Preparation method of calcium carbonate particles

A calcium carbonate and particle technology, applied in the direction of calcium carbonate/strontium/barium, etc., can solve the problem of uneven morphology of calcium carbonate particles, and achieve the effects of uniform morphology, prevention of crystal structure damage, and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

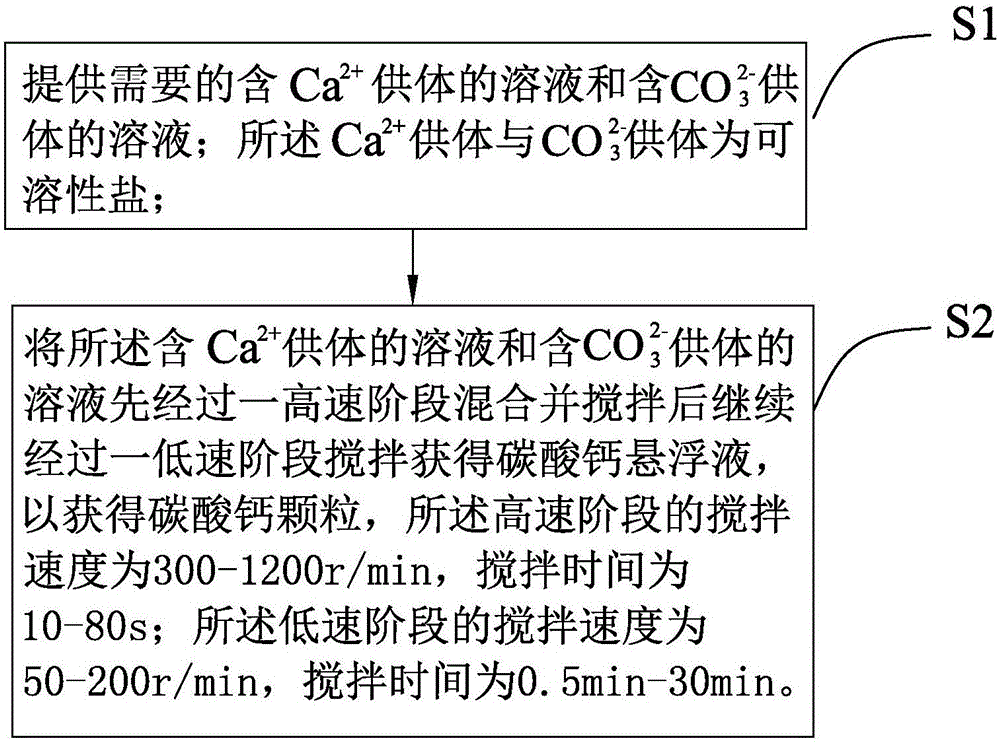

[0029] See figure 1 , The present invention provides a method for preparing calcium carbonate particles, including the steps:

[0030] Step S1: Provide the required Ca 2+ Donor's solution and containing CO 3 2- Donor’s solution, the Ca 2+ Donor and CO 3 2- The donor is a soluble salt;

[0031] Step S2: Combine the Ca-containing 2+ Donor's solution and containing CO 3 2- The solution of the donor is first mixed and stirred at a high speed stage and then continues to be stirred at a low speed stage to obtain a calcium carbonate suspension to obtain calcium carbonate particles. The stirring speed at the high speed stage is 300-1200r / min, and the stirring time is 10s- 80s; the stirring speed in the low-speed stage is 50-200r / min, and the stirring time is 0.5-30min.

[0032] In the embodiment of the present invention, in step S1, the required Ca-containing 2+ Donor's solution and containing CO 3 2- In the donor solution method, the Ca provided 2+ Donor and CO 3 2- The molar concentration ...

no. 1 Embodiment

[0051] Weigh 3.66g of calcium chloride, that is, 0.33M calcium chloride, add the calcium chloride to deionized water, and stir at 28°C for 3min to obtain a calcium chloride solution; weigh 3.50g of sodium carbonate, which is 0.33 M sodium carbonate, add the sodium carbonate to 100 mL of deionized water, and stir for 3 min at a temperature of 28° C. to obtain a sodium carbonate solution.

