Semi-automatic garlic planter

A planting machine and semi-automatic technology, applied in the field of agricultural machinery, can solve the problems of inability to realize upright planting with cusps upward, irregular shape of garlic seeds, failure to meet the requirements of garlic planting, etc., and achieve simple structure, good adaptability and practicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

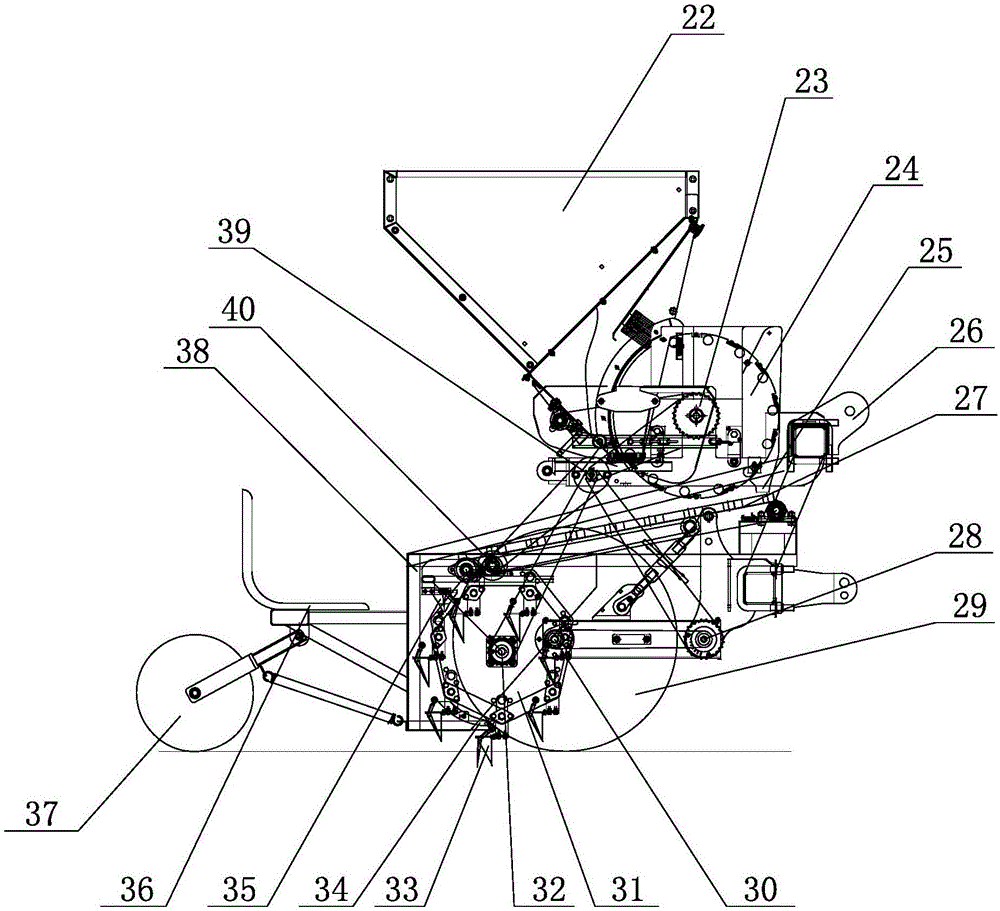

[0025] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

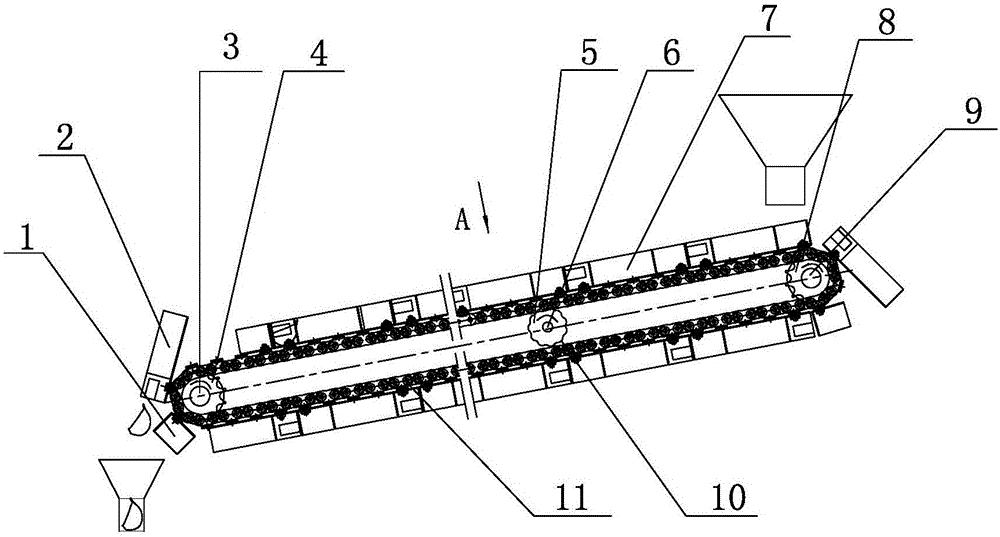

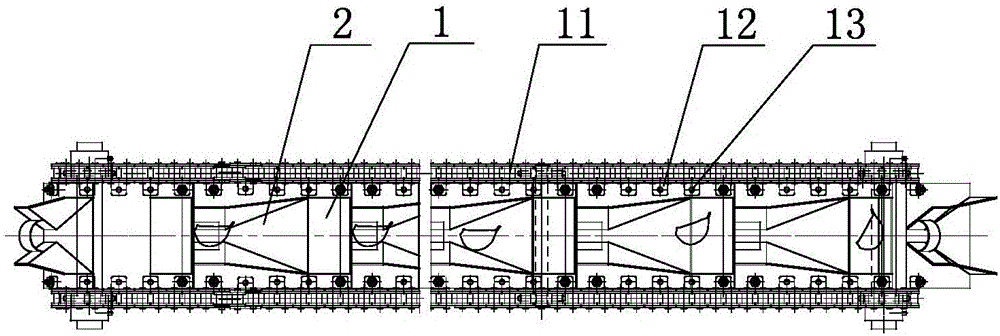

[0026] Such as figure 1 As shown, the semi-automatic garlic planter of the present invention includes a fixed bracket 38, the top of the fixed bracket 38 fixes the seed box 22 and the seed meter 24, the outlet of the seed box 22 corresponds to the entrance of the seed meter 24, and the seed meter 24 The seed discharge port 25 of 24 corresponds to the combined hopper 7 arranged at the front end of the orientation device 27 below the seed meter 24, and the end of the corresponding orientation device 27 is provided with a hopper II 35 below it, and a vertical seeding turntable 31 is fixed below the hopper II 35 The outlet of the receiving hopper II 35 corresponds to the duckbill 33 arranged on the vertical seed turntable 31. There are multiple duckbills 33 and are evenly distributed on the vertical seed turntable 31 along the circumference. The matching duckbill o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com