A monitoring method of flow control valve based on dcs data

A flow control valve and data technology, applied in valve devices, mechanical equipment, engine components, etc., can solve problems such as process difficulties and high costs, and achieve the goal of ensuring monitoring effects, reducing monitoring costs, and increasing human-computer interaction and learning capabilities. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

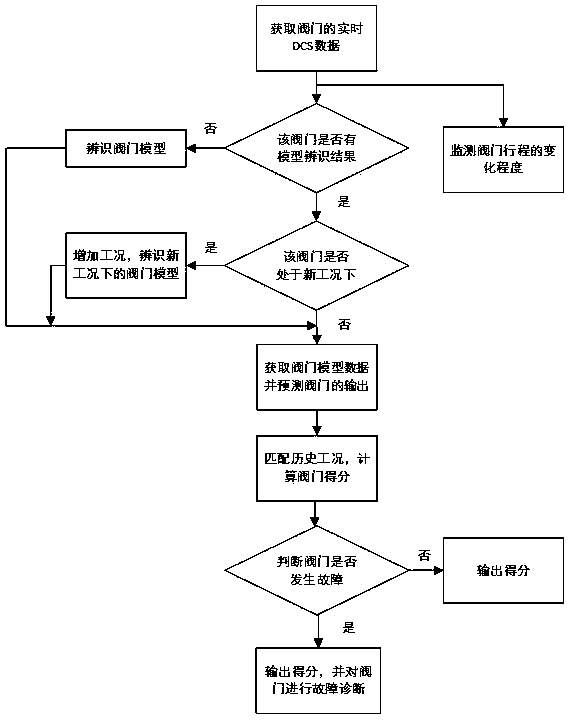

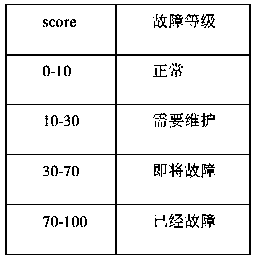

[0036] Such as figure 1 As shown, the flow control valve monitoring method based on DCS data of the present invention includes the following steps,

[0037] Step 1: Obtain valve DCS data as training data, classify the training data according to different working conditions, and establish various valve models.

[0038] The training data are the measurements of the valve controller ,output value , represents the valve opening, The representative is the flow value of the valve, and the above data are all obtained from the DCS database.

[0039] The valve model can be obtained according to the flow characteristics of the valve, for example: the relationship of the logarithmic valve is

[0040] ,

[0041] The linear valve relationship is , you can also set more complex hierarchical relationships, such as .

[0042] Step 2: Based on the training data, determine the corresponding valve models under different working conditions.

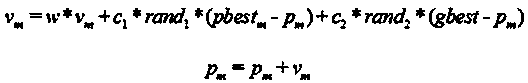

[0043] The parameters of each valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com