Method for manufacturing detection chip for measuring and checking numbers of particles and defects on chip

A defect count and chip detection technology, which is applied in the preparation of test samples, measurement devices, semiconductor/solid-state device testing/measurement, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

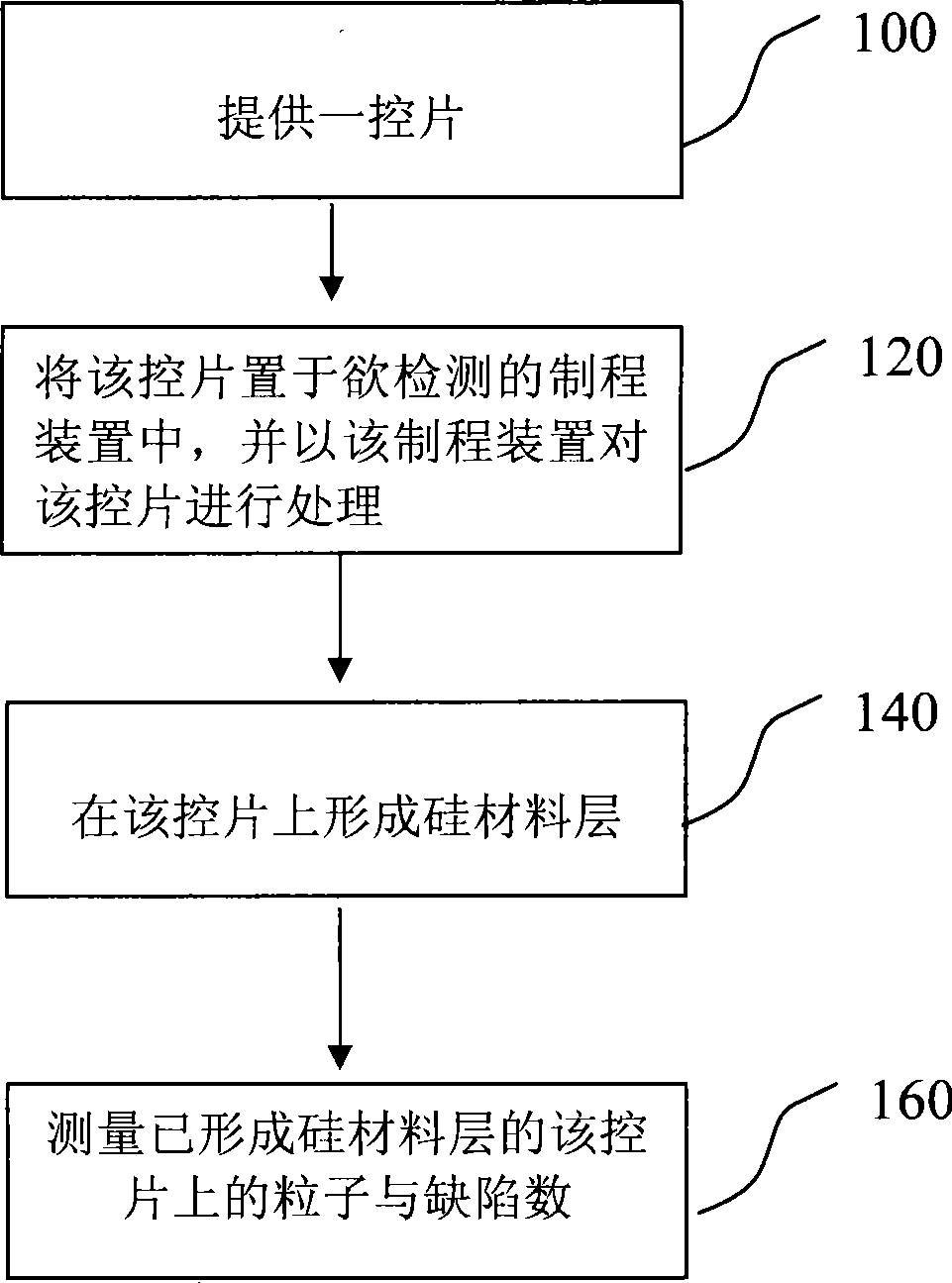

[0030] Please refer to figure 1 , figure 1 It is a flow chart of the steps of the method for detecting metal pollution and microparticles in a process device by using a control chip.

[0031] Step 100: Provide a control sheet such as a blank chip or a control sheet without graphics.

[0032] Step 120: Place the control piece in a process device to be tested, such as one of the machine equipment used in the processes of thin film deposition, dry etching, ion implantation and lithography, and compare the control with the process device The wafer is processed by one of the processes of thin film deposition, dry etching, ion implantation and lithography.

