Head chute separated type ballastless track cutting bed structure for middle-strong salinized soil areas

A ballastless track, saline soil technology, applied in the direction of roads, tracks, road bottom, etc., to achieve the effects of novel structure, avoid secondary salinization, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below through specific embodiments in conjunction with the accompanying drawings.

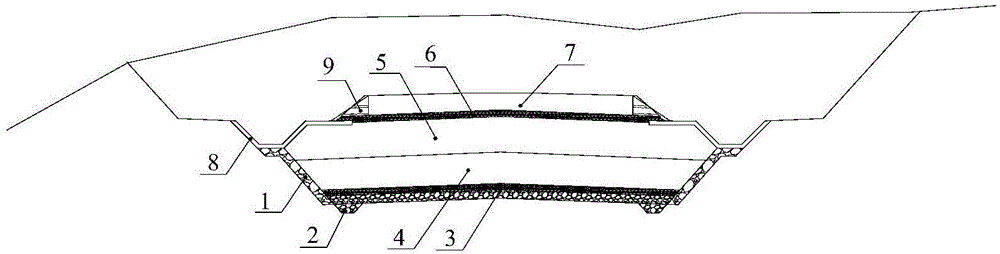

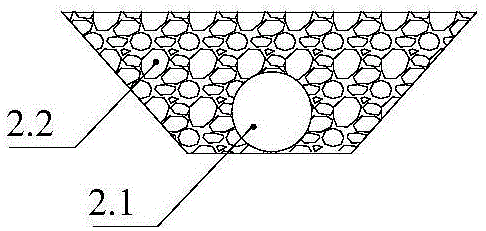

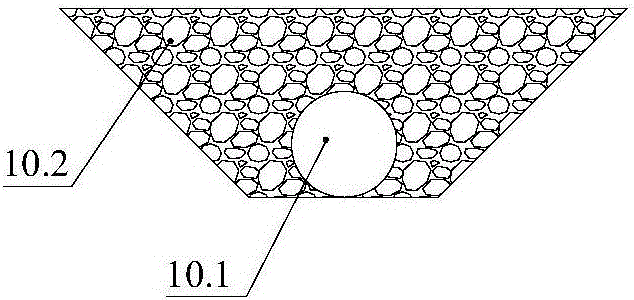

[0018] refer to figure 1 , the cut foundation bed structure of ship trough partition type ballastless track in medium-strong saline soil area, which includes: an inverted L-shaped protective layer 1, which is arranged on the side slopes on both sides of the foundation bed excavation; vertical seepage salt drainage blind ditch 2, Set at the toe of the inverted L-shaped protective layer on both sides of the foundation bed; the base partition layer 3 is set above the bottom surface of the foundation bed and the vertical water seepage and salt drainage blind ditch 2; above the base partition layer 3, the substructure of the foundation bed layer is laid sequentially from bottom to top Layer 4, structure layer 5 on the bottom layer of the foundation bed, partition layer 6 of the foundation bed, surface layer 7 of the foundation bed; drainage ditc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com