Cooling device with waste gas absorbing equipment

A technology of absorption equipment and heat dissipation device, which is applied in the fields of dust removal, chemical/physical/physicochemical processes, chemical instruments and methods, etc. It can solve the problems of incomplete heat dissipation, single function, low utilization rate of heat dissipation devices, etc., and achieve the effect of heat dissipation Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

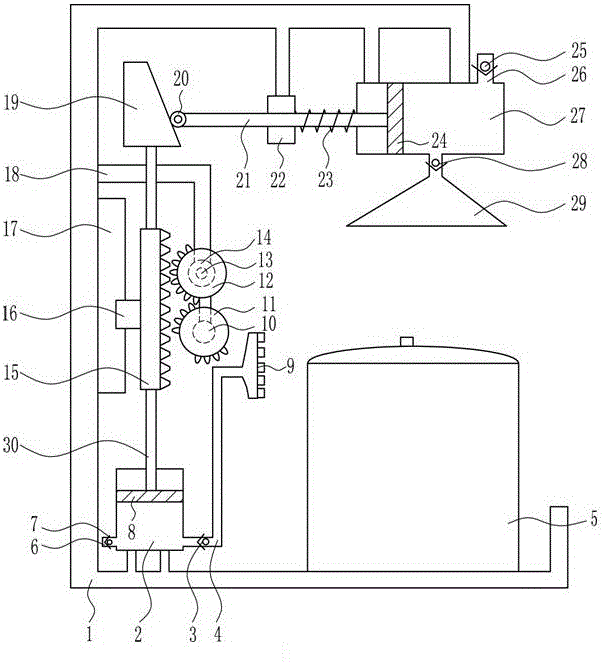

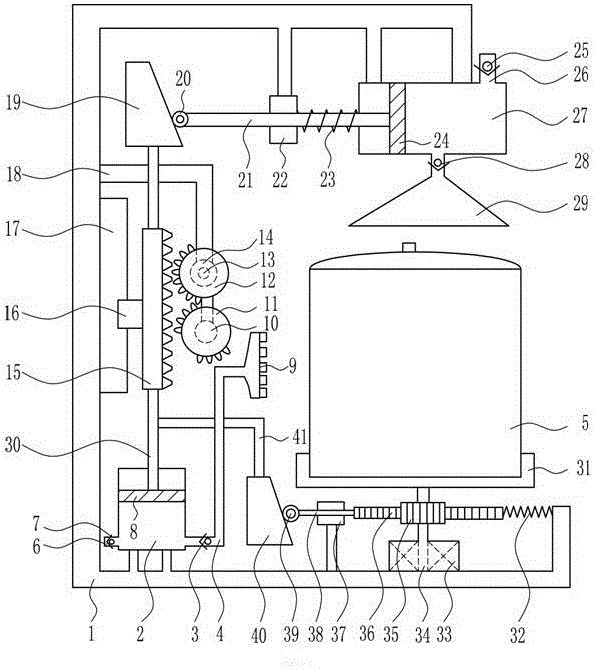

[0026] A cooling device with exhaust gas absorption equipment, such as Figure 1-2As shown, it includes a fixed frame 1, a first cylinder body 2, an outlet pipe 3, a first one-way valve 4, a reaction kettle 5, a water inlet pipe 6, a second one-way valve 7, a first piston 8, a nozzle 9, and a nozzle 9 , rotating motor 10, first incomplete gear 11, second incomplete gear 12, first rotating shaft 13, first bearing seat 14, first rack 15, slider 16, slide rail 17, first connecting rod 18, The first wedge block 19, the first contact roller 20, the first moving rod 21, the first guide rail 22, the first spring 23, the second piston 24, the third one-way valve 25, the air outlet pipe 26, the second cylinder body 27, The fourth one-way valve 28, the suction head 29 and the lifting rod 30, the bottom of the fixed frame 1 is connected with the first cylinder body 2 through bolt connection, and the left side of the bottom of the first cylinder body 2 is connected with the flange connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com