A kind of method for preparing phenylpyruvate

A technology of phenylpyruvate and bacteria, applied in the biological field, can solve problems such as the influence of phenylpyruvate yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preparing phenylpyruvate, the steps are:

[0041] (1) Construction of transaminase recombinant Escherichia coli strain: extract the transaminase gene ata in the Arthrobacter sp. Insert the double digested product into the pET28a plasmid to obtain the pET28a plasmid linked with transaminase, named pET28a-ata, and finally transform pET28a-ata into BL21 competent cells to obtain transaminase recombinant E. coli cells, named BL21(DE3) / pET28a-ata;

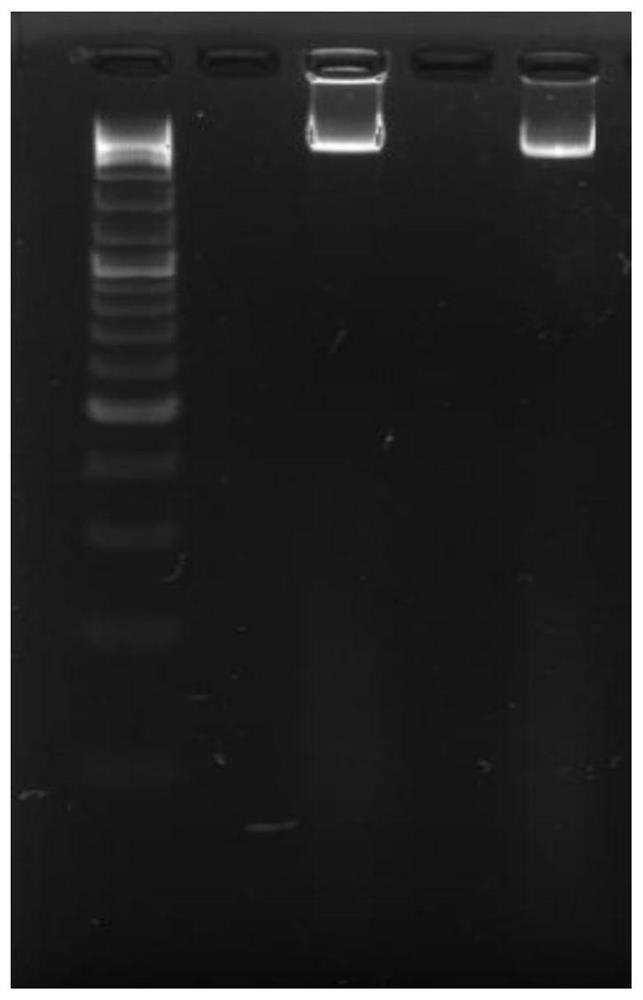

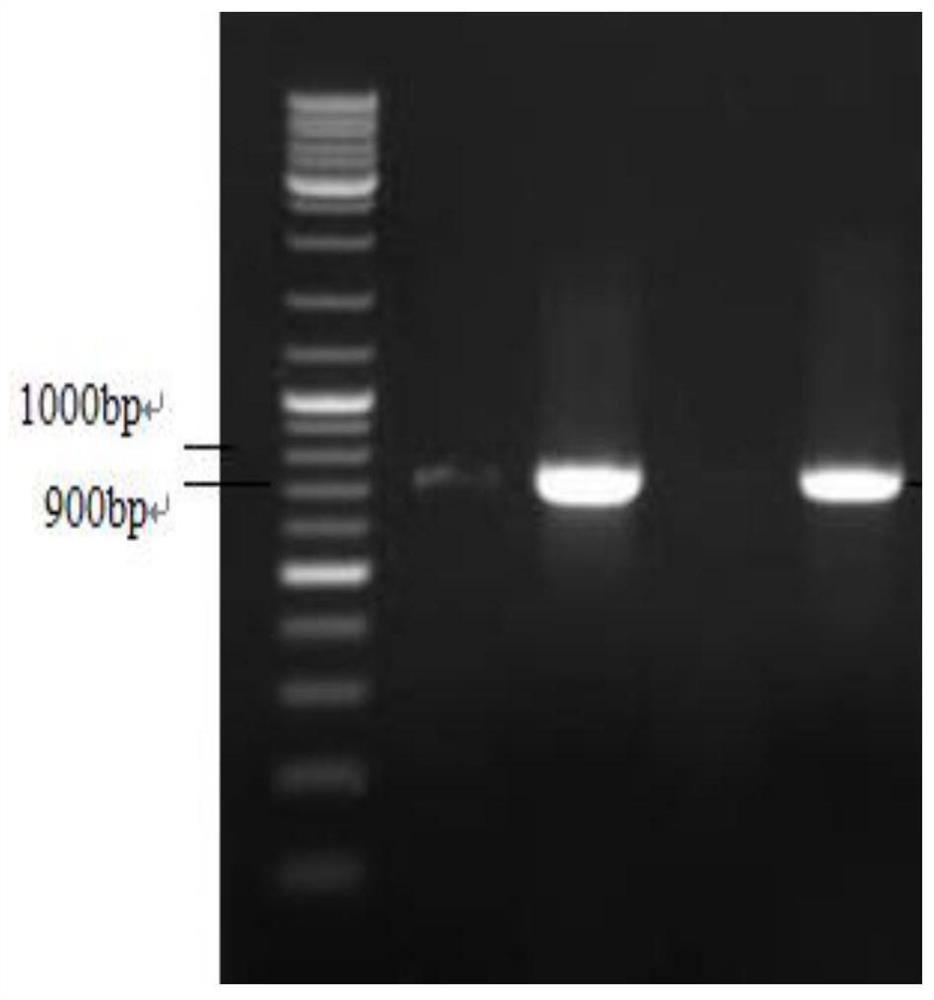

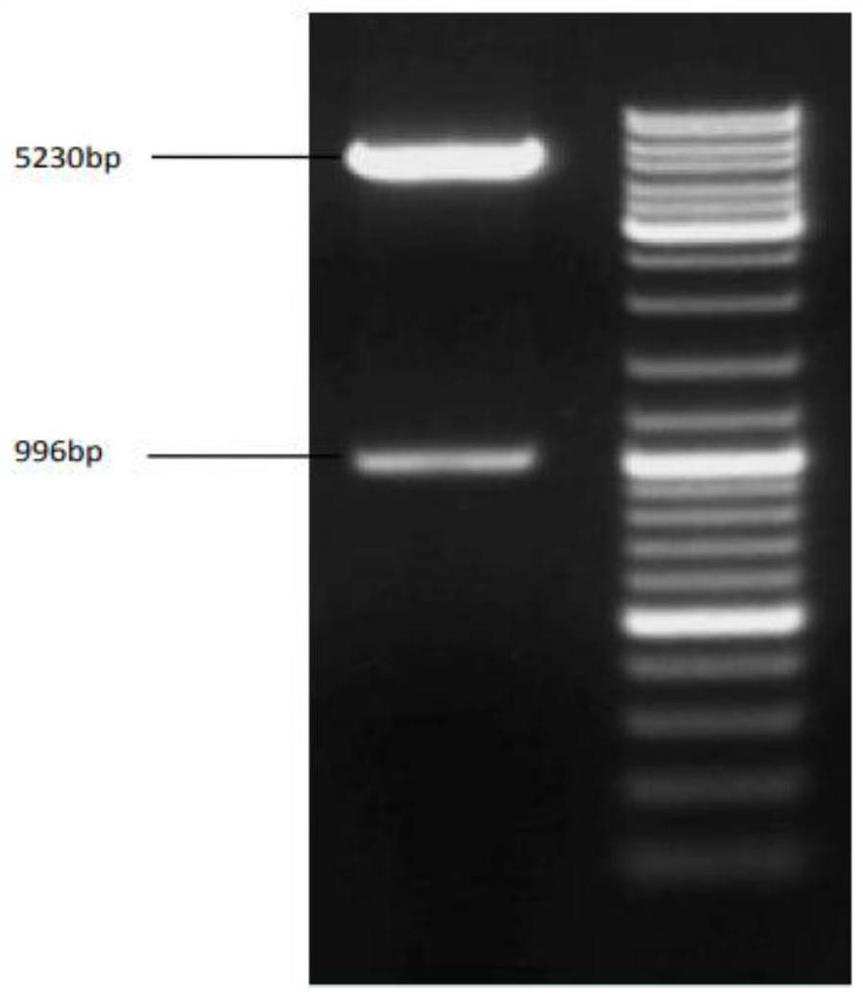

[0042] The plasmid was extracted from BL21(DE3) / pET28a-ata and verified by electrophoresis and sequencing after double enzyme digestion. figure 1 and figure 2 It showed that the genome was successfully extracted and PCR amplified to transaminase gene. The plasmid extracted from BL21(DE3) / pET28a-ata was digested with NcoI and XhoI to obtain two bands of 996bp and 5230bp (such as image 3 shown), are the lengths of pET28a and the target gene, respectively, and the results show that the recombinant plasmid pET28a-...

Embodiment 2

[0048] A method for preparing phenylpyruvate, the steps are:

[0049] (1) Construction of transaminase recombinant Escherichia coli strain: extract the transaminase gene ata in the Arthrobacter sp. Insert the double digested product into the pET28a plasmid to obtain the pET28a plasmid linked with transaminase, named pET28a-ata, and finally transform pET28a-ata into BL21 competent cells to obtain transaminase recombinant E. coli cells, named BL21(DE3) / pET28a-ata;

