Heat-dissipating structure

A heat sink and heat sink technology, applied in the direction of heat transfer modification, arrangement of circuit elements without support structure, heat exchange equipment, etc., can solve the problems of increasing resistance, increasing power loss, etc., and achieve lower resistance and high heat dissipation sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

[0039] In the following description, in order to facilitate the identification of each constituent element, there may be situations in which different scaling factors are marked in the drawings according to different constituent elements.

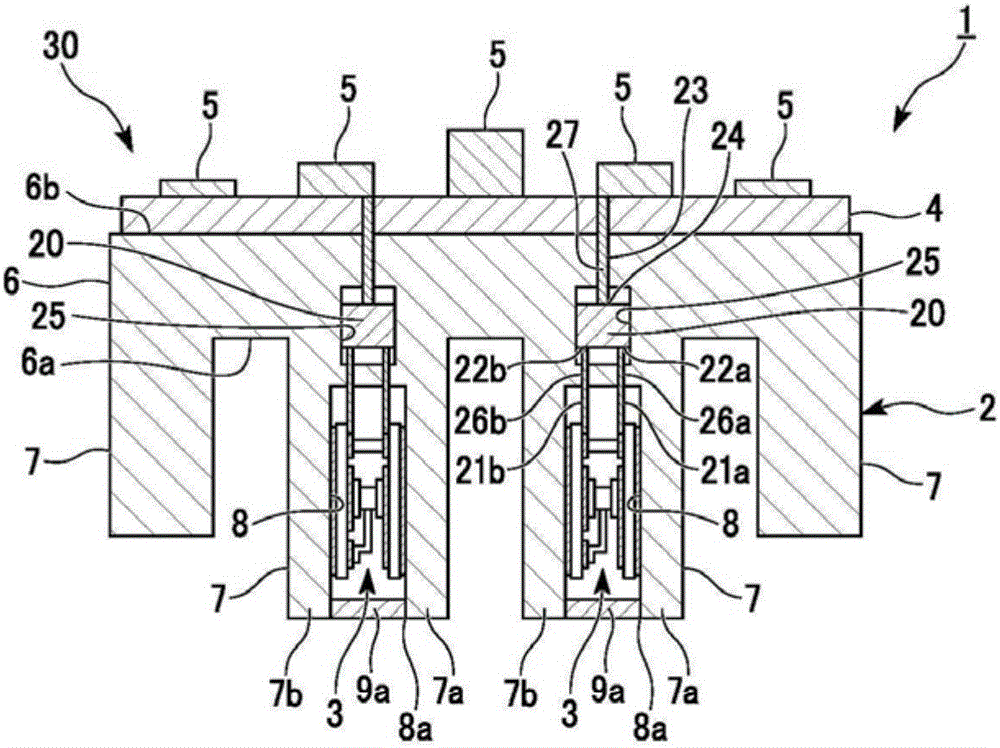

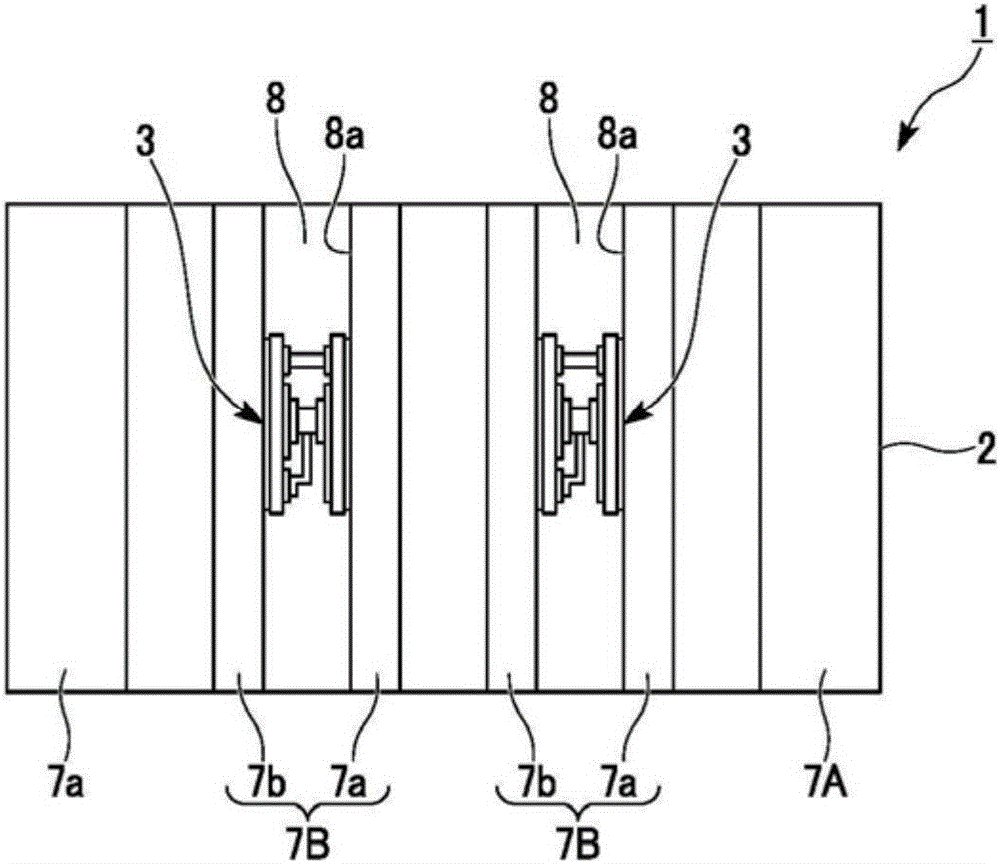

