Strip interface constrained damping ballast bed for subway vibration and noise reduction and preparation method thereof

A technology for vibration reduction, noise reduction, and restraint damping. It is applied to roads, tracks, ballast layers, etc. It can solve the problems of insignificant vibration reduction effect, slippage of track bed structure, and reduced vibration reduction effect, and achieve good resistance to train impact and performance. Fatigue resistance, prevention of relative slip and wavy wear, effect of increasing impact resistance and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

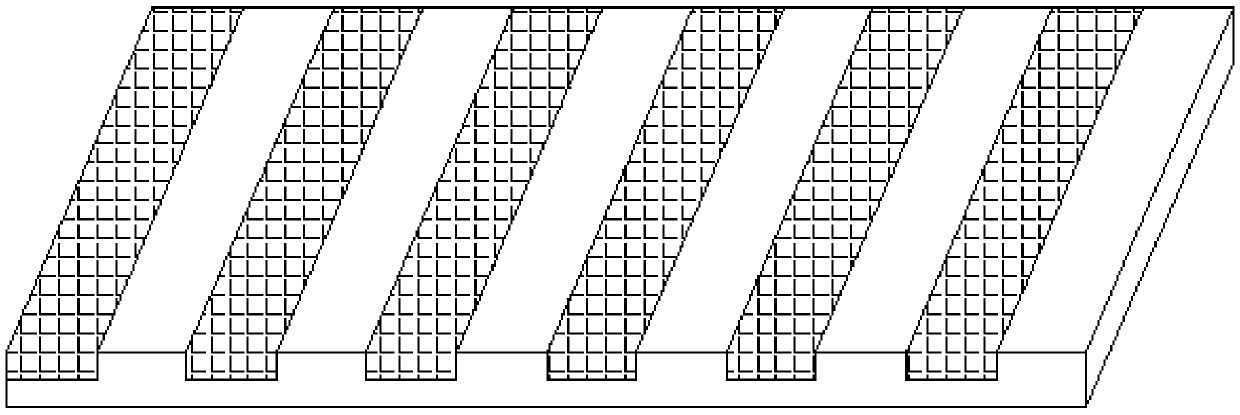

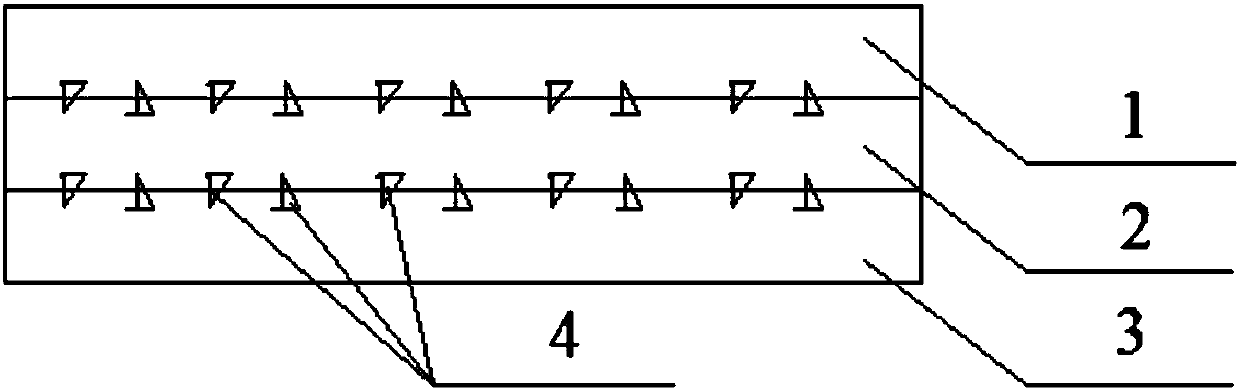

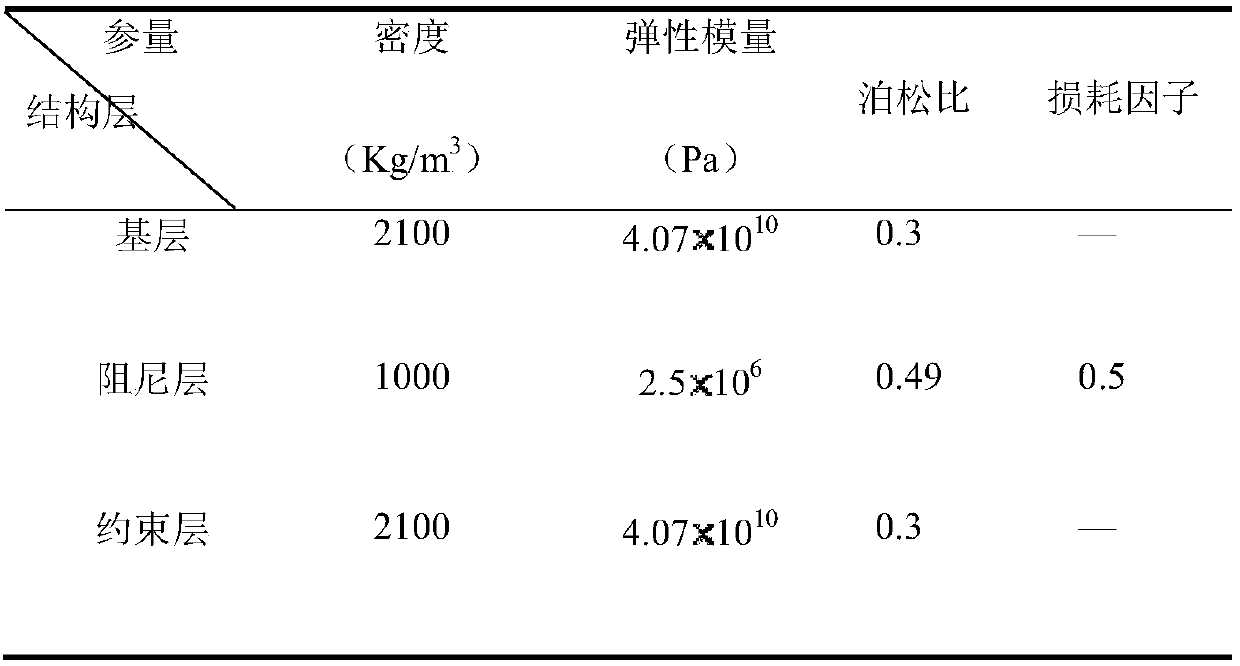

[0030] The strip interface constrained damping track bed for subway vibration and noise reduction includes a concrete base layer, a constrained layer and an intermediate layer between them. The track bed has a length of 12-15m and a width of 3-5m. The concrete base layer, the constrained layer and the middle layer are all strip-shaped, and the strips of two adjacent layers match each other; the middle layer is a multi-layer constrained damping layer, and the middle layer is composed of damping material layers arranged in sequence I. Composition of hard interlayer and damping material layer II. The damping material layer I is located on the side close to the concrete base layer, and the damping material layer II is located on the side close to the constraining layer. The damping material layer is a polyurethane-urea damping material. The hard interlayer is an epoxy resin layer with a Shore D hardness of 65.

[0031] Wherein, the strip-shaped interface is composed of a plurality...

Embodiment 2

