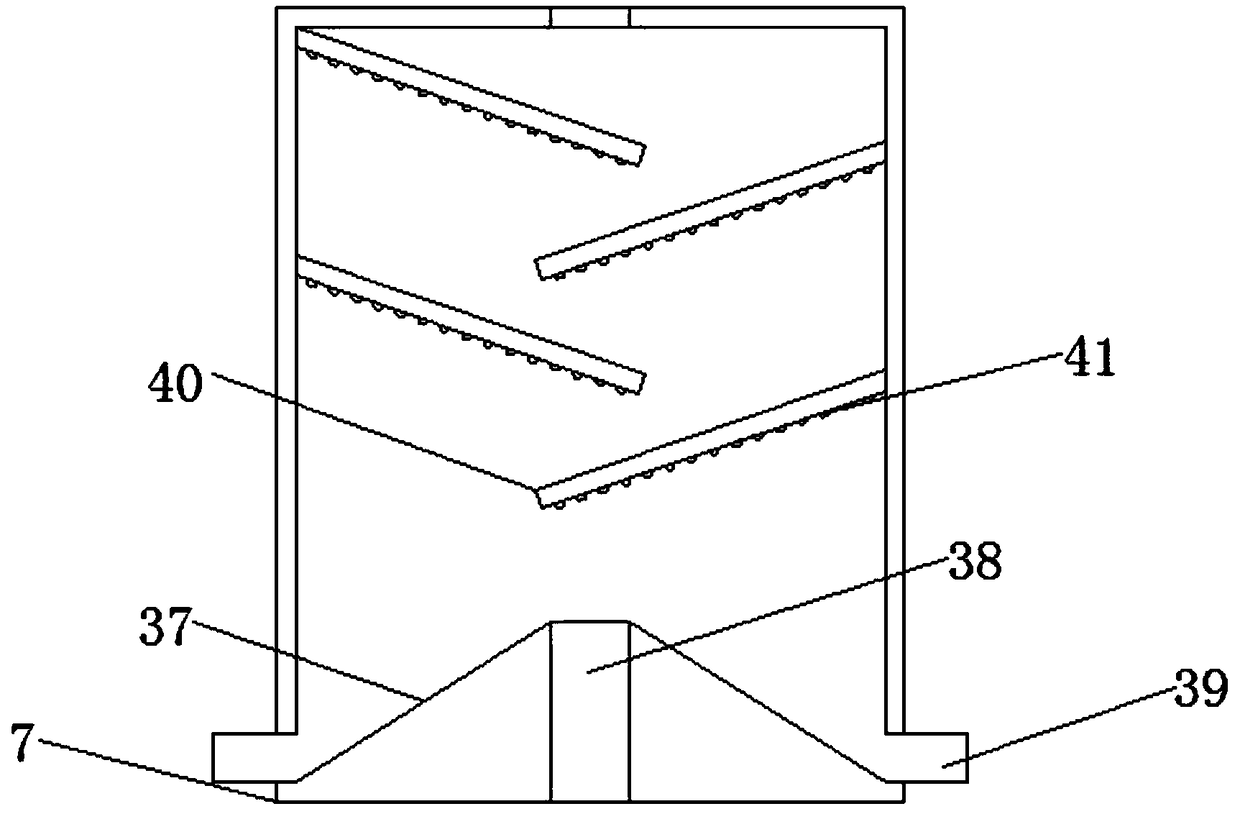

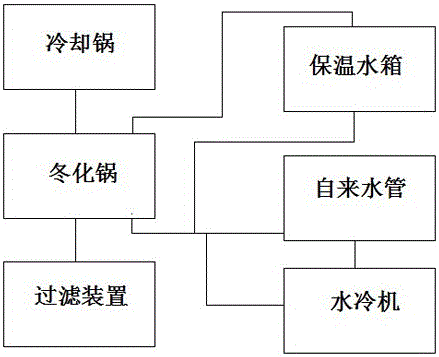

Camellia seed oil winterization method and device

InactiveCN106566652AHigh yieldUniform and sufficient precipitationFatty-oils/fats refiningWater coolingWinterization

