A kind of preparation method and application of zn/g-c3n4 ozone catalyst

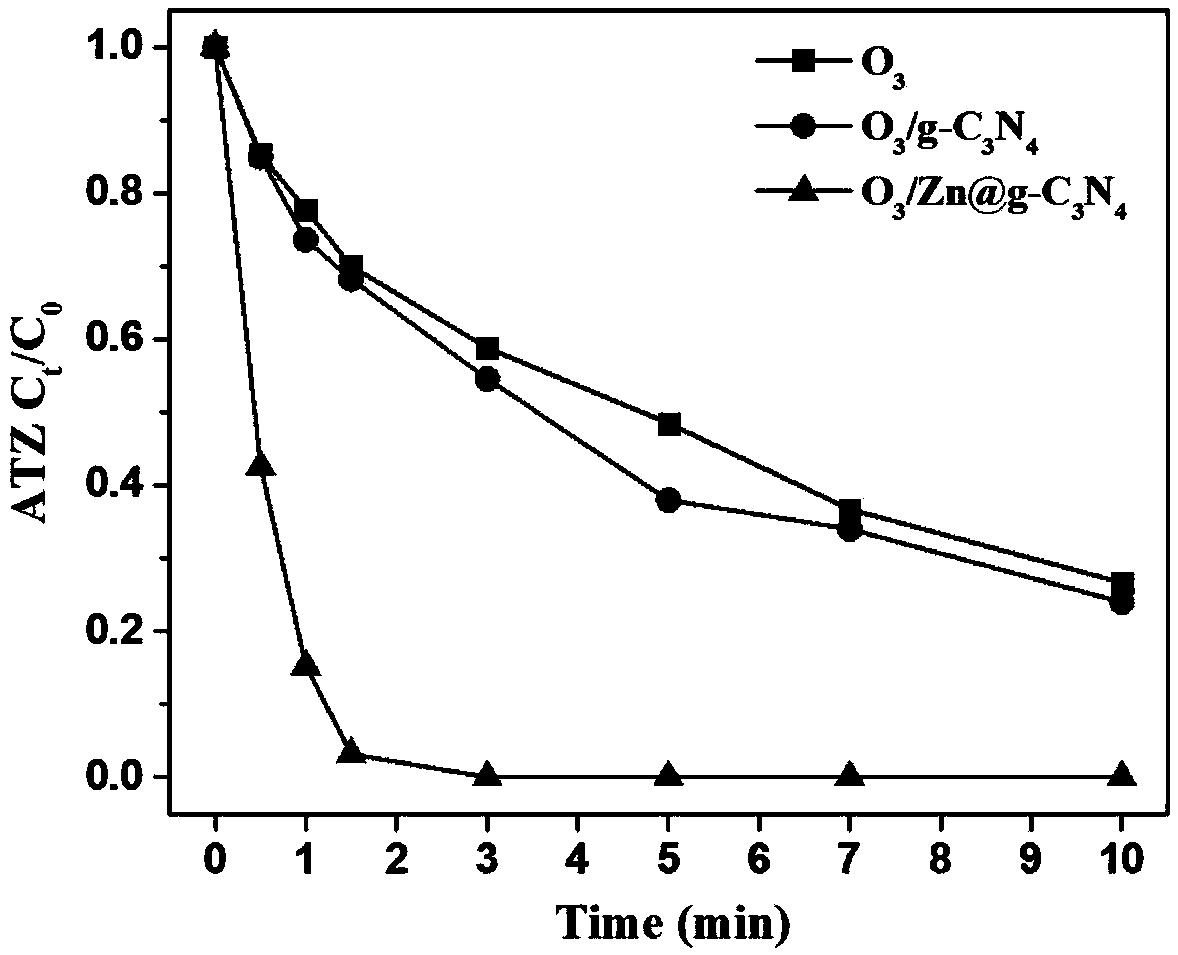

A technology of g-c3n4 and catalyst is applied in the field of water pollution control, which can solve the problems of catalyst activity reduction and environmental pollution, and achieve the effects of accelerated degradation and removal, broad application prospects and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