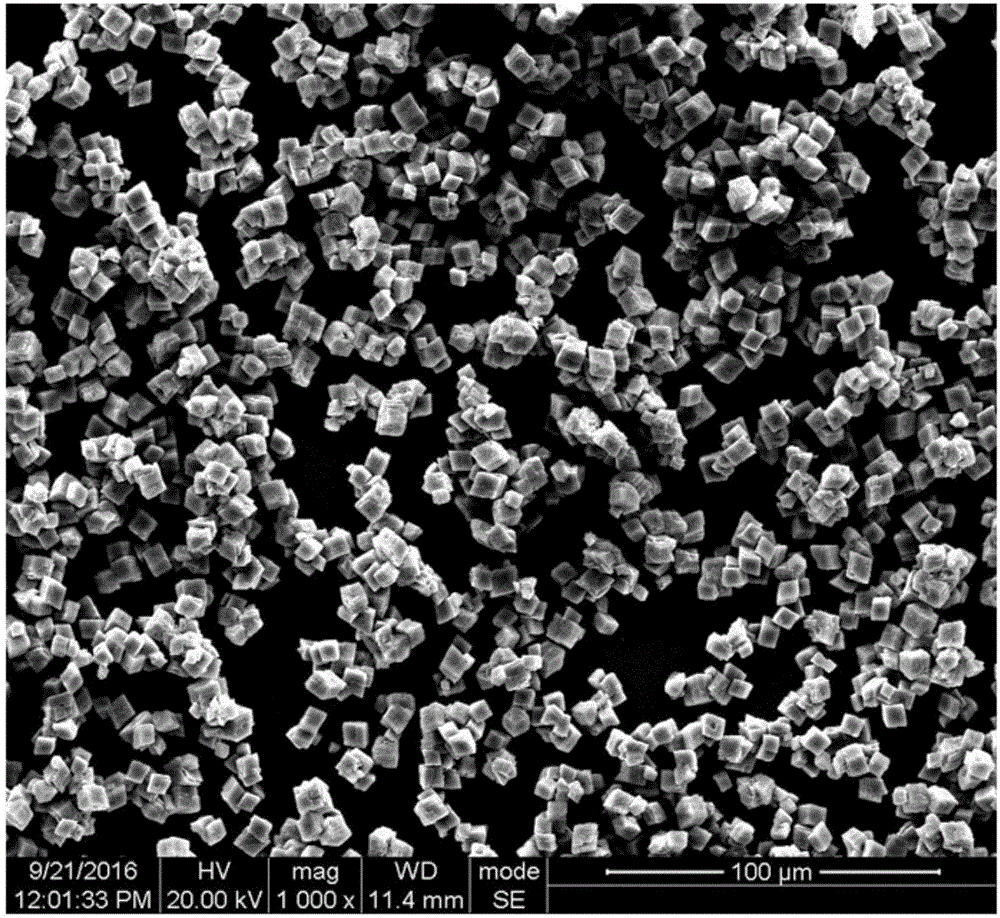

[0052] The calcium chloride solution and calcium carbonate solution obtained above were mixed and stirred at a high-speed stage at a temperature of 28°C. The stirring speed of the high-speed stage was 650r / min and the time was 30s; after the high-speed stage was mixed and stirred, it was lowered The speed continues to undergo low-speed stage stirring. The low-speed stage stirring speed is 100r / min and the time is 2min. After the low-speed stage stirring is completed, a calcium carbonate suspension is obtained;

[0053] After centrifugally washing the calcium carbonate suspension with deionized wat...

no. 2 Embodiment

[0059] The difference between the second specific embodiment and the first specific embodiment is: the stirring speed in the high-speed stage is 600r / min, and the time is 30s; after the high-speed stage is mixed and stirred, the low-speed stage is continued. The stage stirring speed is 50r / min, and the time is 2min.

[0060] Through the same test method as the above-mentioned first embodiment, the calcium carbonate particles obtained in the second embodiment have a relatively uniform morphology, and 98% of the calcium carbonate particles have a hexahedral structure. See Figure 5 When the calcium carbonate particles obtained in the second specific embodiment are enlarged 20000 times, it can be clearly observed that a single calcium carbonate particle has a regular regular hexahedral structure and is well dispersed. The side length of the regular hexahedron is 2.5-7.2um. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com