The invention discloses a camellia seed oil winterization method. The camellia seed oil winterization method comprises the following steps that (1), camellia seed oil treated through deodorization is placed in a cooling tank to be naturally cooled to 40-45 DEG C; (2), the cooled camellia seed oil is placed in a winterization pot and is cooled and winterized with indoor domestic tap water, wherein the winterization temperature is 6-10 DEG C, stirring and cold water cooling are conducted firstly, when the color of the oil in the pot is earth color, stirring and cooling are stopped, crystal growing is conducted for 5-7 days until floccules in the pot are in a snowflake shape, and then the filtering step is executed. The invention further discloses a camellia seed oil winterization device.

Owner:永兴泰宇茶油有限公司

Liquid crystal display device and manufacturing method thereof

Owner:CHANGSHA HKC OPTOELECTRONICS CO LTD

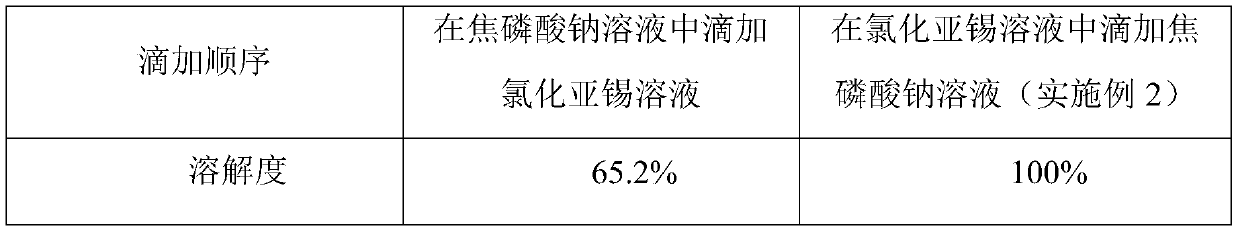

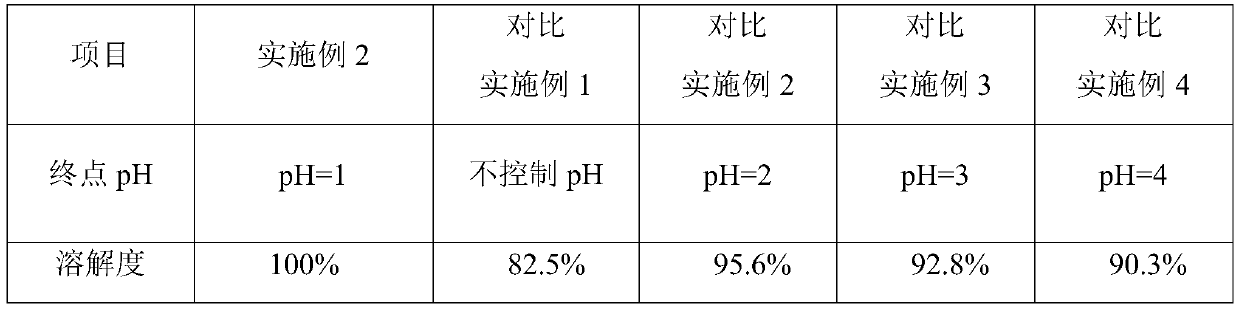

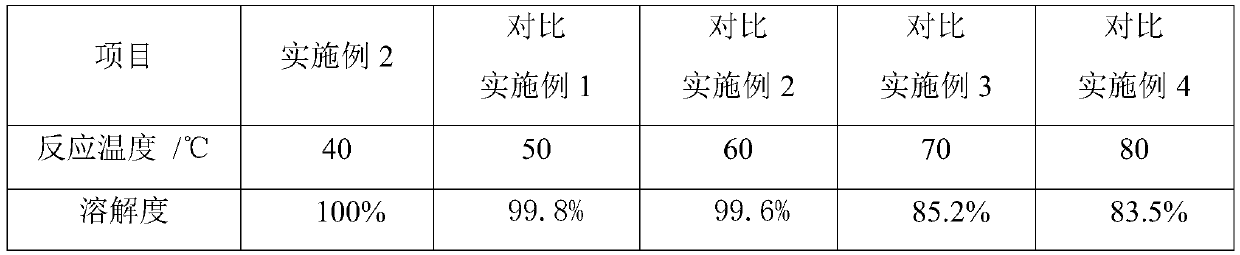

Method for improving solubility of stannous pyrophosphate

ActiveCN110155975AAvoid Yield ImpactImprove solubilityPhosphorus compoundsSolubilityReaction temperature

The invention discloses a method for improving solubility of stannous pyrophosphate. The method comprises the following steps: with a sodium pyrophosphate solution and a stannous chloride solution asraw materials, carrying out a metathesis reaction under a certain condition, and carrying out centrifugal spin-drying, washing, drying and packaging on the reaction product. According to the method disclosed by the invention, the adding sequence is skillfully changed, specifically, the sodium pyrophosphate solution is added into the stannous chloride with added dilute hydrochloric acid, so that the whole reaction system is under an acidic condition; and meanwhile, through limit of reasonable pH value, reaction temperature, liquid adding speed and heat preservation time, generation of insolublesubstance Sn(OH)2 and Sn(OH)4 can be avoided, influence of tin hydrolysis on the product yield can be balanced when the pH value is greater than 1, and solubility of the product is also improved under the condition that a high-purity product is obtained.

Owner:GUANGXI NORMAL UNIV OF SCI & TECH

A pure low temperature waste heat generator for cement cellar