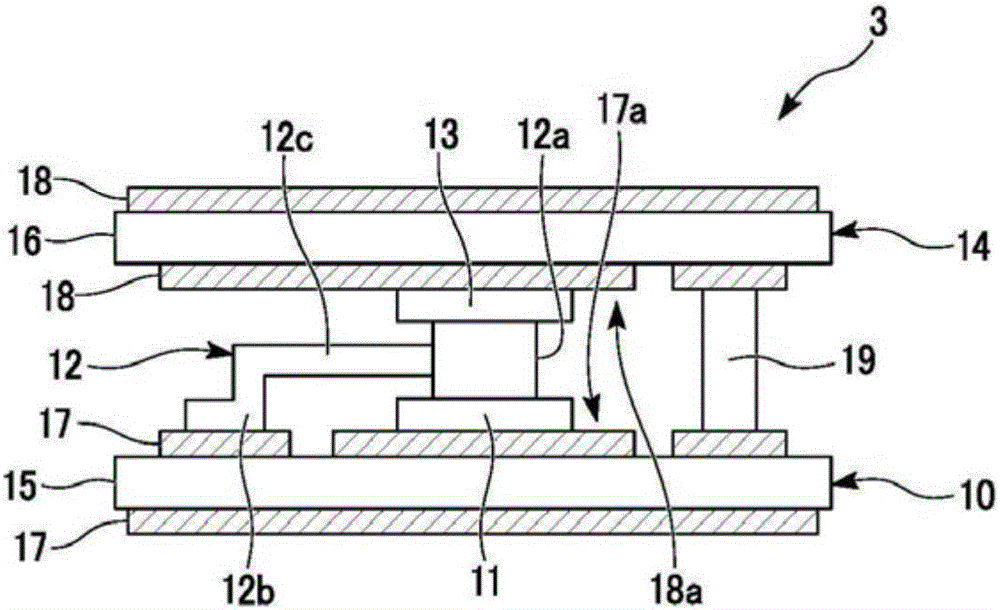

[0040] refer to figure 1 as well as figure 2 The heat radiation structure 1 which is one embodiment of this invention is demonstrated.

[0041] Heat dissipation structure 1 such as figure 1 as well as figure 2 As shown, in a semiconductor device including a heat sink 2, a plurality of semiconductor modules (first heat generating components) 3, a circuit substrate 4, and a plurality of electronic components (second heat generating components) 5, the semiconductor A structure in which the heat emitted by the module 3 and the electronic component 5 is dissipated.

[0042] Specifically, in the heat dissipati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com