A switch-type carbon nanotube dispersant

A technology of carbon nanotubes and dispersants, applied in the field of switch-type carbon nanotube dispersants, to achieve the effect of excellent surface chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

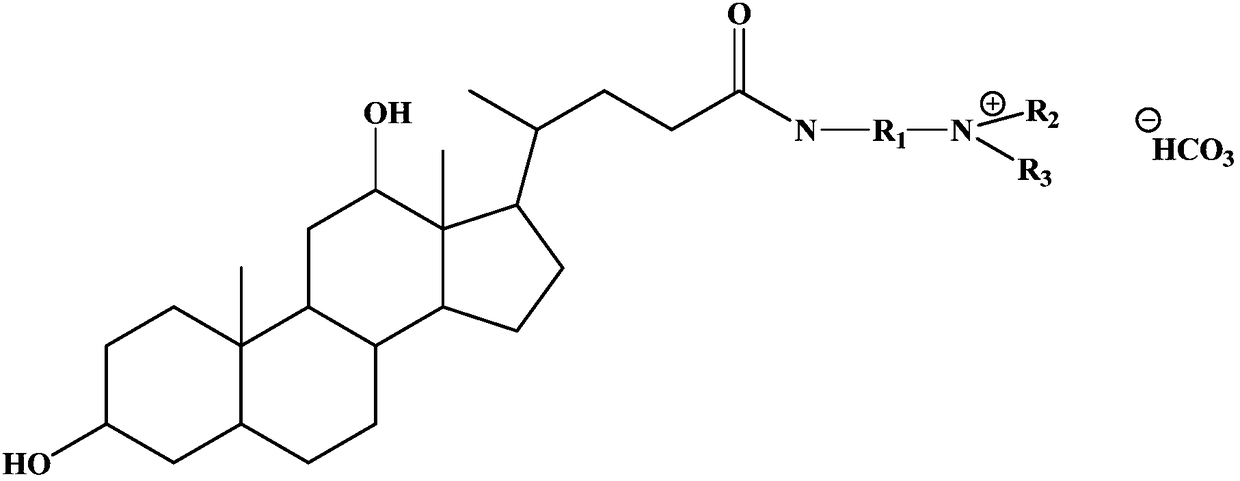

[0018] Example 1: Deoxycholic acid reacted with 10 times molar equivalents of acetic anhydride at 65°C for 30 hours to obtain a hydroxyl-protected product; the hydroxyl-protected product was reacted with 2 molar equivalents of thionyl chloride in dichloromethane at room temperature After 24 hours, the organic solvent and thionyl chloride were removed after the reaction to obtain the acid chloride product, and the acid chloride product was reacted with N,N-dimethylethylenediamine in dichloromethane for 24 hours to obtain the amidation product. The amidated product was mixed with 2% NaOH (mass percentage), stirred at room temperature for 24 hours to obtain a hydroxyl deprotected product, and carbon dioxide was introduced into the aqueous solution of the hydroxyl deprotected product to obtain deoxycholic acid amidoethylenediamine bicarbonate.

Embodiment 2

[0019] Example 2: Deoxycholic acid and 10 times the molar equivalent of hexamethyldisilazane were reacted at 65°C for 30 hours to obtain a hydroxyl-protected product; the hydroxyl-protected product was mixed with 2 molar equivalents of oxalyl chloride in dichloromethane at room temperature Under reaction for 24 hours, remove the organic solvent and oxalyl chloride after the reaction is over to obtain the acid chloride product, react the acid chloride product with N,N-dimethylbutylene diamine in dichloromethane for 24 hours to obtain the amidation product, and The amidated product was mixed with 2% NaOH (mass percentage), stirred at room temperature for 24 hours to obtain a hydroxyl deprotected product, and carbon dioxide was introduced into the aqueous solution of the hydroxyl deprotected product to obtain deoxycholic acid amidobutylene diamine bicarbonate.

Embodiment 3

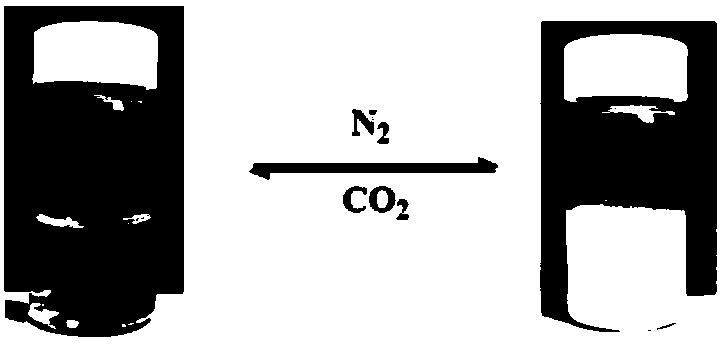

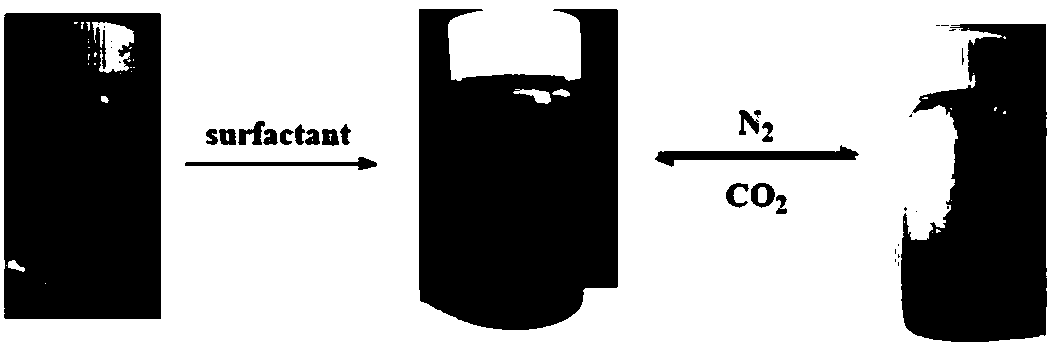

[0020] Example 3: Add 10 mg of multi-walled carbon nanotubes to 10 mL of 1% (mass percentage) dispersant deoxycholic acid amidoethylenediamine bicarbonate aqueous solution, and disperse with an ultrasonic disperser to obtain dispersed multi-walled carbon nanotubes Aqueous solution, when the aqueous solution is fed with nitrogen or heated, the dispersant decomposes to obtain an aqueous solution of agglomerated multi-walled carbon nanotubes; when the aqueous solution is fed with CO 2 And after ultrasonic dispersion, the dispersed multi-walled carbon nanotube aqueous solution is obtained again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com