A low-cost artificial sleeper

A low-cost, sleeper technology, applied in the field of railway bedding materials, can solve the problems of high economic and ecological costs, large consumption of wood, and ineffective shock absorption, etc., to achieve enhanced noise reduction and shock resistance, low cost, and light weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

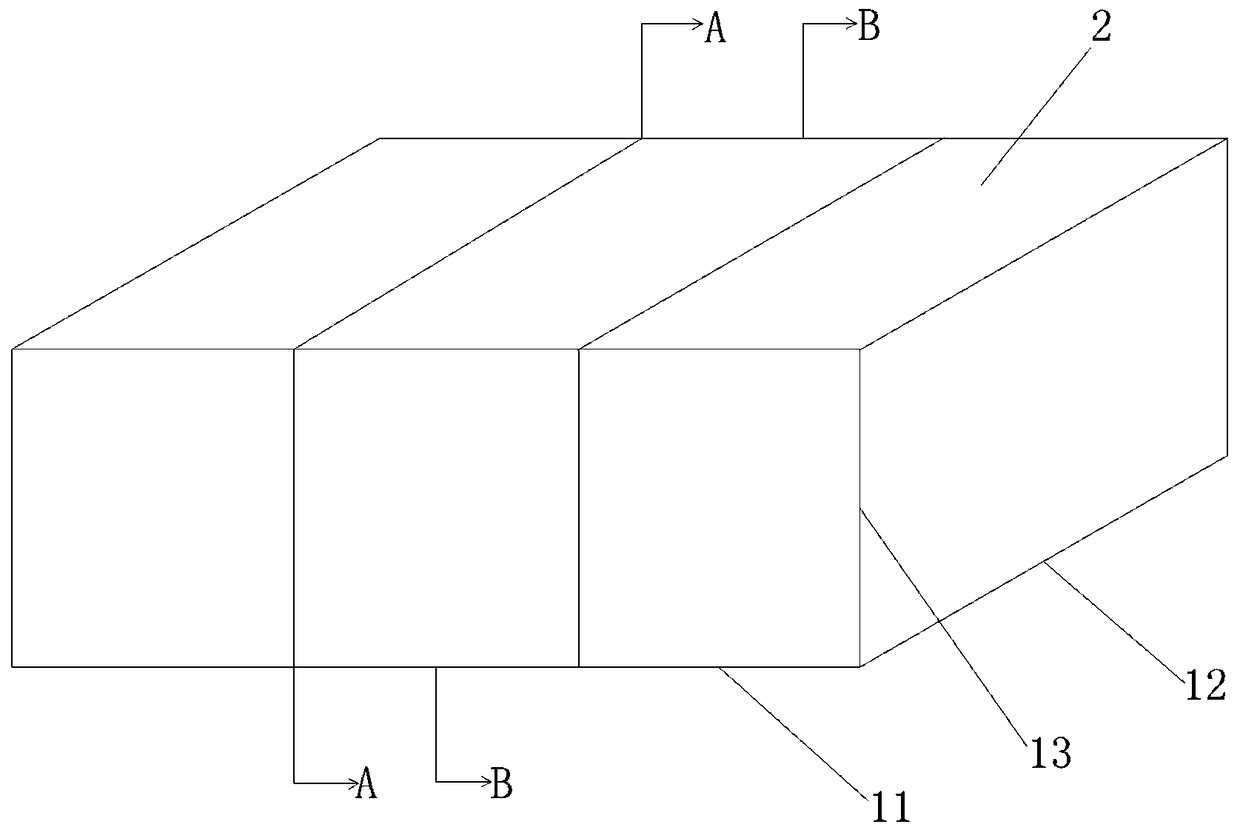

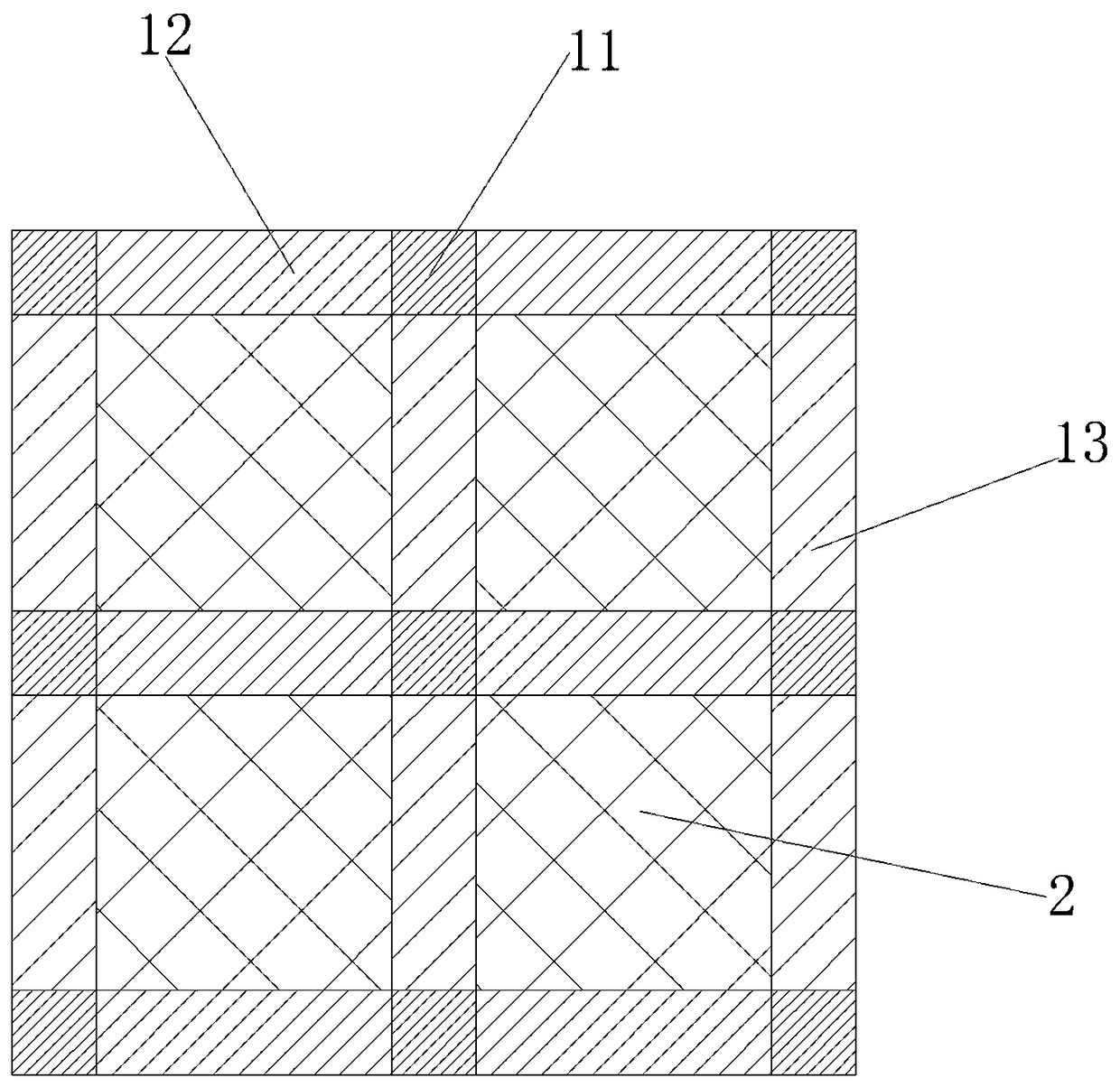

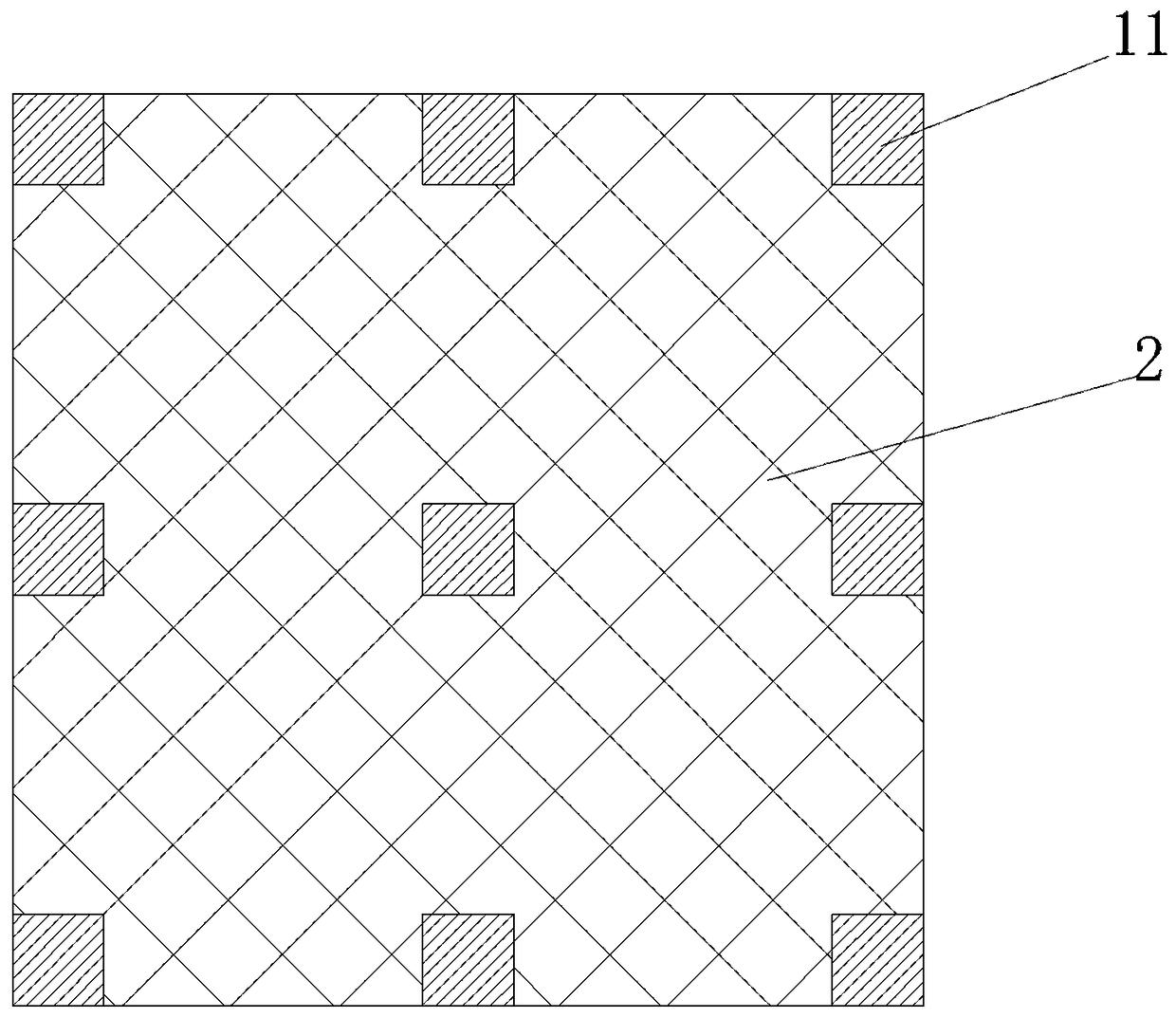

[0022] A low-cost artificial sleeper, which is formed by bonding a density board of 1-4 parts by weight and a polyurethane imitation wood with 6-9 parts by weight, wherein the density board is processed from crop straw; the polyurethane imitation wood contains parts by weight It is a mixture of 9 polyurethane A and polyurethane B, and 1 part by weight fiber. Polyurethane A and polyurethane B are both liquid. The ratio of polyurethane A and polyurethane B is any ratio, and the best ratio is 1:1; fiber length ≤5.0mm.

[0023] The preparation steps of low-cost artificial sleepers are:

[0024] a. Crushed, dried and compressed crop stalks into density board;

[0025] b. Stir and mix a mixture of 9 parts by weight of polyurethane A and polyurethane B and 1 part by weight of fibers evenly;

[0026] c. Put 1-4 parts by weight of the density board into the mold, and then pour 6-9 parts by weight of the polyurethane imitation wood mixture prepared in step b into a compression mold and foam.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com