[0050] (2) Induced expression: BL21(DE3) / pET28a-ata was cultured on a shaker at 37°C at a rate of 100rpm / min, when the cell OD 600 When the concentration is 0.5, add IPTG with a final concentration of 0.1mmol / L, induce the reaction at 30°C for 6h, centrifuge at 8000rpm / min for 3min, and collect the cells to obtain Escherichia coli cells expressing the transaminase gene.

[0051] (3) Catalytic reaction: Escherichia coli cells expressing transaminase gene, L-phenylalanine and α-ketoglutaric acid were added to PBS bu...

Embodiment 3

[0054] A method for preparing phenylpyruvate, the steps are:

[0055] (1) Construction of transaminase recombinant Escherichia coli strain: extract the transaminase gene ata in the Arthrobacter sp. Insert the double digested product into the pET28a plasmid to obtain the pET28a plasmid linked with transaminase, named pET28a-ata, and finally transform pET28a-ata into BL21 competent cells to obtain transaminase recombinant E. coli cells, named BL21(DE3) / pET28a-ata;

[0056] (2) Induced expression: BL21(DE3) / pET28a-ata was cultured on a shaker at 37°C at a speed of 500rpm / min, when the cell OD 600 When the concentration is 0.7, add IPTG with a final concentration of 0.8mmol / L, then induce the reaction at 22°C for 12h, centrifuge at 8000rpm / min for 3min, and collect the cells to obtain Escherichia coli cells expressing the transaminase gene.

[0057] (3) Catalytic reaction: Escherichia coli cells expressing transaminase gene, L-phenylalanine and α-ketoglutaric acid were added to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com