ActiveCN109028980BGuaranteed to blockConvenient whereaboutsIncreasing energy efficiencyClinker productionEngineeringCement kiln

The invention discloses a cement kiln pure lowtemperature waste heat generator.One end of a preheater is provided with a rotary kiln, one end of the rotary kiln is provided with a cooling machine, oneend of the cooling machine is fixedly connected with a waste gas pipe of a pit head, the middle of the waste gas pipe of the pit head is provided with a settling box, and inclined blocks are arrangedon both sides of the bottom end of the settling box. Bafflesare installed on both sides of the top of the inclined block, and a cellar tail exhaust pipe is fixedly connected with one end of a cellarhead exhaust pipe, and a mixed exhaust pipe is fixedly connected with one end of the cellar tail exhaust pipe, and a generator body is installed at one end of the mixed exhaust pipe. The top of the generator body is provided with a tank body, the inside of the tank body is provided with a steam generating chamber, and the bottom of the tank body is equipped with a dust exhausting bucket. Accordingto the a cement kiln pure lowtemperature waste heat generator, the bottom end of the bafflesareprovided with a plurality of elastic bumpswhich play a certain buffering role and can weaken the impactof waste gas from the pit head containing clinker particles on the baffles in the flow process, is simple and practical, service life of the baffles are prolonged, and later maintenance cost is reduced.

Owner:SICHUAN MIANZHU AODONG CEMENT CO LTD

Lower die blanking structure with scrap jumping prevention function

The invention discloses a lower die blanking structure with a scrap jumping prevention function. The lower die blanking structure is characterized by comprising a blanking area and a scrap storage area positioned below the blanking area, the section of the blanking area is non-circular, the section of the scrap storage area is circular, and the section of the blanking area is smaller than that of the scrap storage area. The lower die blanking structure with the scrap jumping prevention function has the advantages that the lower die blanking structure is simple, is low in manufacturing cost, and can effectively prevent scraps from jumping out of a die surface, so that influence of scrap jumping to yield of products is avoided.

