Aircraft layout of tilt rotors/lift fan during high-speed long endurance

A technology of tilting rotor and lift fan, which is applied in the direction of aircraft, rotorcraft, vertical take-off and landing aircraft, etc. It can solve the problems of reducing the lift-drag ratio of the whole machine and the weight of the structure, and achieves increased aspect ratio and high cruise lift. The drag ratio and the stiffness of the wing structure require a small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

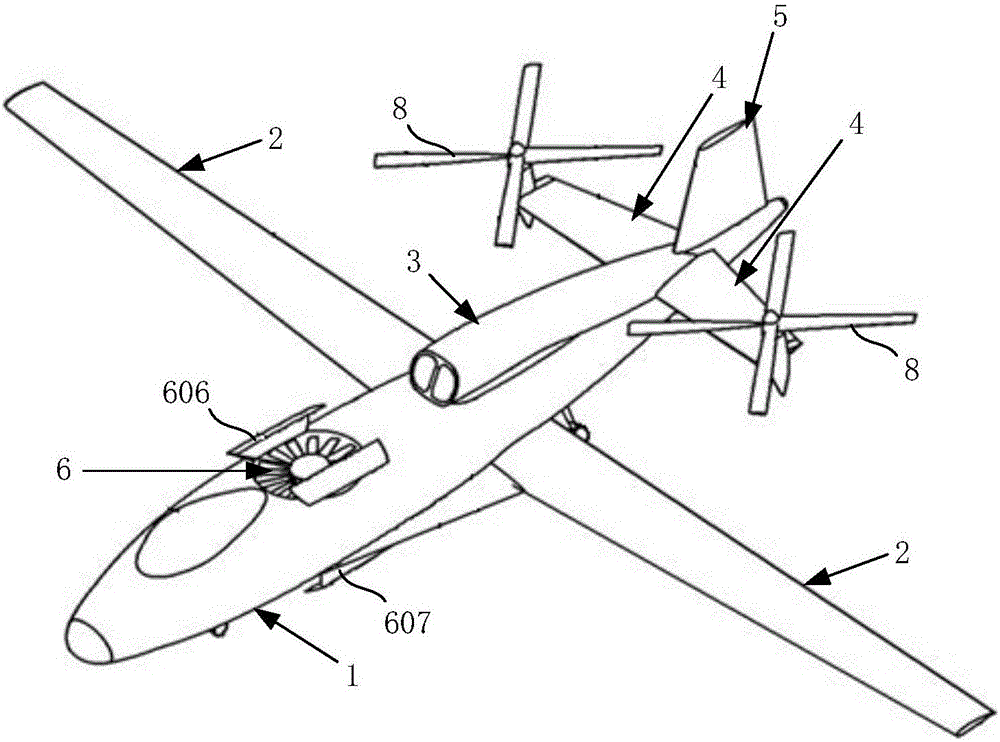

[0034] The layout of the tilt rotor / lift fan high-speed and long-endurance aircraft of the present invention is as follows: figure 1 shown. Wherein, the aircraft has the wings 2 symmetrically arranged on both sides of the fuselage 1, the engine compartment 3 designed in the middle of the fuselage 1, the horizontal tail 4 symmetrically arranged on both sides of the tail of the fuselage 1, and the vertical tail 5 arranged vertically at the tail of the fuselage 1. . An aircraft engine is installed in the above-mentioned nacelle 3 .

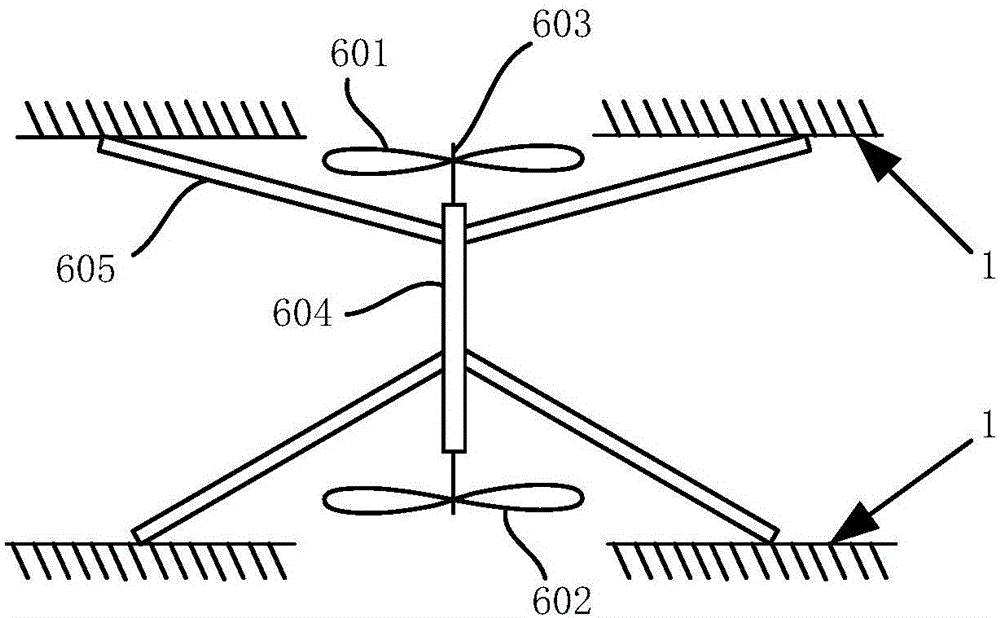

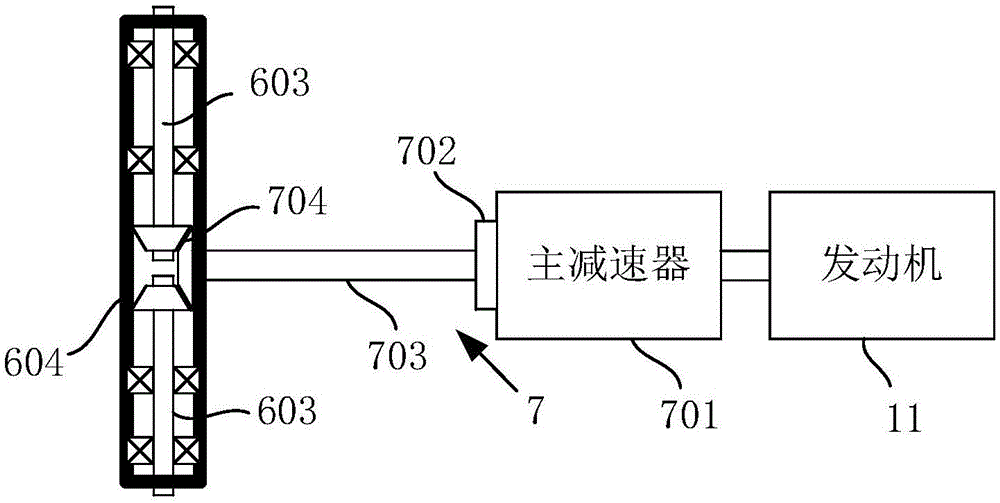

[0035] A lift fan 6 is installed in the fuselage 1 front of the aircraft, the lift fan 6 is a coaxial anti-propeller ducted fan, with an upper fan 601 and a lower fan 602, and the counter torque of itself is balanced, as figure 2 , image 3 shown. The upper fan 601 and the lower fan 602 are respectively located at the upper ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com