Sealing door of basement

A technology for sealing doors and basements, which is applied in windows/doors, door/window applications, building components, etc., and can solve problems such as unreasonable use of materials and waste of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

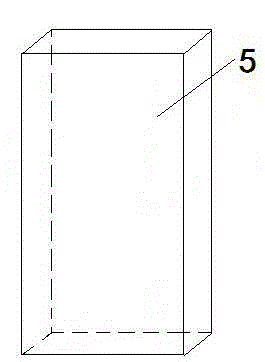

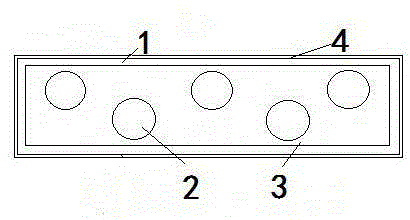

[0043] A basement airtight door, the airtight door includes a concrete airtight door blank and a titanium alloy plate wrapped outside the concrete airtight door blank, the concrete door blank includes a circular steel pipe and concrete wrapped around the circular steel pipe, the outer surface of the titanium alloy plate is coated Corrosion-resistant coating,

[0044] The element composition of titanium alloy plate is: Ni 5%, Si 2%, V 0.6%, Co 0.1%, Cr 0.08%, Nb 0.06%, Mn 0.04%, Ce 0.02%, the balance is titanium and unavoidable non-metallic inclusions According to the composition of the above elements, it is melted and poured into a slab, and the slab is hot-rolled at a temperature of 900°C, with a deformation of 15% per pass and a total deformation of 60%. After hot-rolling, it is air-cooled to room temperature, and the surface Then the plate is cold-rolled to reduce the thickness of the plate by 6%, and then the plate is stress-relieved annealed at 700°C, kept for 3 hours, ai...

Embodiment 2

[0056] A basement airtight door, the airtight door includes a concrete airtight door blank and a titanium alloy plate wrapped outside the concrete airtight door blank, the concrete door blank includes a circular steel pipe and concrete wrapped around the circular steel pipe, the outer surface of the titanium alloy plate is coated Corrosion-resistant coating,

[0057]The element composition of titanium alloy plate is: Ni 6%, Si 3%, V 0.7%, Co 0.2%, Cr 0.09%, Nb 0.07%, Mn 0.05%, Ce 0.03%, the balance is titanium and unavoidable non-metallic inclusions According to the composition of the above elements, it is melted and poured into a slab, and the slab is hot-rolled at a temperature of 900°C, with a deformation of 15% per pass and a total deformation of 60%. After hot-rolling, it is air-cooled to room temperature, and the surface Then the plate is cold-rolled to reduce the thickness of the plate by 6%, and then the plate is stress-relieved annealed at 700°C, kept for 3 hours, air...

Embodiment 3

[0069] A basement airtight door, the airtight door includes a concrete airtight door blank and a titanium alloy plate wrapped outside the concrete airtight door blank, the concrete door blank includes a circular steel pipe and concrete wrapped around the circular steel pipe, the outer surface of the titanium alloy plate is coated Corrosion-resistant coating,

[0070] The element composition of titanium alloy plate is: Ni 5.5%, Si 2.5%, V 0.65%, Co 0.15%, Cr 0.085%, Nb 0.065%, Mn 0.045%, Ce 0.025%, the balance is titanium and unavoidable non-metallic inclusions According to the composition of the above elements, it is melted and poured into a slab, and the slab is hot-rolled at a temperature of 900°C, with a deformation of 15% per pass and a total deformation of 60%. After hot-rolling, it is air-cooled to room temperature, and the surface Then the plate is cold-rolled to reduce the thickness of the plate by 6%, and then the plate is stress-relieved annealed at 700°C, kept for 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com