A device and method for producing light-burned magnesia from magnesite flotation concentrate powder

A light-burned magnesia and flotation concentrate technology is applied in the field of devices for producing light-burned magnesia from magnesite flotation concentrate powder, which can solve problems such as inapplicability, avoid material blockage, improve drying efficiency, and rational The effect of effective warm-up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The magnesite flotation concentrate powder used in this embodiment is the wet concentrate powder obtained through flotation separation and purification of Dashiqiao magnesite. The MgO content in the Dashiqiao magnesite is 35% to 45%. The MgO content in the flotation concentrate powder is 47.50%, and the water content is 12.0%. In this embodiment, the device and method for producing light-burned magnesia with magnesite flotation concentrate powder are adopted, and the production scale design for production is 80 tons. / day (3300kg / h), the output of producing light-burned magnesia reaches 4000~4500kg / h, the main and auxiliary furnace type structural furnace, flash drying machine, secondary preheating system used in the present embodiment, temperature error control within ±50°C.

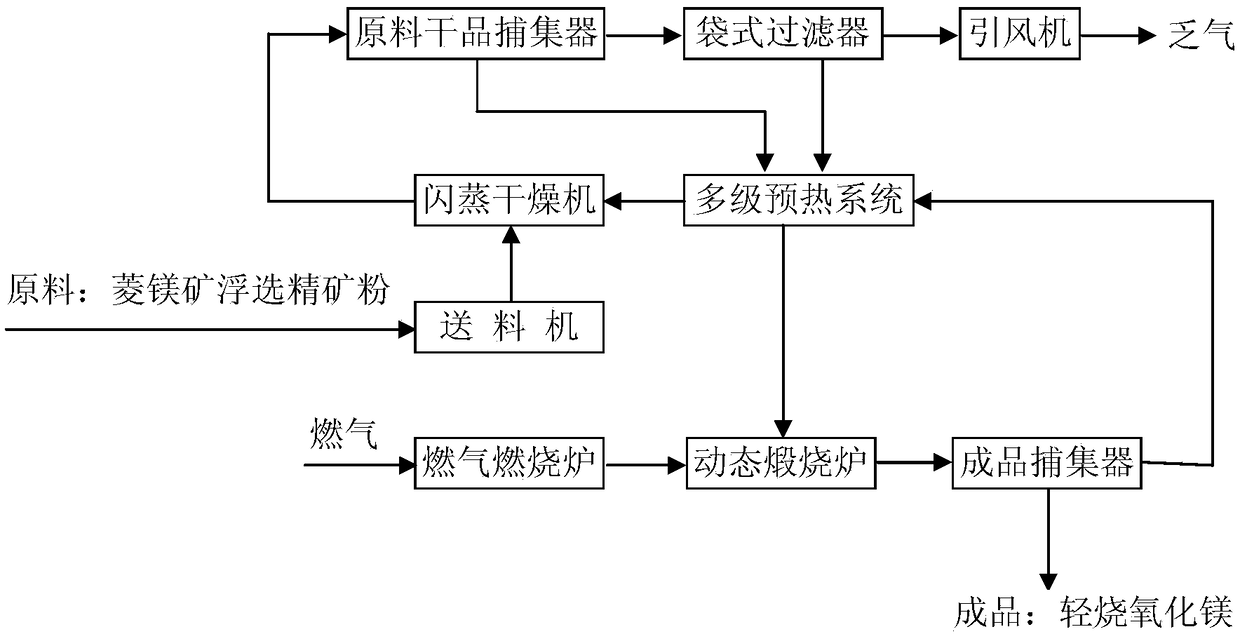

[0035] A device for producing light-burned magnesia with magnesite flotation concentrate powder, the device includes a feeder, a flash dryer, a raw material dry product collector, a secondary pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com