Method and apparatus for infiltration of a micro/nanofiber film

A technology of fiber membrane and impregnation, which is applied in the direction of hot-dip plating process, coating, metal material coating process, etc., can solve the problems of not being able to achieve sufficient pressure, undesired, etc., and achieve the effect of favorable composite material properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention will now be described more fully hereinafter with reference to the accompanying drawings, in which presently preferred embodiments of the invention are shown. However, this invention may be embodied in many different forms and should not be construed as limited to the embodiments set forth herein; rather, these embodiments are provided for sufficiency and completeness, and to teach one skilled in the art person fully conveyed the scope of the invention. The same reference numerals refer to the same elements throughout.

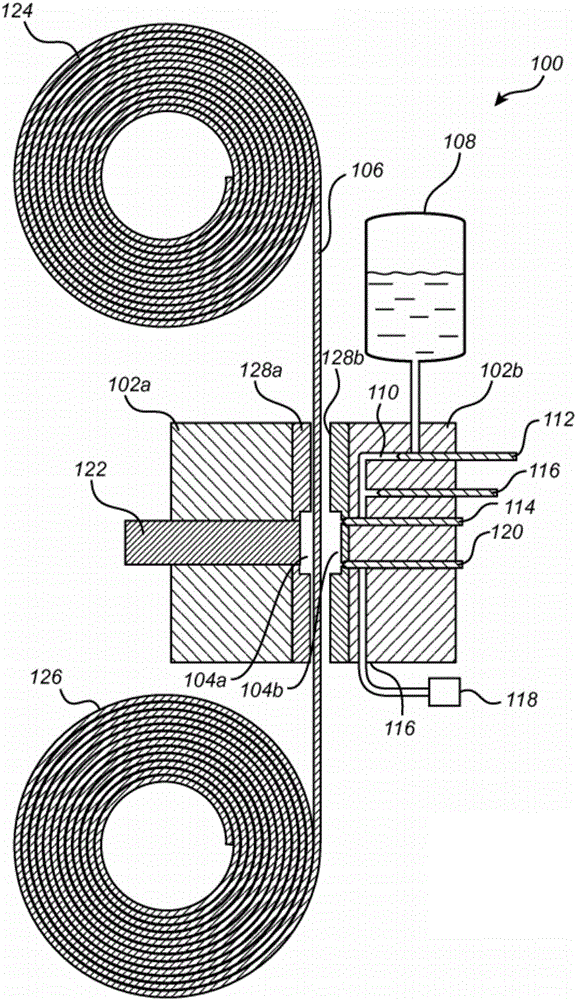

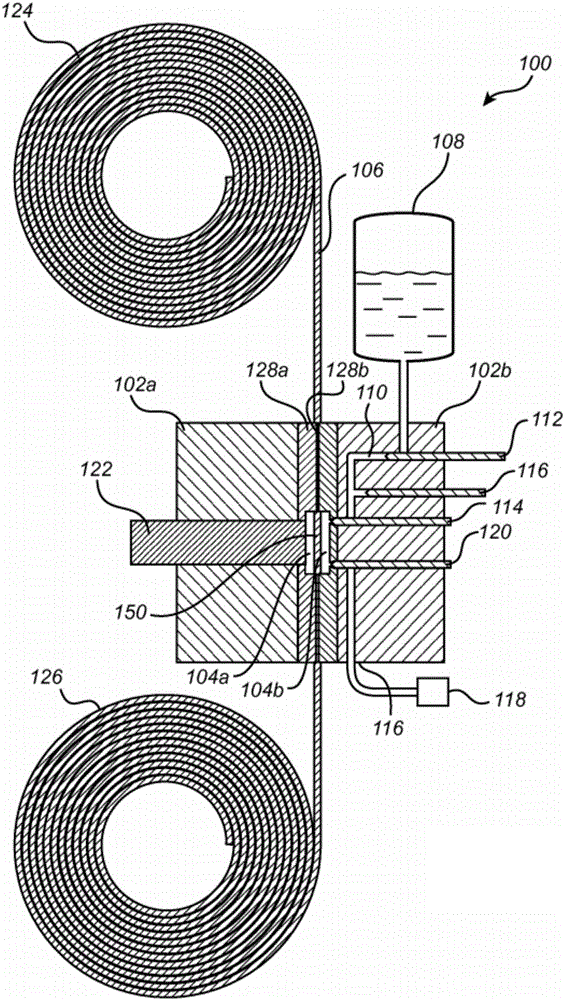

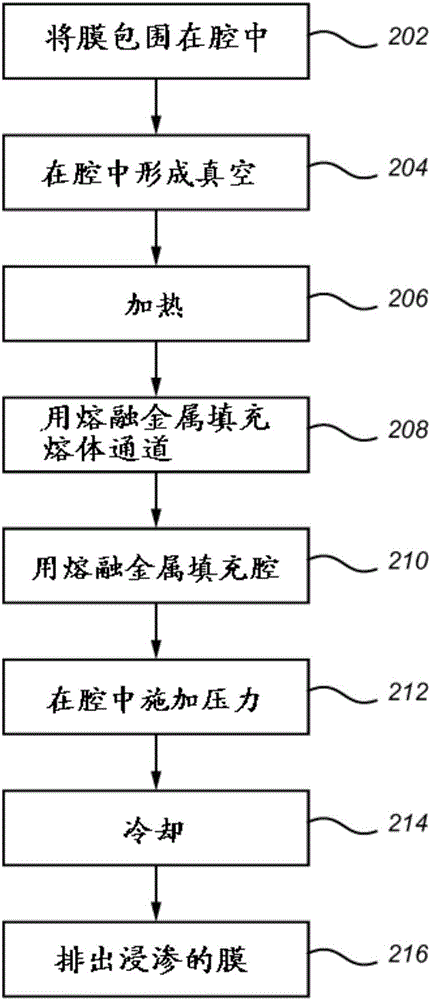

[0029] The present invention relates to a process for the complete and uniform infiltration of a metal / alloy matrix material into a continuous film of micro- and / or nanofibers. More specifically, the present invention relates to processes and tools for forming such composite materials in roll-to-roll production.

[0030]Figure 1 schematically illustrates an apparatus 100 for roll-to-roll manufacture of impregnated micro / nanofibrous membr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com