New processing technology of street lamp arm and auxiliary rail car for spraying and baking

A technology for railcars and new technology, which is applied in the direction of coating, spraying device, and device for coating liquid on the surface, etc. It can solve the problems of product quality to be improved, uneven paint spraying, inconvenient operation, etc., and achieve convenient spraying process , improve product quality, the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

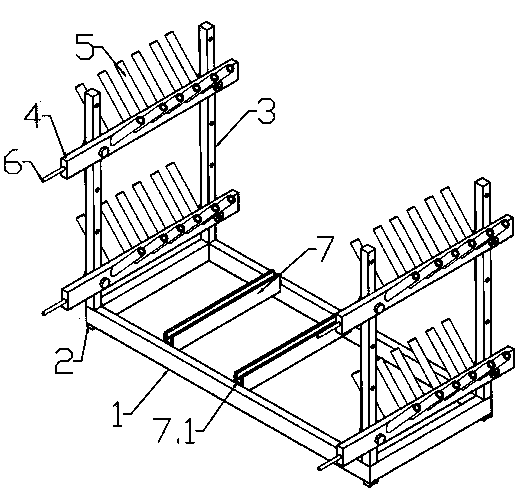

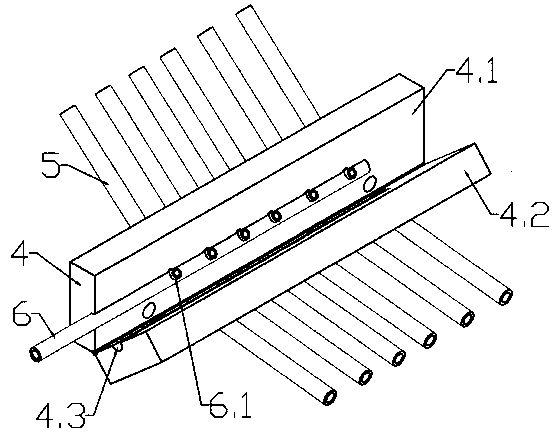

[0018] like figure 1 , figure 2 , image 3 As shown, the street lamp arm spraying and baking auxiliary rail car of the present invention includes a base 1, a slider 2 installed on the bottom of the base 1 and a plurality of sets of support rods 3 detachably installed on the top of the base 1. There are detachable (bolts, bolt holes) at different height positions between the rods 3 (two support rods 3) to fix the horizontal lamp arm support rod 4, which is detachably (threaded) connected to the lamp arm support rod 4. The lamp arm support 5, the angle between the lamp arm support 5 and the lamp arm support main rod 4 is 45° and the lamp arm support 5 is distributed on both sides of the lamp arm support main rod 4. And the lamp arm bracket total rod 4 is made of left half bracket rod 4.1 and right half bracket rod 4.2, and is provided with semicircle groove 4.3 inside left half bracket rod 4.1, right half bracket rod 4.2 inside, two semicircle grooves 4.3 Synthesize the cent...

Embodiment 2

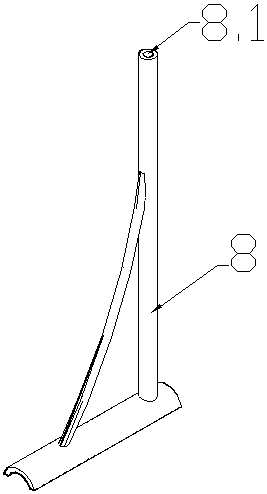

[0021] like figure 1 , figure 2 , image 3 As shown, the structure of the auxiliary rail car for spraying and baking of the street lamp lamp arm of the present invention is based on the first embodiment, and a pipe (stainless steel pipe) 6 is placed on the central accommodation hole, and the pipe 6 corresponds to the lamp arm The direction of the bracket 5 is provided with a branch pipe 6.1 penetrating into the corresponding lamp arm bracket. When baking, the high-temperature gas around the baking room is passed into the lamp arm to ensure that the lamp arm is heated evenly, especially after spraying powder on the inner hole wall of the lamp arm, the baking effect can be guaranteed; in addition, before spraying, you can Put alkaline water and clear water into the pipeline to realize the surface pretreatment of the inner hole of the lamp arm. And the base 1 is welded with a fixing frame 7 to ensure that the lamp arm 8 is placed vertically. Install the inner wall of lamp ho...

Embodiment 3

[0024] The specific structure of the auxiliary rail car for spraying and baking of the lamp arm of the street lamp in this embodiment is the same as that in the second embodiment.

[0025] The new process of processing the lamp arm of the street lamp in this embodiment is the same as that of Embodiment 2 except for the following: after pretreatment and before electrostatic spraying, the lamp arm 8 is suspended on the lamp arm bracket 5, and the pipe 6 is passed into The gas with a temperature of 35-50° C. is blown into the installation lamp hole 8.1 on the lamp arm 8 after passing through the lamp arm bracket 5 to preheat the lamp arm 8 and improve the spraying effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com