Owner:CHENGYEDE KUNSHAN COMM TECH

A method for rapidly multiplying vegetative propagation of fig seedlings of Masiyi Taofen

Owner:江苏龙山湖生物科技有限公司

A low-rank coal adiabatic pyrolysis device

InactiveCN104610990BAvoid Yield ImpactHigh purityDirect heating destructive distillationSpecial form destructive distillationInsulation layerRetention time

The invention relates to a low-rank coal adiabatic pyrolysis device which is composed of a charging hopper, an adiabatic drying chamber, an adiabatic dry distillation chamber and a coke quenching tank which are communicated in sequence, wherein the adiabatic drying chamber is the same as the adiabatic dry distillation chamber in diameter and size; gas insulation layers which have the same temperature as the adiabatic drying chamber and the adiabatic dry distillation chamber are respectively arranged on the peripheries; outer insulation layers are respectively arranged on the peripheries of the adiabatic drying chamber and the adiabatic dry distillation chamber. The low-rank coal adiabatic pyrolysis device is simple in structure and good in adiabatic effect, coal materials move downwards by means of gravity, tail gas generated in the drying process and tail gas generated in the pyrolysis process are separately processed, the retention time of discharge quantity is easy to control, and the air inlet temperature is basically consistent with the center temperature of a reactor, so that the pyrolysis efficiency of a coal pyrolysis reactor is greatly improved.

Owner:TAIYUAN UNIV OF TECH

Double rotary tillage proportional layered fertilization wide seedling width precision seeder

ActiveCN105557102BImprove blending uniformityImprove the quality of field returnSpadesSaving energy measuresAnti jammingTerra firma

The invention relates to a broad-seedling-width precision sowing machine with functions of double rotary tillage and proportional layering fertilization. The precision sowing machine comprises a suspended rack, a gearbox, a double-shaft rotary tillage device assembly, an anti-jamming spiral land leveler, a proportional layering fertilization device assembly, a rolling cage harrow, a broad-seedling-width strip sowing device assembly, a cylindrical heavy roller, and a proportional layering fertilization and precision sowing intelligent control system; and the precision sowing machine can sequentially finish operations in links of double rotary tillage for land preparation, spiral blade land leveling for jamming prevention, proportional layering fertilization, land leveling and rolling before sowing, broad-seedling-width precision sowing, rolling after sowing and the like in one time. According to the precision sowing machine, the broad-seedling-width sowing can be realized and a twice throwing and unique multilayer comb strip decentralizing and seed uniformizing structure is adopted, so that seeds can be uniformly distributed in a relatively broad seedling width (8-10cm) range and the space layout structure of seedlings is remarkably improved; and the relationship between a group and an individual is coordinated and a reasonable crop group is created, so that a solid foundation is laid for high yield.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

A kind of production technology of memantine hydrochloride

ActiveCN103965058BHigh yieldLess side effectsOrganic compound preparationAmino compound preparationMemantine HydrochlorideHydrolysis

The invention belongs to the technical field of medicine, in particular to a production process of memantine hydrochloride. The production process of memantine hydrochloride of the present invention comprises the following steps: 1-bromo-3,5-dimethyladamantane reacts with acetonitrile under the action of concentrated sulfuric acid to obtain 1-acetylamino-3,5 -Dimethyladamantane, the temperature of acetylamination reaction is 5-10°C; 1-acetamido-3,5-dimethyl and polyhydric alcohol without ether bond undergo hydrolysis reaction under alkaline conditions to obtain 1-amino-3,5-dimethyladamantane; 1-amino-3,5-dimethyladamantane is acidified with hydrochloric acid and recrystallized to obtain high-purity memantine hydrochloride. The production process of memantine hydrochloride of the present invention is based on the existing synthesis process, by controlling process parameters and changing process conditions, the product yield of memantine hydrochloride is improved.

