Sheet metal hot stamping force measurement device

A force measuring device and hot stamping technology, applied in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve problems such as the inability to accurately test the stamping force in real time, affecting the forming accuracy of sheet metal, and poor rigidity of the machine tool system. Achieve the effect of realizing online monitoring and fault identification, improving product quality and expanding the measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

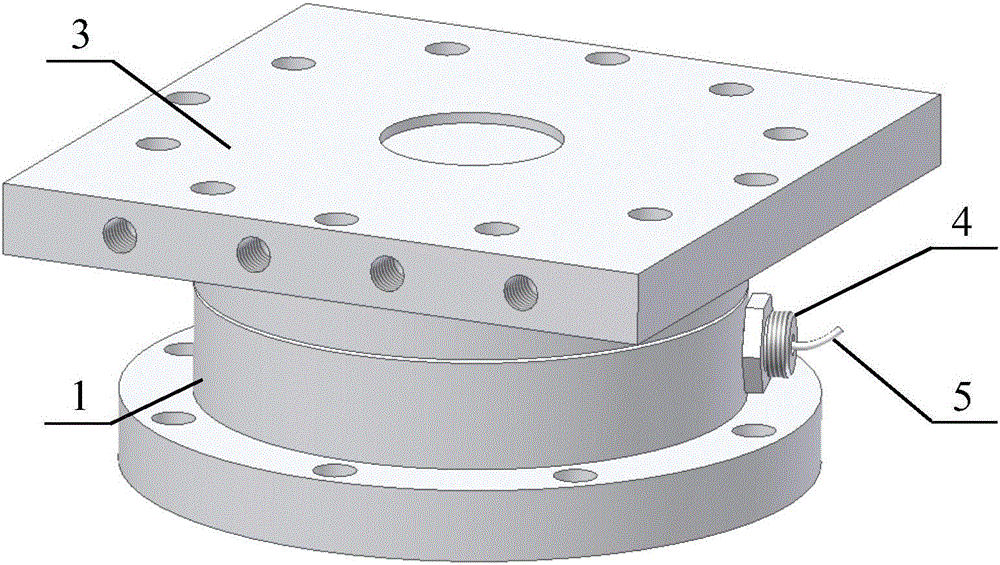

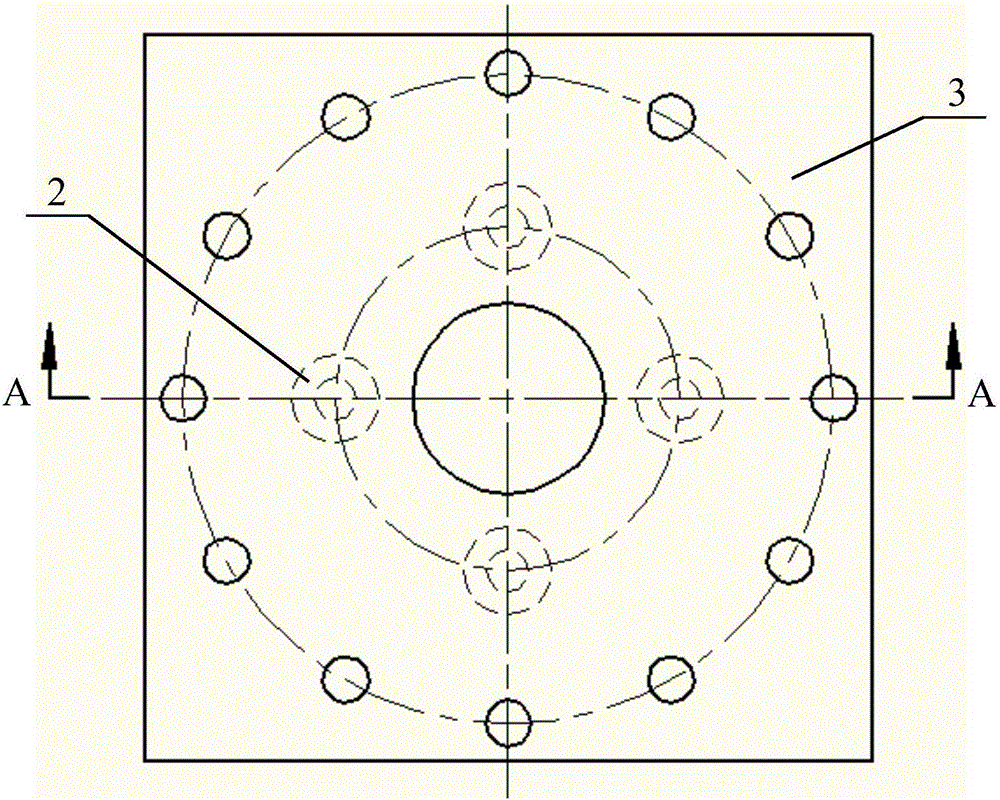

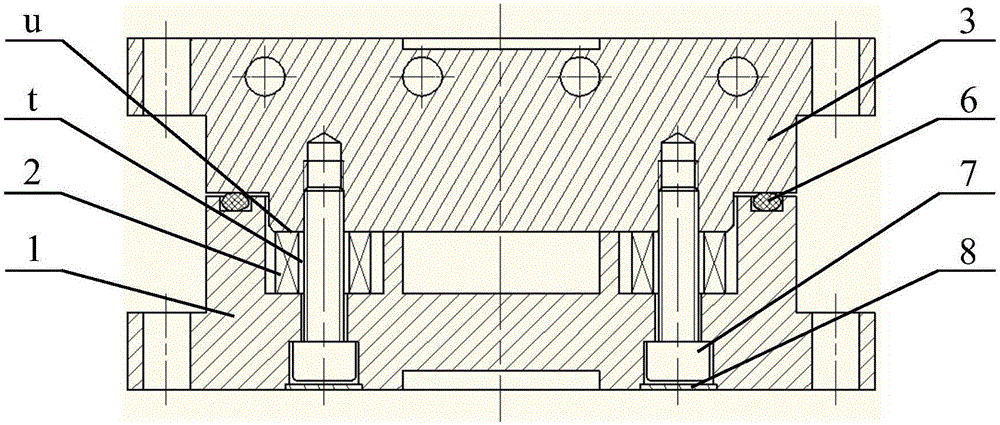

[0019] The specific implementation manner of the present invention will be described in detail in conjunction with the accompanying drawings and technical solutions. as attached figure 1 , 2 , 3, 4, 5, 6, 7, and 8, the four piezoelectric quartz sensors 2 are bonded to the bottom surface e of the annular hole b to ensure that the central holes t of the four piezoelectric quartz sensors are connected to the four The pre-tightening bolts are installed on the same axis as the stepped hole q, and the upper surface d of the load sharing ring at the center of the base 1 is strictly in the same plane as the upper surface u of the four piezoelectric sensors by grinding. The outgoing signals of the crystal group are connected in parallel, and are drawn out of the body through the lead wire 5 through the lead wire output connector 4 . Four pre-tightening bolts 7 are used to rigidly connect the base 1, the four piezoelectric quartz sensors 2 and the upper cover 3 through four stepped ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com