A Method for Obtaining Droplet Contact Angle on Regular Second-Order Structured Surface

A technology of structured surface and acquisition method, applied in instrumentation, design optimization/simulation, calculation, etc., can solve the problems of large result error and complicated process of measuring contact angle of solid surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

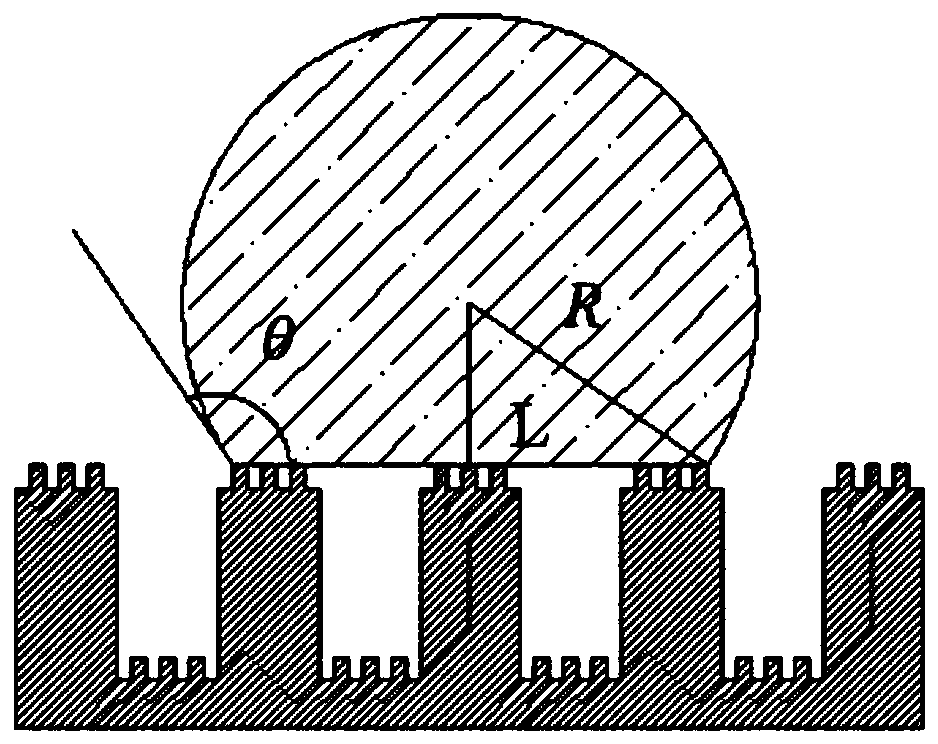

[0157] (1) In order to ignore the influence of gravity on the contact angle of the droplet on the solid surface, the volume of the droplet is taken as V=5μl, and the intrinsic contact angle of the material forming the second-order structure, that is, Young’s contact angle, is taken as θ Y =105° (different materials correspond to different intrinsic contact angles).