Owner:CHENGDU YILUKANG MEDICAL TECH & SERVICE

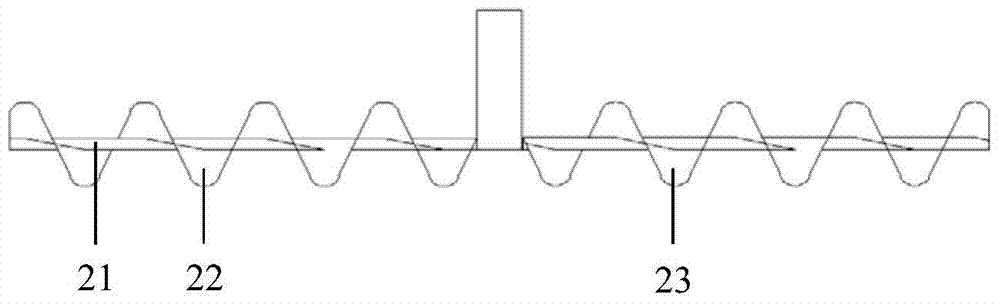

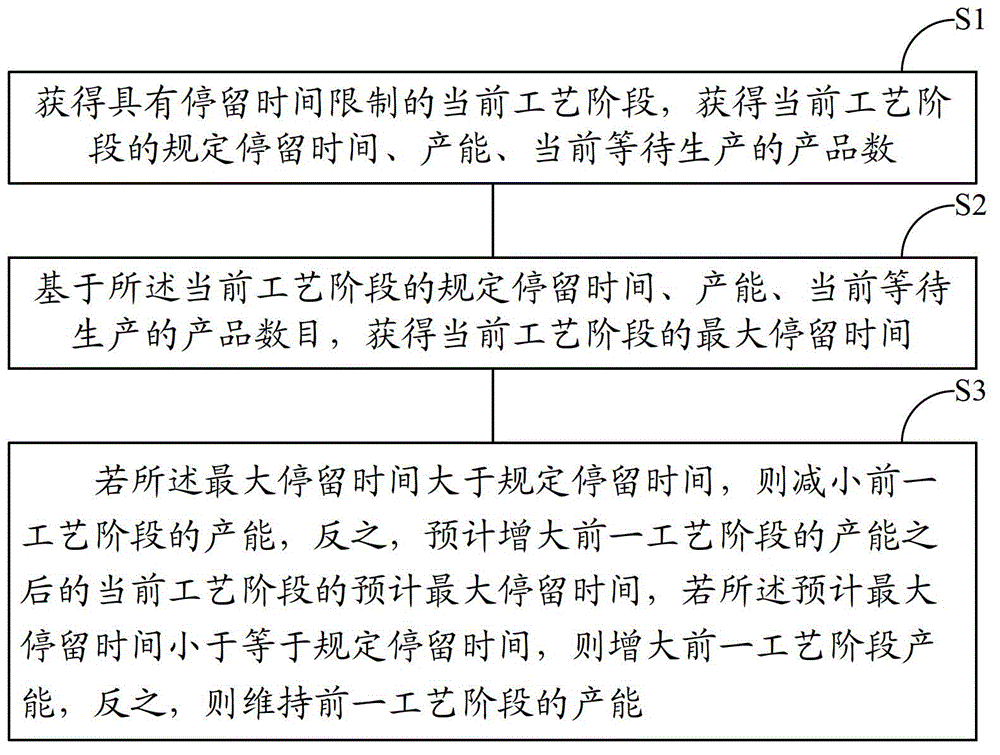

Method and system for adjusting capacity of a process stage with residence time limitation

ActiveCN103227128BRealize automatic adjustmentAvoid Yield ImpactSemiconductor/solid-state device manufacturingSystem capacityResidence time

The invention provides a method and a system for adjusting capacity of process stages with residence time limitation. The method comprises the steps that the current process stage with the residence time limitation is obtained; specified residence time, the capacity and the number of the current products waiting for production of the current process stage are obtained; the maximum residence time of the current process stage is obtained; if the maximum residence time is greater than the specified residence time, the capacity of the previous process stage is reduced; contrarily, the predicted maximum residence time of the current process stage after the capacity of the previous process stage is increased is predicted; if the predicted maximum residence time is less than or equal to the specified residence time, the capacity of the previous process stage is increased; and contrarily, the capacity of the previous process stage is maintained. According to the method and the system, the capacity of the relevant process stages can be adjusted automatically, and the capacity among the process stages is balanced, so that a yield is prevented from being influenced, and mutual benefits of the capacity and the quality are achieved.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

