Wall brick vertical surface mortar falling prevention structure of automatic mortaring machine and mortaring method of automatic mortaring machine

A technology for wall tiles and printing paste is applied to the vertical surface anti-dropping structure of wall bricks and the field of sizing, which can solve the problems of high price and high cost, and achieve the effects of convenient sizing, simple structure and labor saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

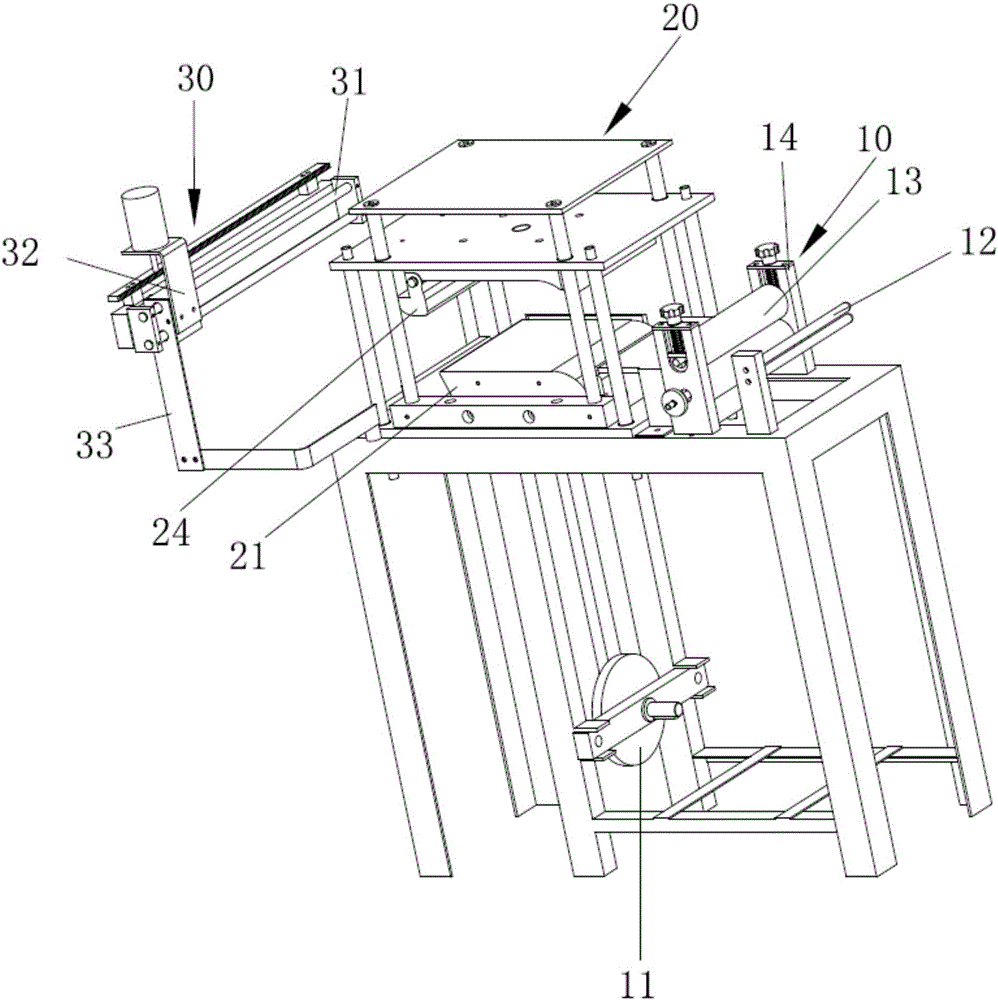

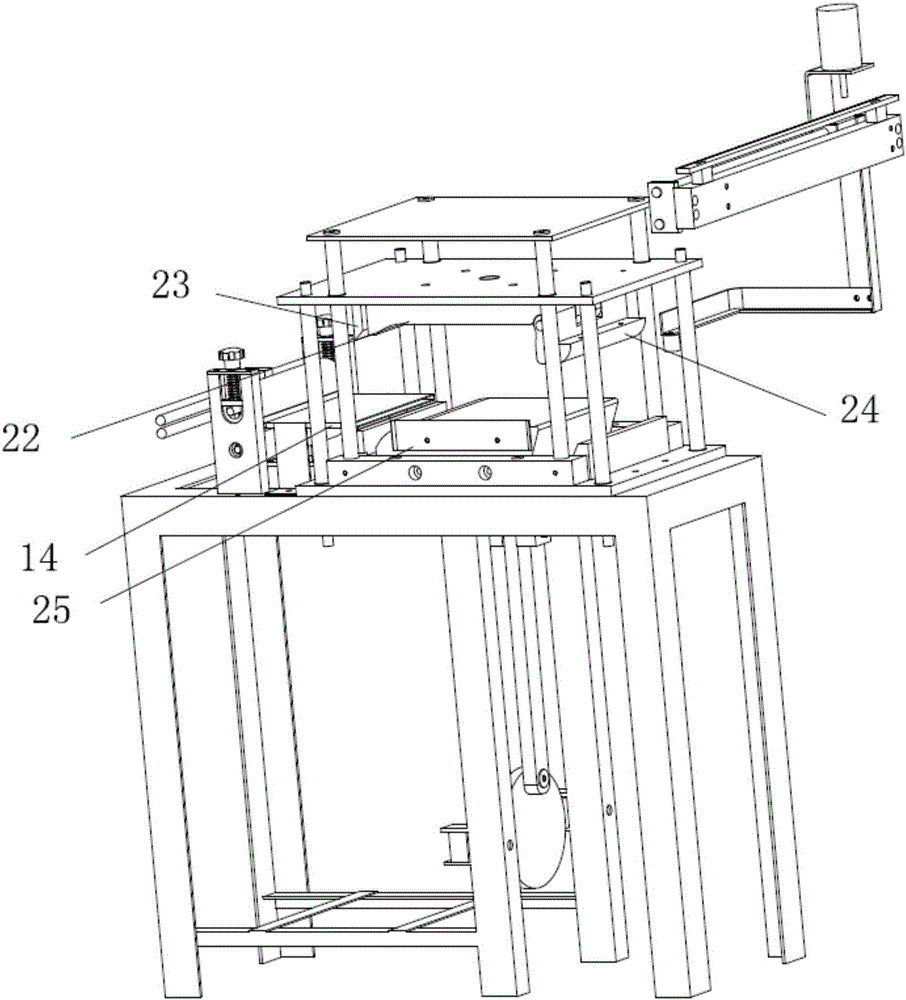

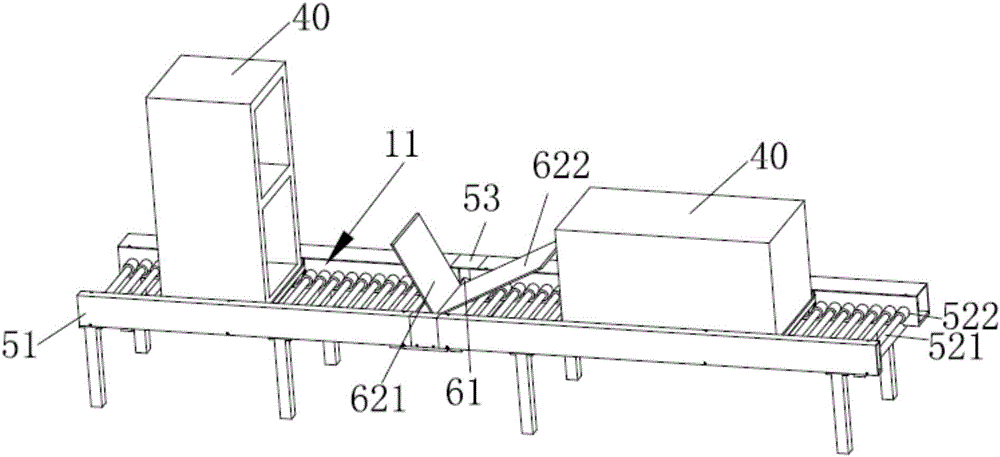

[0023] like Figure 1 to Figure 3 As shown, the anti-dropping structure of the wall brick vertical surface of the automatic paste printing machine of the present invention includes a steel wire mesh supply assembly 10 , a mortar hanging net forming assembly 20 and a mortar hanging net grabbing assembly 30 . The steel mesh supply assembly 10 includes a steel wire coil installation disc 11, which is fixed on the bottom of the support, and the steel wire net is coiled and placed on the steel wire coil installation disc 11, and the steel wire coil installation disc 11 rotates to extract the steel wire mesh. When the steel wire coil is placed, only need to be inserted into the installation shaft on the steel wire coil installation disc 11, it is easy to change. On the upper part of the bracket, two vertically juxtaposed steel wire mesh su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com