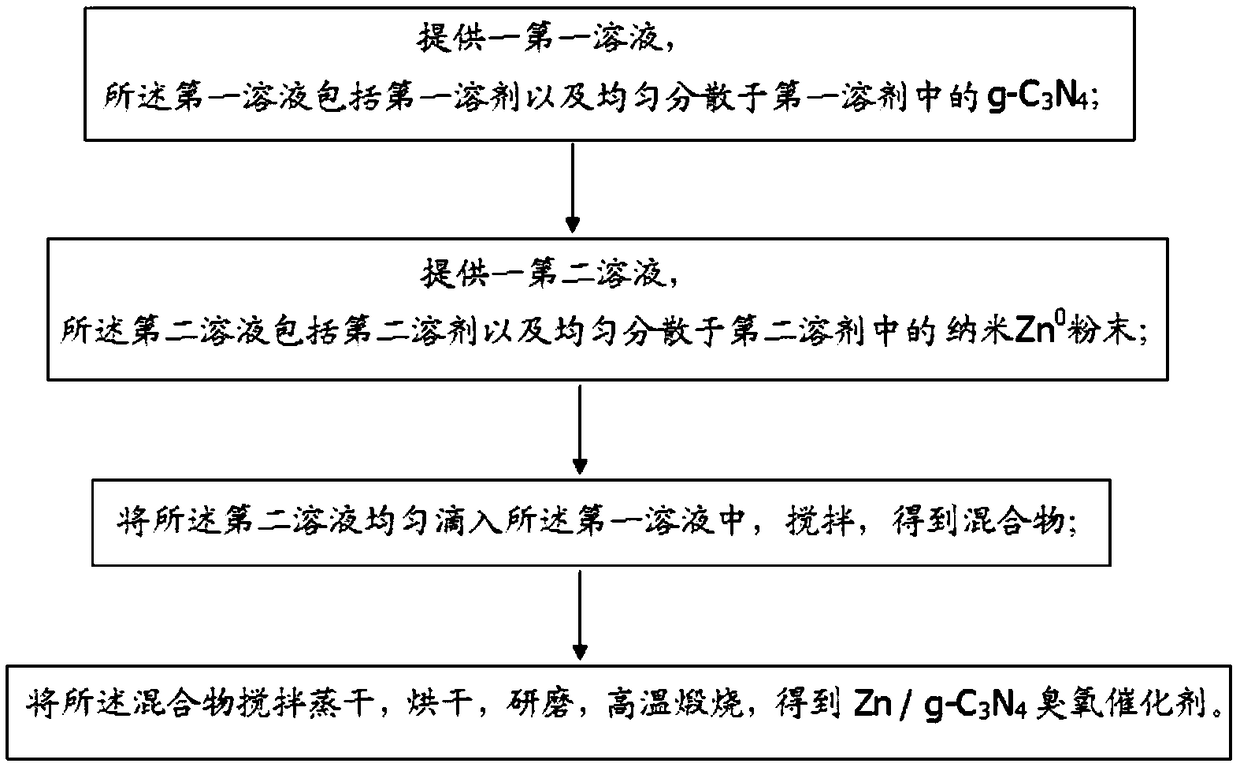

[0034] like figure 1 Shown, the embodiment of the present invention Zn / g-C 3 N 4 The preparation method of ozone catalyst, described method comprises the steps:

[0035] A first solution is provided, the first solution includes a first solvent and g-C uniformly dispersed in the first solvent 3 N 4 ;

[0036] A second solution is provided, the second solution includes a second solvent and nanometer Zn uniformly dispersed in the second solvent 0 powder;

[0037] uniformly drop the second solution into the first solution, and ultrasonically stir to obtain a mixture;

[0038] The mixture was stirred and evaporated to dryness, dried, ground, and calcined at high temperature to obtain Zn / g-C 3 N 4 Ozone catalyst.

[0039] Graphite carbon nitride (g-C 3 N 4) is an allotrope of carbon nitride, which has a unique graphite-like layered stacking structure and sp2 hybridized π-conjugated electronic band structure. Because it has a certain absorption for visible light, it also h...

Embodiment 1

[0046] g-C 3 N 4 preparation of

[0047] Weigh a certain amount of melamine into a crucible, put the crucible into a muffle furnace, and bake it at a heating rate of 5°C / min at 550°C for 2 hours. After the crucible is cooled, take it out to obtain light yellow powder g-C 3 N 4 , grind and set aside.

[0048] Zn / g-C 3 N 4 preparation of

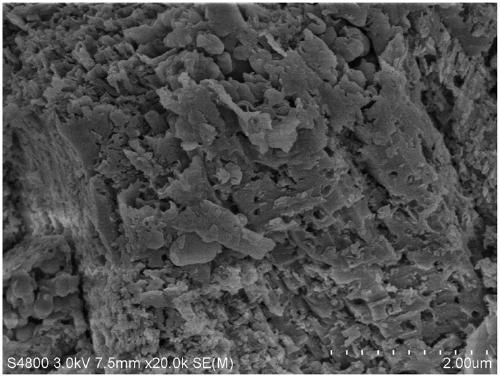

[0049] Weigh 6g g-C 3 N 4 The powder is evenly dispersed in 30mL ethanol; weigh 0.325g of nano-Zn 0 powder, evenly dispersed in 20mL ethanol water; the nano-Zn 0 Add the powder solution to g-C evenly drop by drop 3 N 4 solution, with vigorous stirring, after the dropwise addition, 30 ° C ultrasonic stirring for 30 min; then the mixture was placed in an 80 ° C water bath and stirred until dry, dried in a 70 ° C oven, after uniform grinding, placed in Crucible, then placed in a muffle furnace, heated to a different temperature of 350°C at a heating rate of 3°C / min, and calcined at a constant temperature at a target temperature of 350...

Embodiment 2

[0054] g-C 3 N 4 preparation of

[0055] Weigh a certain amount of melamine into a crucible, put the crucible into a muffle furnace, and bake it at 500°C for 3 hours at a heating rate of 5°C / min. After the crucible is cooled, take it out to obtain light yellow powder g-C 3 N 4 , grind and set aside.

[0056] Zn / g-C 3 N 4 preparation of

[0057] Weigh 6g g-C 3 N 4 The powder is evenly dispersed in 30mL of methanol; weigh 0.425g of nano-Zn 0 powder, evenly dispersed in 20mL methanol water; the nano-Zn 0 Add the powder solution to g-C evenly drop by drop 3 N 4 solution, with vigorous stirring, after the dropwise addition, 20 ° C ultrasonic stirring for 60 min; then the mixture was placed in a 70 ° C water bath and stirred until dry, placed in a 60 ° C oven for drying, after uniform grinding, placed in Crucible, then placed in a muffle furnace, heated to a different temperature of 300°C at a heating rate of 3°C / min, and calcined at a constant temperature at a target te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com