A kind of method for preparing phenylpyruvate

ActiveCN111118074BAvoid Yield ImpactQuality improvementTransferasesMicroorganism based processesEscherichia coliPhenylpyruvic acid

The invention discloses a method for preparing phenylpyruvate. First, the transaminase gene ata is inserted into the pET28a plasmid to construct transaminase recombinant Escherichia coli cells, and then the E. coli cells expressing the transaminase gene are induced and expressed, and finally the large intestine expressing the transaminase gene is Bacillus thallus and L-phenylalanine carry out catalytic reaction to obtain α-phenylpyruvate; The concentration of the Escherichia coli thallus expressing transaminase gene is 1.5-2.5g / L, and the concentration of L-phenylalanine is 4-phenylalanine 8g / L. The method of the present invention adopts optimal induction conditions combined with optimal catalytic conditions, avoiding the influence of pH, temperature, time, substrate concentration and bacterial cell concentration on the yield of phenylpyruvate, and the substrate conversion rate reaches 91%. Obtain high-quality and high-yield phenylpyruvate.

Owner:TAIZHOU UNIV

A kind of day lily planting method

ActiveCN111955292BGuaranteed not to affect each otherAvoid damageAgriculture gas emission reductionPlant cultivationHuskHemerocallis citrina

Owner:王锦亮 +1

Method for preparing phenylpyruvic acid

ActiveCN111118074AAvoid Yield ImpactQuality improvementTransferasesMicroorganism based processesEscherichia coliPhenylpyruvic acid

The invention discloses a method for preparing phenylpyruvic acid. The method comprises the following steps: firstly, inserting a transaminase gene ata into a pET28a plasmid to construct a transaminase recombinant escherichia coli bacterium, secondly, performing induction expression so as to obtain an escherichia coli bacterium expressing a transaminase gene, and finally performing a catalysis reaction on the escherichia coli bacterium expressing the transaminase gene and L-phenylalanine, so as to obtain alpha-phenylpyruvic acid, wherein the concentration of the escherichia coli bacterium expressing the transaminase gene is 1.5-2.5g / L, and the concentration of the L-phenylalanine is 4-8g / L. By adopting the method, optimal induction conditions are combined with optimal catalysis conditions,the influence of multiple aspects such as pH values, temperatures, time, substrate concentrations and bacterium concentrations upon the yield of the phenylpyruvic acid can be avoided, the substrate conversion rate is up to 91%, and phenylpyruvic acid of high quality and high yield can be obtained.

Owner:TAIZHOU UNIV

Day lily planting method

ActiveCN111955292AGuaranteed not to affect each otherAvoid damageAgriculture gas emission reductionPlant cultivationPlant rootsHusk

The invention relates to a day lily planting method. The planting method includes the following steps: step one, performing planting and group planting in large and small rows, putting planting containers planted with day lily into holes, wherein planting cavities are formed in the shells of the planting containers, the bottoms inside the planting cavities are provided with water retaining agent cushion layers, and a part of the shells which are higher than the water retaining agent cushion layers are root protruding parts; and after planting single day lily in the cushion layers, filling thecushion layers with nutrient soil, and placing the planting containers into the holes after two or more planting containers of which root protruding parts are not opposite to each other are fixedly connected; step two, performing field management and protection, performing shallow intertillage before seedling emergence in spring, and performing shallow intertillage to keep soil moistening before bolting and flowering; step three, performing harvesting at the right time, and picking the day lily 1-2 hours before blooming; and step four, timely transplanting and selecting robust and disease-freeplants, cutting the plants in the planting cavities along the inner walls of the planting containers to take out as seedlings, and cutting long fleshy roots to transplant. Through the arrangement ofthe planting containers, the plants can be respectively planted and independently treated, so that damage to plant roots by ramet can be avoided.

