Regeneration electromotive force discharge device for DC drive

A discharge device and DC drive technology, applied in the direction of emergency protection circuit device, circuit device, emergency protection circuit device, etc. for limiting overcurrent/overvoltage, can solve the problem of overvoltage protection of switching power supply, system malfunction, Problems such as power-off and restart of the chip can achieve the effects of low on-resistance, saving assembly space, and reducing hardware costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

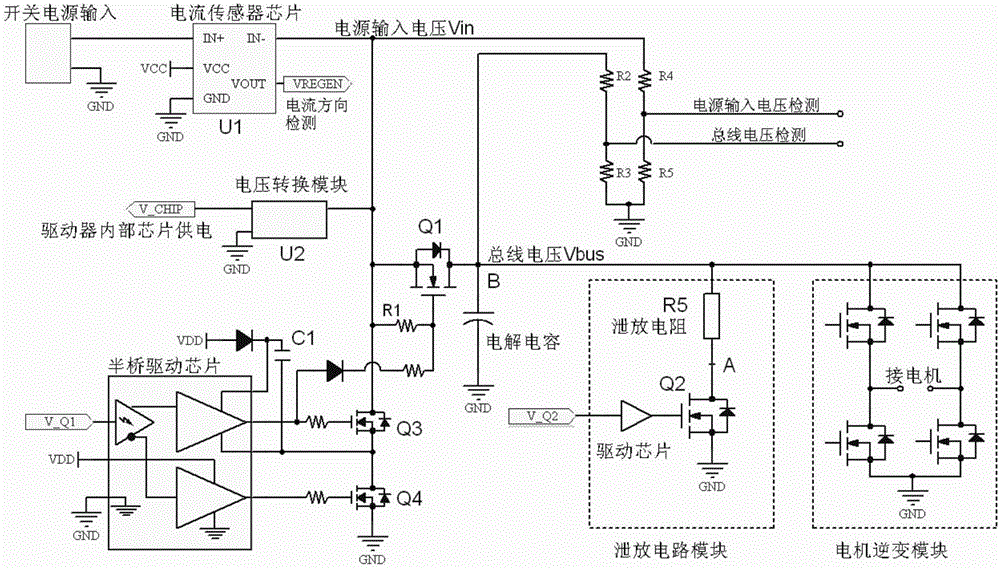

[0038] Such as figure 1 As shown, the present invention can be used for the regenerative electromotive force discharge device of the DC drive. By adding a simple discharge circuit inside the DC drive and then matching it with DSP control, the effective discharge of the regenerative electromotive force of the DC drive can be realized, and the normal operation of the power supply can be ensured. Work.

[0039] The hardware principle is explained here:

[0040] Through the current sensor chip monitoring the current flow in and out on the bus, the DSP compares its output voltage with the reference voltage to obtain the current flow state, thereby controlling the on and off of the MOS tube on the bus to cut off the regenerative electromotive force return to the switching power supply. After the internal bus voltage of the driver is raised, the MOS tube of the discharge circuit is turned on, and the regenerative electric energy is discharged. The whole process will not affect the...

Embodiment approach

[0048] The DC drive regenerative electromotive force discharge method mentioned in the present invention is divided into 2 actions: controlling the MOS tube Q1 on the bus and controlling the discharge circuit MOS tube Q2, such as figure 1 shown.

[0049] 1. In the case of no need to discharge normally, the bus MOS tube Q1 is turned on, and the MOS tube Q2 of the bleeder circuit is turned off;

