Method for improving solubility of stannous pyrophosphate

A technology of stannous pyrophosphate and solubility, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems that have not been found, high product purity and not necessarily solubility, and achieve the goal of saving materials and energy and improving solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

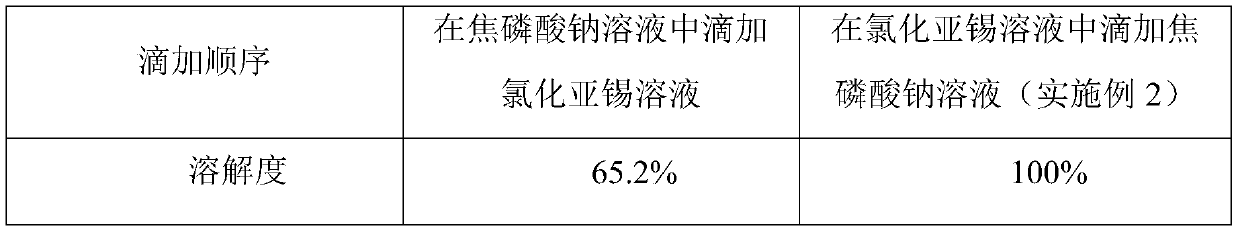

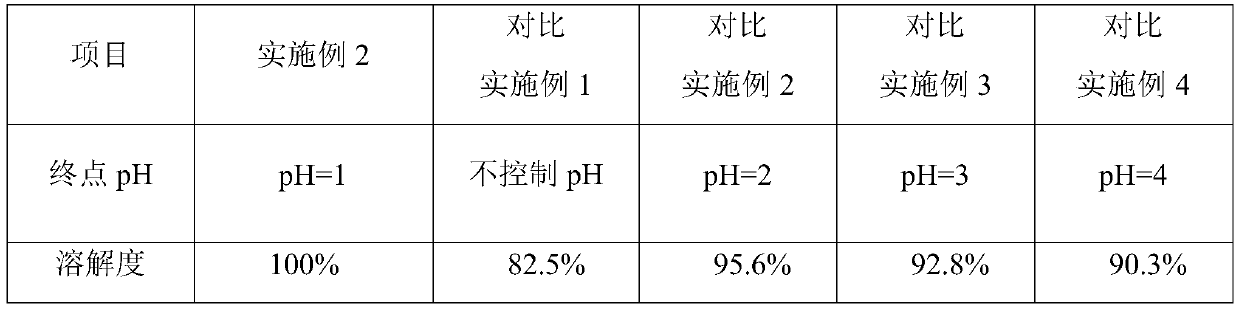

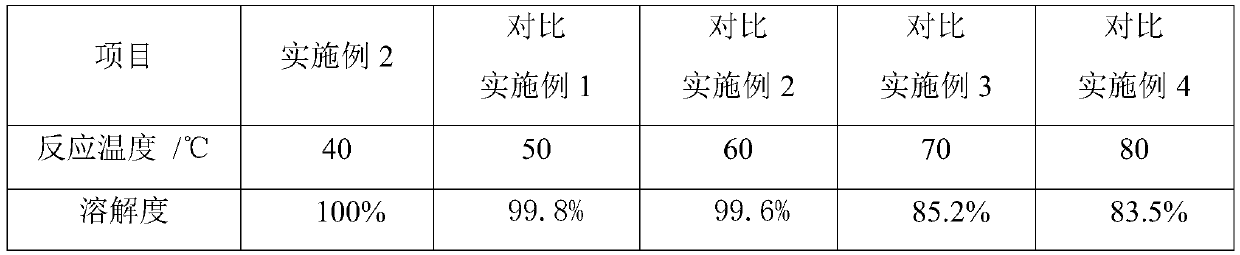

Method used

Image

Examples

Embodiment 1

[0030] Add 850mL of distilled water into a 1000mL container, heat to 40°C, add 45g of sodium pyrophosphate decahydrate, stir at 300r / min to dissolve, and keep warm. In a 2000mL reactor, add 230mL of 1mol / L dilute hydrochloric acid, add 50g of stannous chloride, stir and dissolve to form a solution. After the dissolution is complete, heat to 40°C and add sodium pyrophosphate solution dropwise to the reactor at a stirring speed of 80r / min at a rate of 10mL / min, monitor with a pH meter until pH=1, add coke dropwise At the same time as the sodium phosphate solution, 1 mol / L hydrochloric acid was added dropwise to control the pH=1. When the reaction solution became supernatant, the dropwise addition was stopped, and the reaction was continued for 40 minutes. Centrifuge at 600r / min to dry, wash with 120mL of water, and wash with 15mL of 95% alcohol to obtain stannous pyrophosphate solid. The solid was dried at 100° C. for 50 minutes under vacuum at -0.06 MPa to obtain a total of 40...

Embodiment 2

[0032] Add 517mL of distilled water into a 1000mL container, heat to 40°C, add 45g of sodium pyrophosphate decahydrate, stir at 400r / min to dissolve, and keep warm. In a 2000mL reactor, add 148mL of 2mol / L dilute hydrochloric acid, add 50g of stannous chloride, stir and dissolve to form a solution. After the dissolution is complete, heat to 40°C and add sodium pyrophosphate solution dropwise into the reactor at a stirring speed of 100r / min at a rate of 10mL / min, monitor with a pH meter until pH=1, add coke dropwise At the same time as sodium phosphate, 2 mol / L hydrochloric acid was added dropwise to control the pH=1, when the reaction solution was supernatant, the dropwise addition was stopped, and the incubation reaction was continued for 60 minutes. Centrifuge at 700r / min to dry, wash with 120mL of water, and wash with 15mL of 95% alcohol to obtain stannous pyrophosphate solid. The solid was dried at 150° C. for 40 minutes under vacuum at -0.08 MPa to obtain a total of 38 g...

Embodiment 3

[0034] Add 405mL of distilled water into a 1000mL container, heat to 50°C, add 45g of sodium pyrophosphate decahydrate, stir at 400r / min to dissolve, and keep warm. In a 2000mL reactor, add 105mL of 3mol / L dilute hydrochloric acid, add 50g of stannous chloride, stir and dissolve to form a solution. After the dissolution is complete, heat to 50°C and add sodium pyrophosphate solution dropwise into the reactor at a stirring speed of 200r / min at a rate of 20mL / min, monitor with a pH meter until pH=1, add coke dropwise At the same time as sodium phosphate, add 3 mol / L hydrochloric acid dropwise to control the pH=1, stop the dropwise addition when the reaction solution is supernatant, and continue to keep warm for 80 minutes. Centrifuge at 600r / min to dry, wash with 120mL of water, and wash with 15mL of 95% alcohol to obtain stannous pyrophosphate solid. The solid was dried at 200° C. for 30 minutes under vacuum at -0.07 MPa to obtain a total of 36 g of the product. The yield of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com