Dielectric waveguide filter

A dielectric waveguide and filter technology, applied in the field of dielectric waveguide filters, can solve the problems of high process requirements, high cost, complex coupling structure, etc., and achieve the effect of low process requirements, low cost, and simple coupling structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

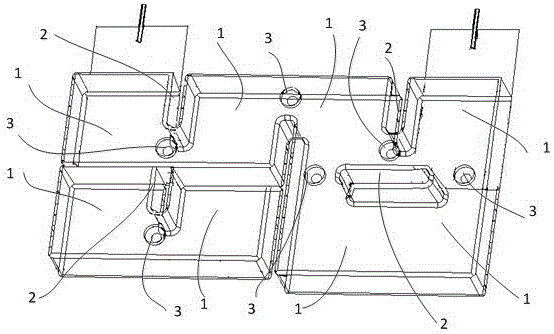

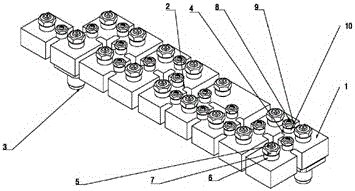

[0019] Such as figure 2 As shown, it is a dielectric waveguide filter provided in the embodiment of the present invention. The dielectric waveguide filter includes a plurality of interconnected resonators 1, and coupling windows 2 and coupling holes are formed between adjacent resonators 1. 3; among them,

[0020] Each coupling window 2 is a hollow cavity structure, and the inner wall of each coupling window 2 is coated with a first metallized coating for electromagnetic shielding;

[0021] Each coupling hole 3 is a blind hole arranged close to the corresponding coupling window 2, and the inner wall of each coupling hole 3 is coated with a second metallized coating for electromagnetic shielding;

[0022] The coupling amount of the dielectric waveguide filter ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com