Owner:王锦亮 +1

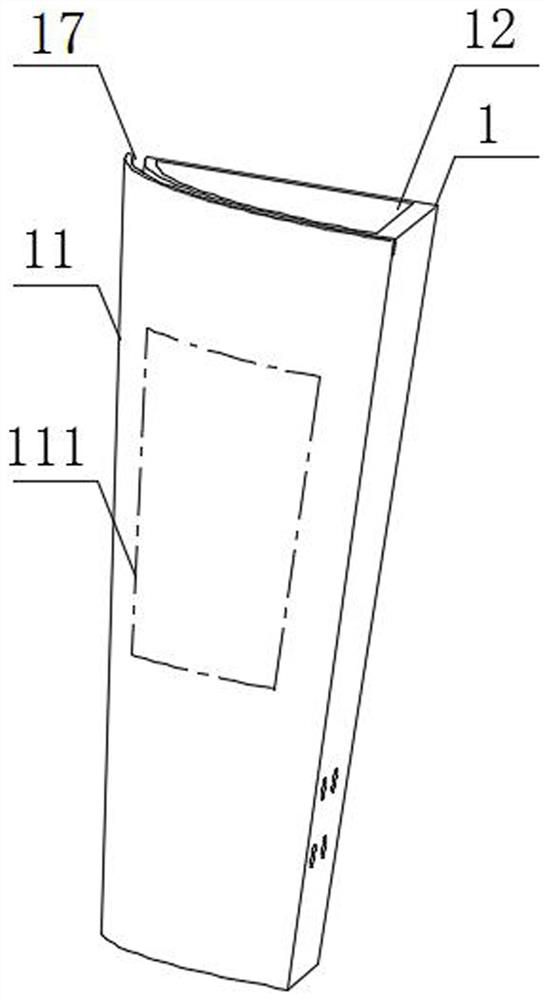

Industrial production method for preparing penicillin sulfoxide by continuously oxidizing penicillin

ActiveCN113214292AEasy to operateSimplify cumbersome operationsOrganic chemistryPenicillin G sulfoxideReaction temperature

The invention discloses an industrial production method for preparing penicillin sulfoxide by continuously oxidizing penicillin, and belongs to the field of pharmaceutical chemicals; a continuous reaction method is adopted, a penicillin solution and peracetic acid or other oxidants simultaneously flow into a mixer or a microreactor according to a certain proportion, and a penicillin sulfoxide solution is obtained by reaction at high temperature and in short time; the method can be used for an oxidation process of a process for preparing penicillin sulfoxide by taking penicillin fermentation liquor, filtrate, BA, RB, penicillin industrial salt and the like as initial raw materials, and solves the problem that the reaction temperature and the reaction time are influenced by mass transfer and low heat transfer efficiency of batch reaction; therefore, the problems of poor reaction liquid quality and low reaction yield are solved, and the yield of penicillin sulfoxide is high.

Owner:NORTH CHINA PHARMA COMPANY

Low-order coal heat insulation pyrolysis device

InactiveCN106753493AImprove pyrolysis efficiencySimple structureSpecial form destructive distillationCharging devicesCoal pyrolysisQuenching

The invention relates to a low-order coal heat insulation pyrolysis device. The low-order coal heat insulation pyrolysis device is formed by sequentially communicating a material charging hopper, a heat insulation drying chamber, a heat insulation dry distillation chamber, and a coke quenching tank, wherein the diameter of the heat insulation drying chamber is the same with the diameter of the heat insulation dry distillation chamber; gas heat insulation layers are respectively arranged at the periphery and have the same temperature with the heat insulation drying chamber and the heat insulation dry distillation chamber; outer heat insulation layers are respectively arranged at the peripheries of the heat insulation drying chamber and the heat insulation dry distillation chamber. The low-order coal heat insulation pyrolysis device has the advantages that the structure is simple, the heat insulation effect is good, and the coal is discharged under the gravity action; the tail gas produced in the drying process is separated from the tail gas produced in the pyrolysis process, the material discharging amount and the dwelling time can be easily controlled, the air intake temperature is basically uniform with the center temperature of the reactor, and the pyrolysis efficiency of a coal pyrolysis reactor is greatly improved.