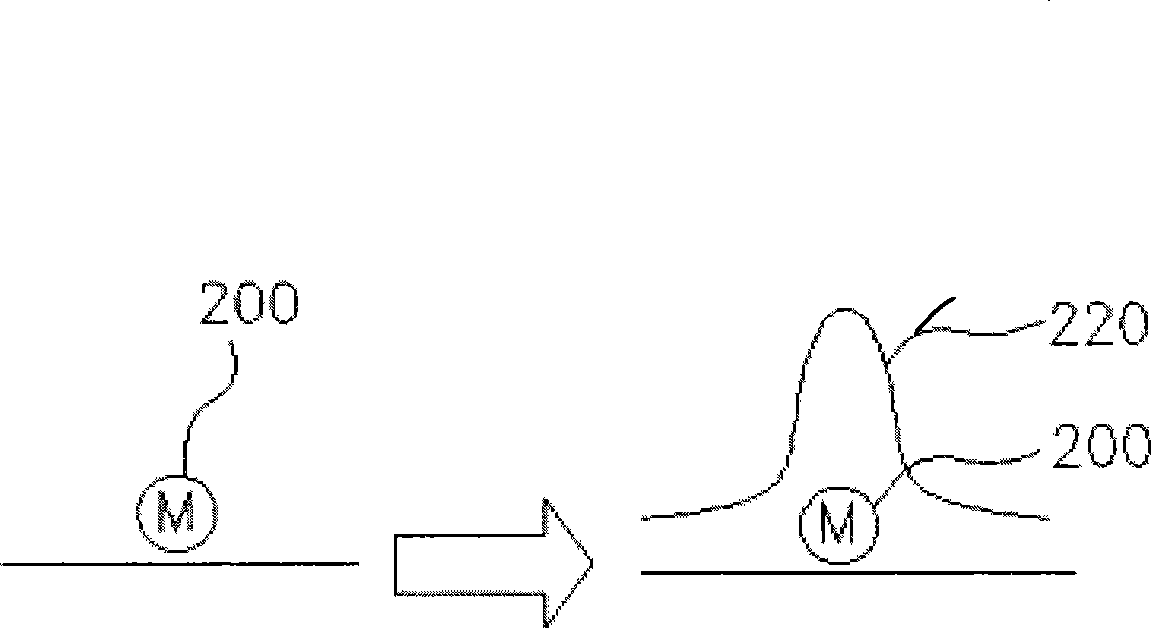

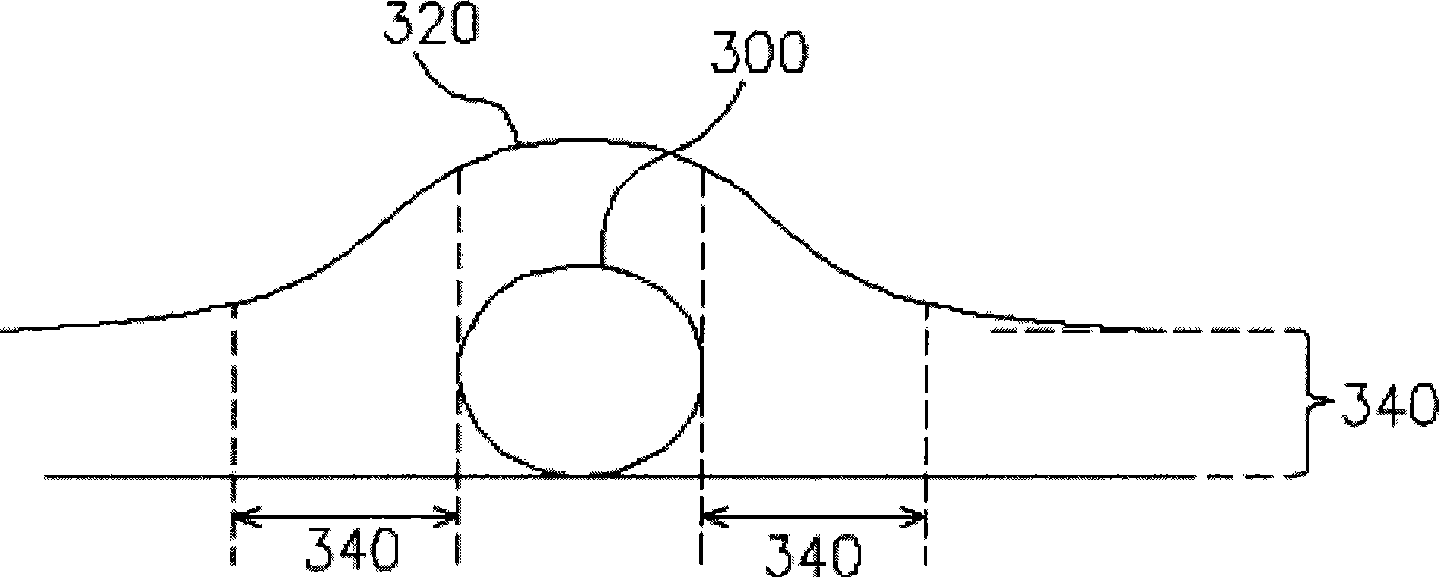

[0033] Step 140: Form a silicon material layer on the control chip (for example, the silicon material layer is polysilicon, amorphous silicon and epitaxial silicon), and the formation method of the silicon material layer can be, for example, chemical vapor deposition. When the silicon material layer is formed on the control ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com