An energy-dissipating beam-column joint for building steel structures

A technology of beam-column joints and steel structures, which is applied in the direction of building structures, buildings, building types, etc., can solve the problems of plastic damage of the main structure, occupying a large space, and difficult repairs, so as to reduce economic losses, simple structure, and effective obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

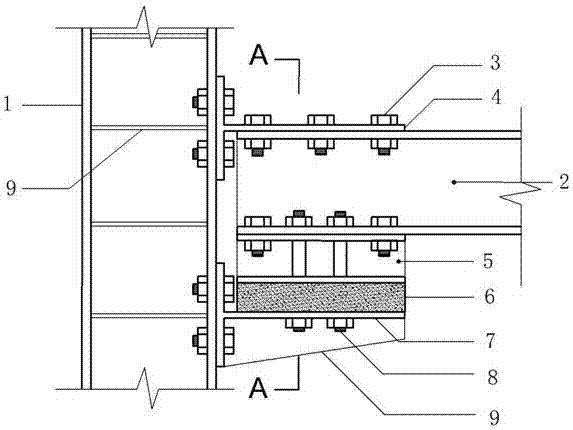

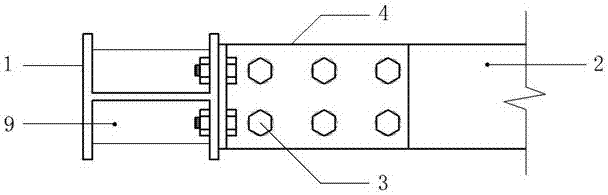

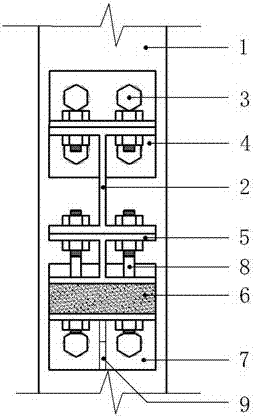

[0022] Embodiment 1: as Figure 1~4 As shown, it is an embodiment of an energy-dissipating beam-column node for building steel structures according to the present invention, including frame columns 1, frame beams 2, high-strength bolts 3, upper T-shaped connectors 4, small I-shaped steel connectors 5, Viscous friction damper 6, lower T-shaped connector 7, metal energy-dissipating rod 8, stiffener 9, in which two T-shaped connectors 4 and 7 are placed horizontally (the vertical web of the flange is horizontal); viscous The friction damper 6 has multiple layers, and dissipates energy through relative movement between layers; both ends of the metal energy dissipation rod 8 are threaded, and nuts can be screwed. Specific connection: the flange and web of the upper T-shaped connector 4 are respectively connected to the flange of the frame column 1 and the upper flange of the frame beam 2 through high-strength bolts 3, and at the same time, the lower flange of the frame beam 2 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com