Shape-memory aluminum matrix composite material, preparation method, mobile terminal middle frame and manufacturing method

An aluminum-based composite material and mobile terminal technology, which is applied in the field of mobile terminals, can solve problems such as easy deformation and bruising, and achieve a long-lasting and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing a shape memory aluminum matrix composite material, comprising the following steps:

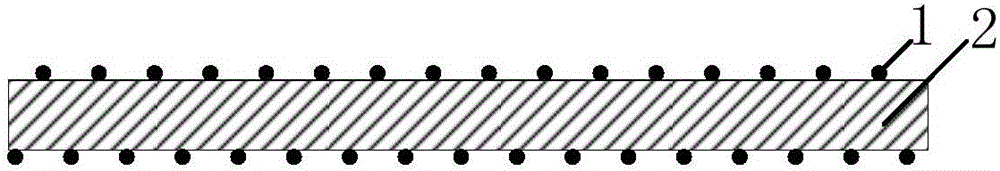

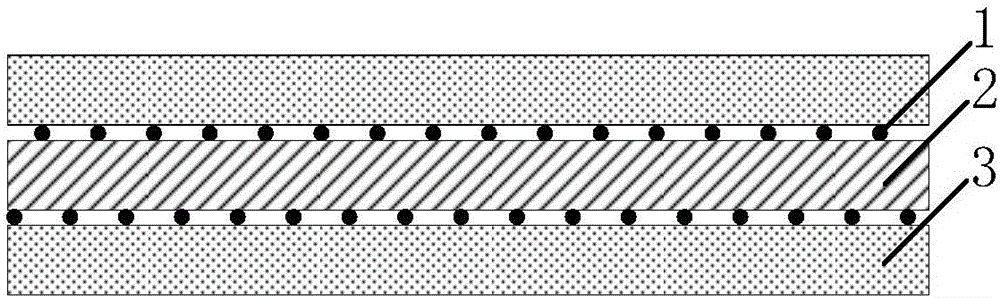

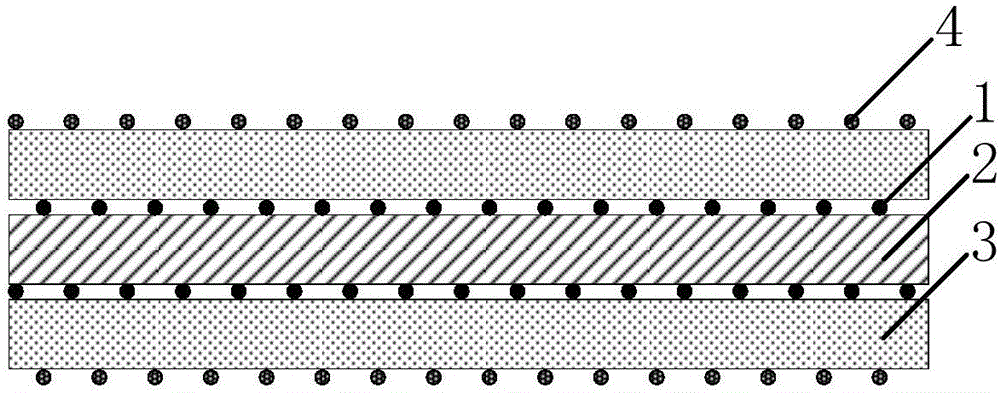

[0026] Step S1: place the shape memory alloy fiber layer and the aluminum alloy plate alternately until the preset thickness is reached, and obtain the shape memory alloy fiber and aluminum alloy plate unit to be processed; wherein, each layer of shape memory alloy fiber layer includes a plurality of Shape memory alloy fibers, the diameter of the shape memory alloy fibers is 0.1 mm to 0.2 mm, and the distance between two adjacent shape memory alloy fibers is 0.5 cm to 1.0 cm;

[0027] Step S2: hot pressing the shape-memory alloy fiber and the aluminum alloy plate unit to form a metal bond between the shape-memory alloy fiber and the aluminum alloy plate to obtain the shape-memory aluminum matrix composite material.

[0028] Compared with the prior art, in the preparation method of the shape-memory aluminum matrix composite provided by the pr...

Embodiment 1

[0055] This embodiment provides a method for preparing a shape memory aluminum matrix composite material, comprising the following steps:

[0056] Step S1: alternately place the TiNi-based shape memory alloy fiber layer and the aluminum alloy plate until the preset thickness is reached, and obtain the TiNi-based shape memory alloy fiber and aluminum alloy plate unit to be processed; wherein, each layer of TiNi-based shape memory alloy fiber layer It includes a plurality of TiNi-based shape memory alloy fibers arranged at intervals, the diameter of the TiNi-based shape-memory alloy fiber is 0.1 mm, and the distance between two adjacent TiNi-based shape-memory alloy fibers is 1.0 cm. Among the TiNi-based shape-memory alloy fibers The molar ratio of Ti to Ni is 0.95:1, and the thickness of the aluminum alloy plate is 3mm;

[0057] Step S2: Hot pressing the TiNi-based shape memory alloy fiber and the aluminum alloy plate unit to obtain the shape memory aluminum matrix composite ma...

Embodiment 2

[0059] This embodiment provides a method for preparing a shape memory aluminum matrix composite material, comprising the following steps:

[0060] Step S1: alternately place the TiNi-based shape memory alloy fiber layer and the aluminum alloy plate until the preset thickness is reached, and obtain the TiNi-based shape memory alloy fiber and aluminum alloy plate unit to be processed; wherein, each layer of TiNi-based shape memory alloy fiber layer It includes a plurality of TiNi-based shape memory alloy fibers arranged at intervals. The diameter of the TiNi-based shape-memory alloy fiber is 0.2 mm, and the distance between two adjacent TiNi-based shape-memory alloy fibers is 0.5 cm. Among the TiNi-based shape-memory alloy fibers The molar ratio of Ti to Ni is 1:1, and the thickness of the aluminum alloy plate is 1.5mm;

[0061] Step S2: Hot pressing the TiNi-based shape memory alloy fiber and the aluminum alloy plate unit to obtain the shape memory aluminum matrix composite mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com