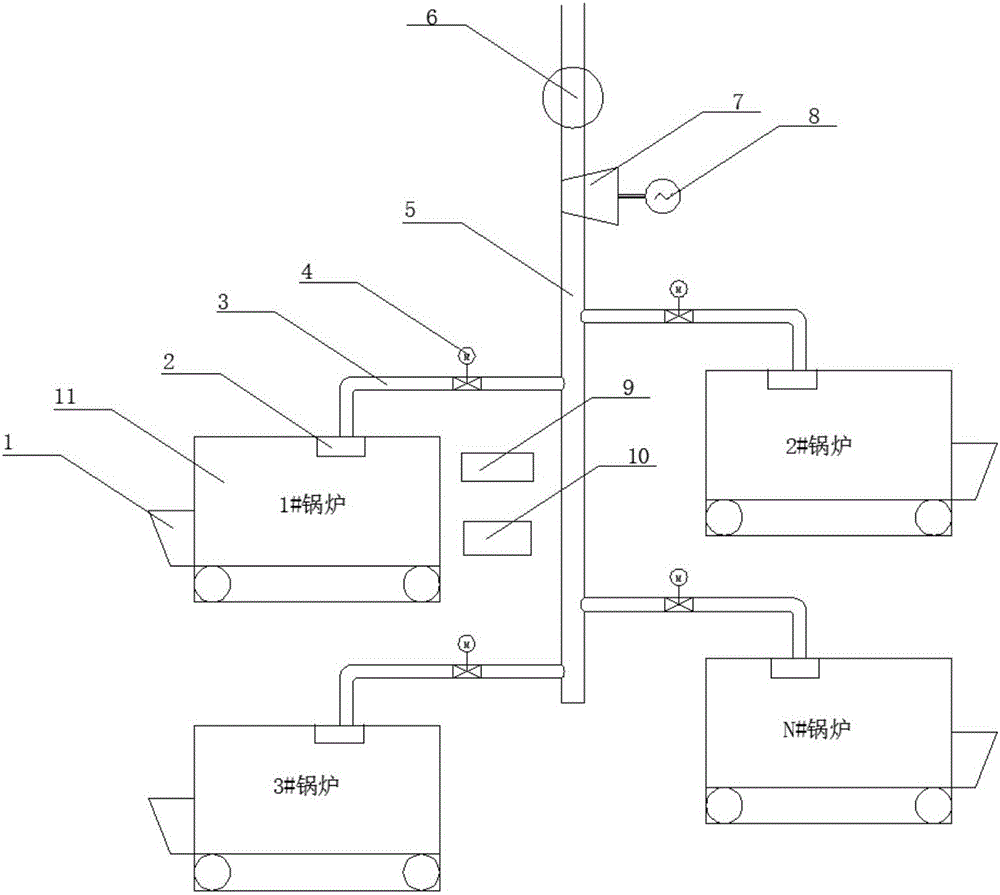

Boiler system with multiple boilers arranged in stacked mode

A multi-boiler and boiler technology, which is applied in the direction of steam generating devices, steam generating, lighting and heating equipment, etc., can solve the problems of poor load regulation ability and high concentration of dust and other pollutants, achieve low emission concentration and save flue gas treatment costs , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following is a detailed description of the embodiments of the present invention. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

[0018] A multi-boiler cascaded boiler system, a cascaded multi-boiler system, including multiple boiler bodies 1 with the same model and specification, boiler auxiliary equipment 9, control system 10, steam pipeline electric closing and opening valve 4, and steam main pipe 5 etc. Multiple boilers are 1# boiler, 2# boiler, 3# boiler...N# boiler. The number of boilers and boiler parameters depend on the power generation power of the designed power plant, and can be flexibly designed according to the demand. Each boiler has an independent Steam superheater 2, boiler auxiliary system 9 and control system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com