Owner:曹淅

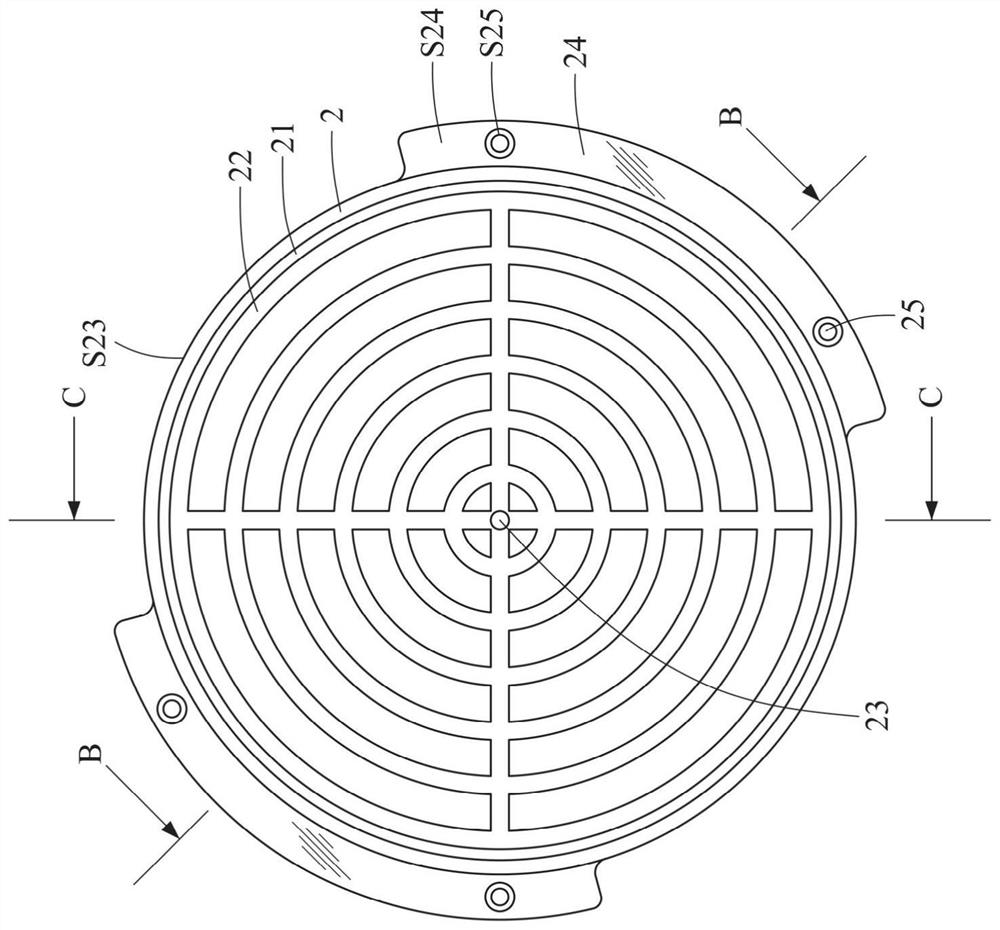

Precise ceramic workbench with quartz base

PendingCN113547225AAvoid destructionAvoid Yield ImpactLaser beam welding apparatusPhysical chemistryEngineering

The invention relates to a precise ceramic workbench which comprises a multi-through-hole precise ceramic disc and a quartz base. The multi-through-hole precision ceramic plate is provided with multiple holes, and the upper surface of the multi-through-hole precision ceramic plate is a workpiece adsorption surface. The multi-through-hole precision ceramic plate is clamped on the quartz base. At least part of the surface of the quartz base is polished, so that the quartz base is prevented from being damaged by laser energy.

Owner:HOMMER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com