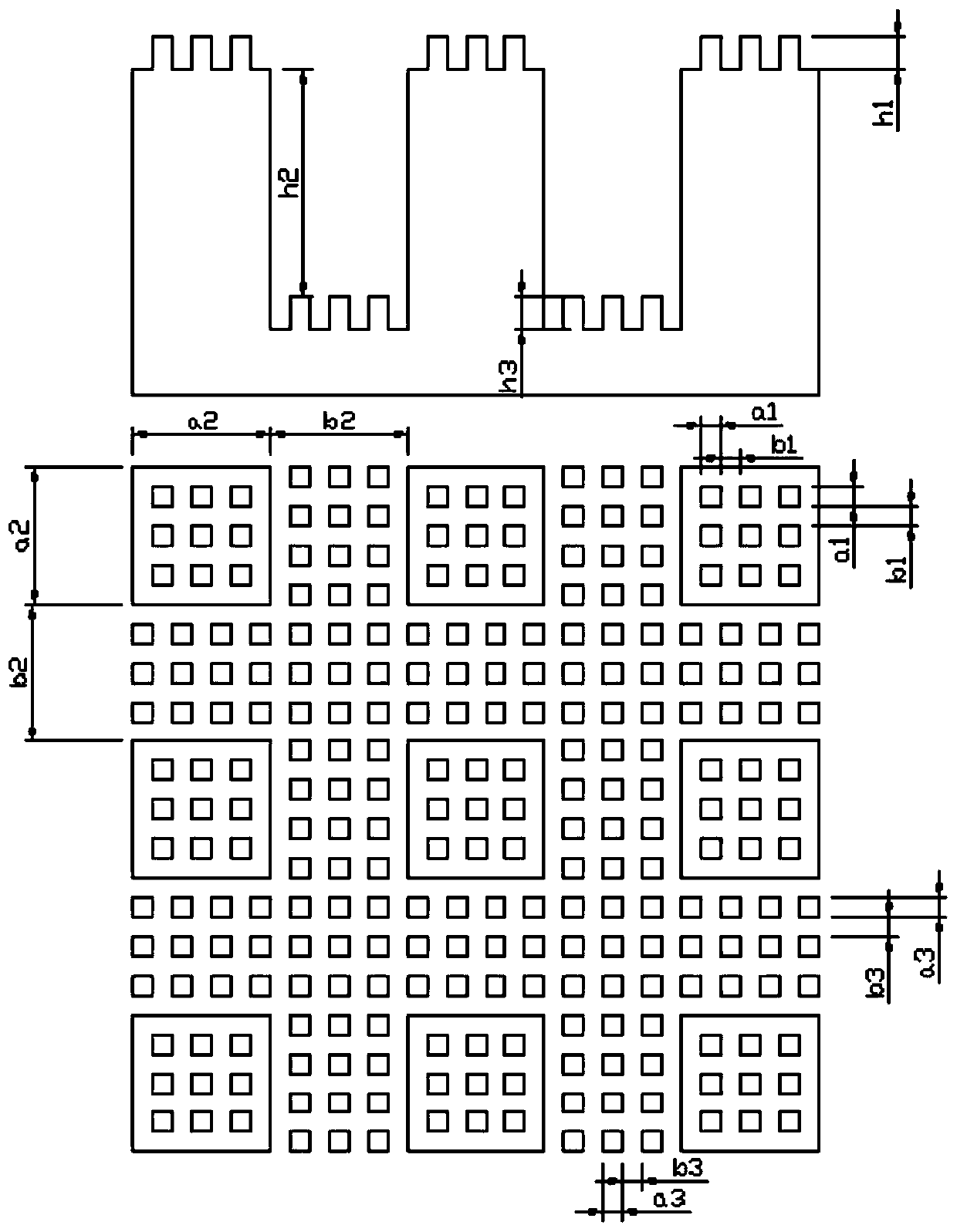

[0158] The geometric structure size parameters of the second-order structure are: the side length, spacing, and height of the top nanopillars are respectively a 1 =100nm,b 1 =90nm, h 1 = 200nm, the side length, pitch and height of the microcolumn are respectively a 2 =10μm,b 2 =9μm,h 2 =20μm, the side length, spacing and height of the bottom nanopillars are respectively a 3 =100nm,b 3 =90nm, h 3 = 200nm.

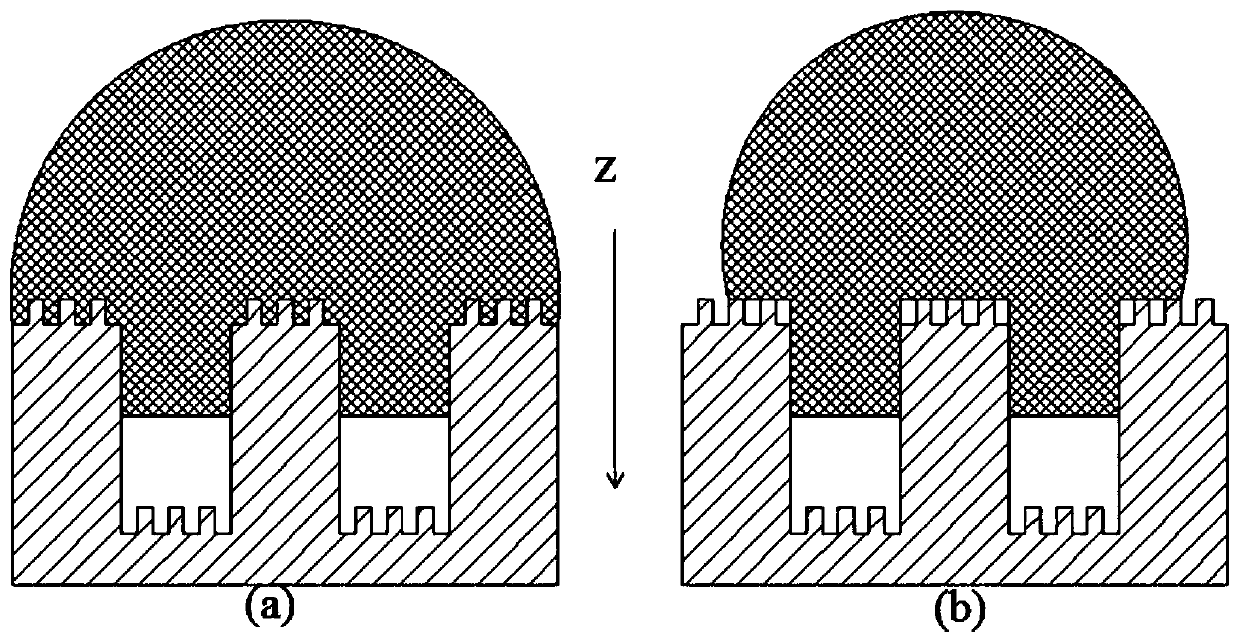

[0159] (2) For two different droplet infiltration modes in the second-order structure, the increment of the infiltration depth z is five percent of the length of each infiltration interval; for formula (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com