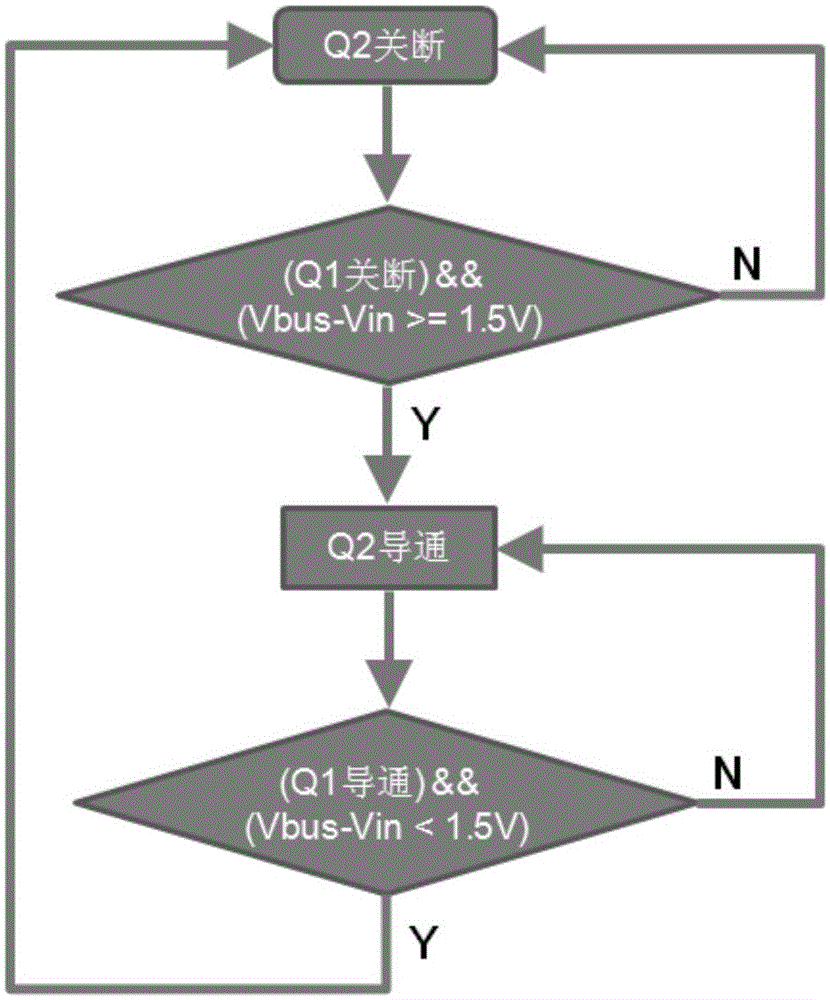

[0050] 2. The operation after the regenerative electromotive force is detected is: first turn off the bus MOS transistor Q1, and then turn on the discharge circuit MOS transistor Q2 to discharge the energy.

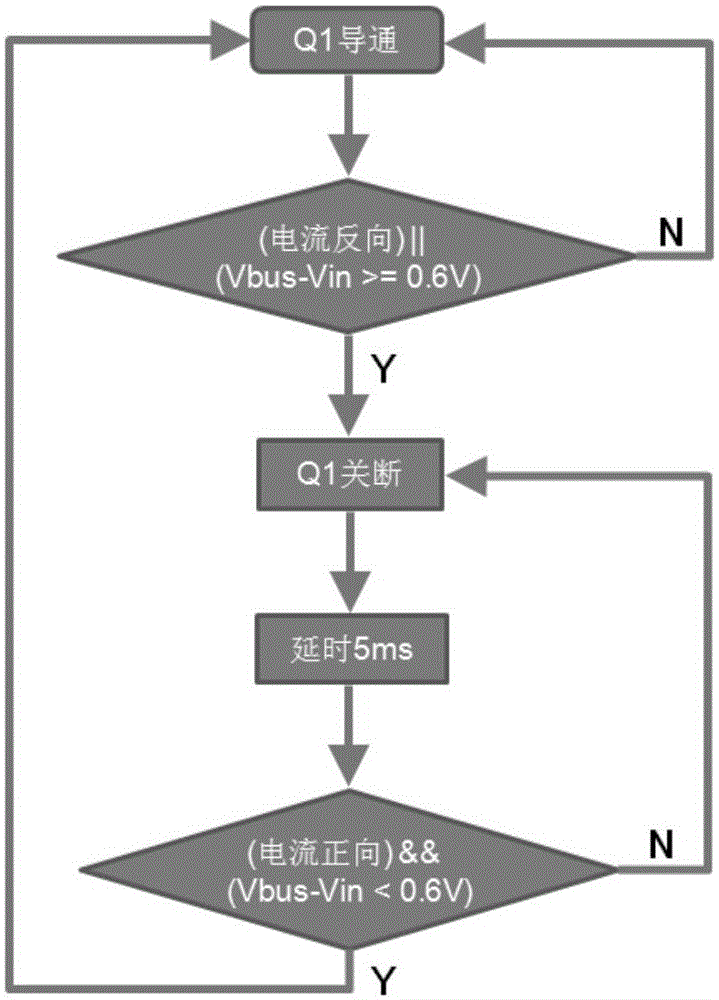

[0051] The turn-off conditions of the bus MOS tube are two:

[0052] (1) There is a reverse current;

[0053] (2), the bus voltage is higher than the power input voltage by a certain difference (for example, the difference is set to 0.6V);

[0054]As long as one of the conditions (1) and (2) is met, the bus MOS transistor Q1 is set to be turned off. In order to avoid the high-f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com