Double-layer film covering method for greenhouse

A greenhouse and double-layer film technology, applied in the field of greenhouses, can solve the problems of high cost, opacity, and high cost of quilts, and achieve the effects of low cost, humidity adjustment, and good heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

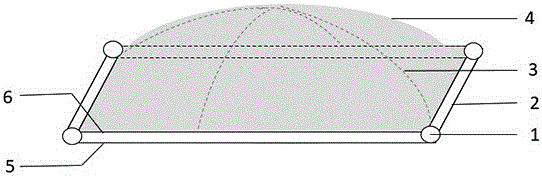

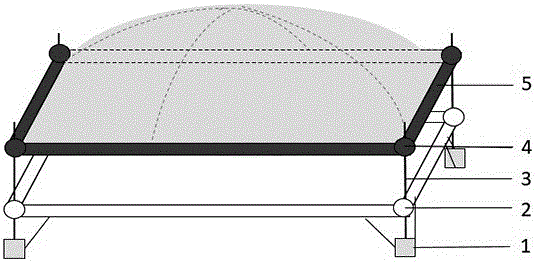

[0008] Such as figure 1 , when covering and fixing the double-layer film: cut two layers of plastic film according to the geometric plane surrounded by the support rod, paste the outer plastic film on the outer top surface of the support rod, insert a high-elastic elastic rod such as carbon fiber into the support rod, and use the elasticity of the elastic rod The outer film is arched to form an arc surface, and then the inner film is pasted on the inner bottom surface of the support rod. Such as figure 2 , when covering the movable double-layer membrane: according to the geometric plane surrounded by the support rods, find several intersection points of the support rods, insert a threaded shaft perpendicular to the two intersecting support rods at each intersection point and penetrate through it, and connect the step below the threaded shaft The rotating shaft of the stepping motor is fixed to the stepping motor and the support rod. Make a covering frame according to the ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com