[0040] The difference from Example 1 is that the damping track bed is constrained by the strip interface of subway vibration and noise reduction, and the hard interlayer is an epoxy resin layer with a Shore D hardness of 64. The protrusion height of the strip is 100 mm, the width of the strip is 360 mm, and the width between two adjacent strips is 380 mm. Wherein, the thickness of the damping material layer I, the hard interlayer and the damping material layer II are all 1.6 mm; the thickness of the concrete base layer and the constraining layer are both 0.25 m. The hard interlayer and the damping material layer I and the hard interlayer and the damping material layer II are provided with an emery layer embedded on the surfaces of the two, and the quantity of the emery is 4.0kg / m 2 , The particle size of the emery is 1.6mm.

[0041] The difference from Example 1 is that the preparation method of the strip interface constrained damping track bed for subway vibration and noise redu...

Embodiment 3

[0050] The difference from Example 1 is that the damping track bed is constrained by the strip interface of subway vibration and noise reduction, and the hard interlayer is an epoxy resin layer with a Shore D hardness of 66. The height of the protrusion of the strip is 110 mm, the width of the strip is 400 mm, and the width between two adjacent strips is 300 mm. Wherein, the thickness of the damping material layer I, the hard interlayer and the damping material layer II are all 2.5 mm; the thickness of the concrete base layer and the constraining layer are both 0.22 m. The hard interlayer and the damping material layer I and the hard interlayer and the damping material layer II are provided with an emery layer embedded on the surfaces of the two, and the quantity of the emery is 3.5kg / m 2 , The particle size of the emery is 1.8mm.

[0051] The difference from Example 1 is that the preparation method of the strip interface constrained damping track bed for subway vibration and noi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com