Gas explosion processor

A processor and detonation technology, applied in the field of steam blasting, can solve problems such as clerical errors and errors, achieve short blasting time, increase acceleration, and increase opening acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

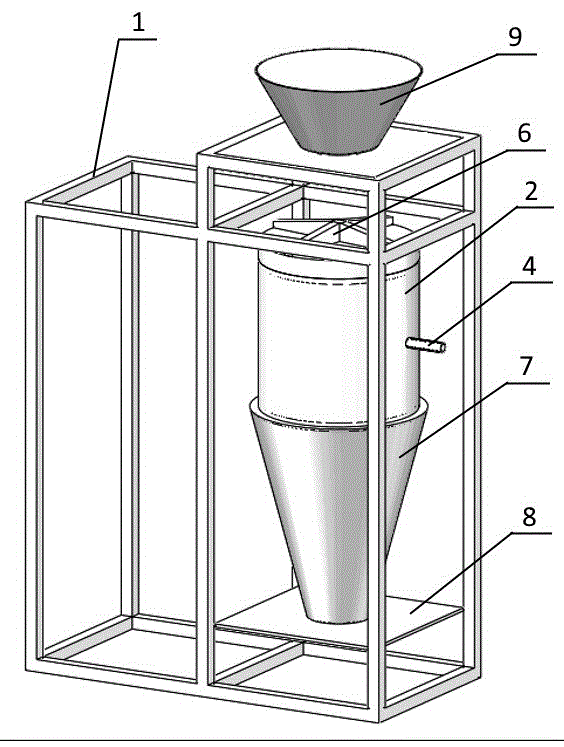

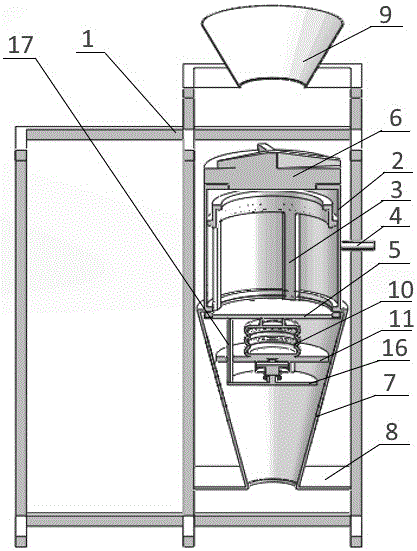

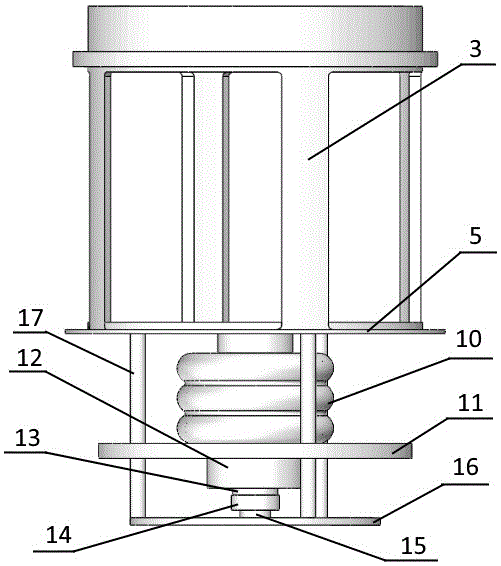

[0049] A gas detonation processor such as Figure 1-4 As shown in , including: frame (1), outer cylinder body (2), inner cylinder body (3), steam pipe (4), lower sealing end cover (5), upper sealing end cover (6), receiving bin (7), feeding bin support plate (8), feeding bin (9); it is characterized in that, also includes supporting airbag (10), airbag fixing plate (11), synchronous cylinder block (12), synchronous cylinder piston ( 13), pulse cylinder body (14), pulse cylinder piston (15), pulse cylinder piston connecting plate (16), 3 guide rods (17), elastic sealing assembly (18) and control mechanism;

[0050] The outer cylinder body (2) is fixed in the frame (1) to obtain stable support and fixation;

[0051] The inner cylinder body (3) is sleeved on the outer cylinder body (2) and slides axially, and its lower end is a fixedly connected lower sealing end cover (5), and the lower sealing end cover (5) is equipped with an elastic sealing assembly (18), It is used to seal...

Embodiment 2

[0069] The difference between a kind of gas detonation processor of the present embodiment and embodiment 1 is:

[0070] There are 4 guide rods (17);

[0071] The synchronous cylinder and / or pulse cylinder are double-acting cylinders.

[0072] The working principle and usage method of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com